菲律宾客户购买20TPD工业稻米铣床以开始稻米铣削业务

菲律宾的客户是谷物行业的一位企业家,其原料材料和现有工厂设施均稳定,并计划进入稻米铣削行业。客户想引入高效的工业稻米铣床工厂,以将自己的生稻谷(Raw Paddy)处理成高质量的水稻产品,以满足当地市场需求并实现盈利能力。

设备选择基础

在分析了客户的需求之后,我们建议使用20TPD(每天吨)的稻米铣削单元。该单元具有适中的容量,适合客户的初始业务规模,并且具有扩展的潜力。 Thit Thit Wustustail Rice Miling机厂的核心优势包括高生产能力,稳定的运营,易于操作和低维护成本,这是客户实际需求的理想选择。

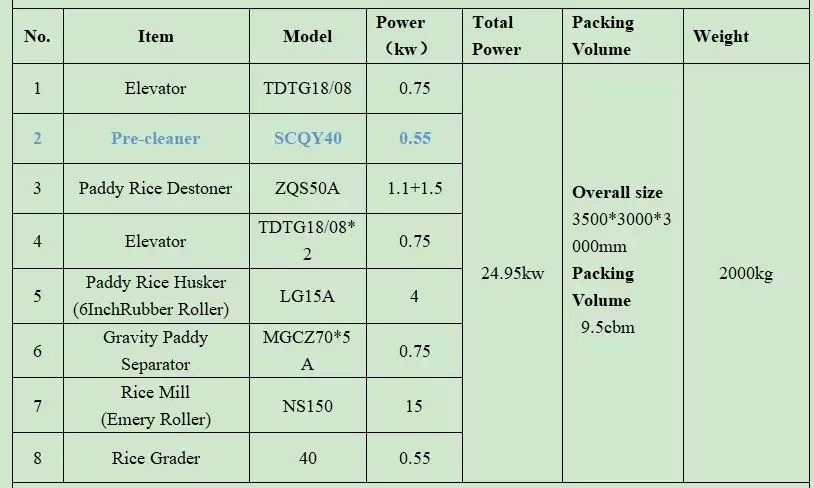

我们为客户提供了20TPD稻米铣削单元的完整配置,包括:

- De-Stoner:从稻田中取出石头和其他杂质,以确保原材料的纯度。

- 船体:有效完成水稻壳过程。

- 重力米分离器:单独的糙米和稻米。

- 米粉机:将糙米加工成白米饭,以确保米饭的外观和味道。

- 分级筛子:根据粒径将大米进行分级,以确保产品一致性。

该程序具有以下优点:

- 高容量:20TPD容量可以满足客户的初始生产需求,同时保留未来扩展的空间。

- 易于操作:这台工业稻米铣床的设计旨在用户友好,易于操作和维护,并且适合首次进入该行业的客户。

- 稳定且可靠的:设备采用高质量的材料和先进的技术来确保长期稳定运行并降低客户的生产风险。

运输和安装

合同签署后,我们迅速组织了设备的生产和包装,并使用专业运输解决方案将设备运送到菲律宾。为了确保设备安全到达,我们已经为设备进行了防潮和防震处理,并提供了详细的运输跟踪服务。

20TPD工业稻米铣床到达客户工厂后,我们指导客户安装和调试设备。我们提供详细的操作培训,包括:

- 设备的基本操作过程

- 每日维护和维修方法

- 双语(中文和英语)操作手册

- 解决常见问题的故障排除技术

在以上帮助下,客户可以轻松顺利地开始他的白米生产业务。