فروش دستگاه آسیاب آرد ذرت و بلغور ذرت

دستگاه آسیاب بلغور ذرت عمدتاً برای تولید بلغور ذرت و آرد ذرت استفاده میشود. معمولاً، پس از پردازش توسط دستگاه تولید بلغور ذرت، سه محصول نهایی دریافت میکنید. این محصولات به ترتیب بلغور ذرت درشت، بلغور ذرت ریز و آرد ذرت هستند. علاوه بر این، نسبت محصول نهایی قابل تنظیم است. بلغور ذرت و آرد ذرت تولید شده توسط دستگاههای ما برای اهداف بسیاری قابل استفاده است، که میتوانند مستقیماً مصرف شوند یا در صنایع غذایی برای تهیه تنقلات و دسرها استفاده شوند.

این دستگاه نه تنها در کارگاههای کوچک روستایی بلکه در خطوط تولید بزرگ مانند کارخانههای آرد ذرت نیز قابل استفاده است. این دستگاه میتواند از جنبههای مختلفی برای سرمایهگذاران درآمد ایجاد کند. علاوه بر این، دستگاههای تولید بلغور ذرت ما به بسیاری از کشورها و مناطق صادر شدهاند. از جمله فیلیپین، سریلانکا، تیمور شرقی، بنگلادش، کنیا، بورکینافاسو، آنگولا، زامبیا و غیره.

فروش داغ بلغور ذرت و دستگاه آسیاب -انواع دستگاه آسیاب ذرت

به عنوان یک تولید کننده و تامین کننده حرفهای کشاورزی، ما انواع مختلفی از ماشین آلات کشاورزی را داریم. در مورد دستگاههای آسیاب بلغور ذرت، ما پنج مدل را برای انتخاب شما داریم. آنها T1، T3، PH، PD2، C2 هستند. اینها دستگاههای تولید بلغور ذرت بسیار محبوبی هستند که هر کدام ویژگیهای خاص خود را دارند.

دستگاه آسیاب و آسیاب ذرت در مقیاس کوچک T1

این دستگاه بلغور ذرت می تواند از موتور الکتریکی یا موتور دیزلی به عنوان سیستم قدرت با ظرفیت 200 کیلوگرم در ساعت استفاده کند. علاوه بر این، دستگاه آسیاب بلغور ذرت نمی تواند همزمان پوست کندن ذرت و ساخت بلغور را انجام دهد. دستگاه ابتدا پوست کنده و سپس سنگ ریزه درست می کند. عملکرد پایداری دارد و برای کارگاه های کوچک روستایی مناسب است.

| مدل | T1 |

| قدرت | موتور الکتریکی 7.5 کیلووات یا موتور دیزلی 18 اسب بخار |

| ظرفیت | 200 کیلوگرم در ساعت |

| وزن | 350 کیلوگرم |

| اندازه | 850*500*1180 میلیمتر |

| وزن ناخالص | 520 کیلوگرم برای مدل موتور الکتریکی؛ 524 کیلوگرم برای مدل دیزلی |

دستگاه پوست کن و بلغور ذرت صنعتی T3

دستگاه آسیاب ذرت تایزی دارای دو موتور می باشد که می تواند همزمان پوسته کنده و سنگ ریزه درست کند. ظرفیت 300-400 کیلوگرم در ساعت را دارد. همچنین، یک گردباد در پشت برای جمع آوری پوسته و گرد و غبار وجود دارد. به این ترتیب، کل فرآیند تمیزتر است.

| مدل | T3-A |

| قدرت | 7.5 کیلووات + 4 کیلووات |

| ظرفیت | حدود 400 کیلوگرم در ساعت |

| وزن | 680 کیلوگرم |

| اندازه | 2300*1400*1300 میلیمتر |

| تذکر دهید | با 2 موتور الکتریکی و 1 سیکلون |

علاوه بر این، این نوع دستگاه آسیاب ذرت میتواند با آسانسور ترکیب شود و در جهان نیز محبوب است. ما یک دستگاه آسیاب ذرت نوع T3 با آسانسور به تیمور-لسته صادر کردیم. اگر علاقهمند هستید، خوش آمدید که بلافاصله با ما تماس بگیرید!

علاوه بر مدلهای معمولی فوق، دستگاه تولید بلغور ذرت ما با آسانسور نیز قابل استفاده است که راحتتر و سریعتر است و میتوانید به وضوح از فرآیند فرآوری ذرت مطلع شوید.

| مدل | T3-B |

| قدرت | 7.5 کیلووات + 4 کیلووات |

| ظرفیت | حدود 400 کیلوگرم در ساعت |

| وزن | 680 کیلوگرم |

| اندازه | 2300*1400*1300 میلیمتر |

| قدرت دوگانه آسانسور | 0.75 کیلووات |

| تذکر دهید | با ۳ موتور الکتریکی و ۱ سیکلون |

علاوه بر این، دستگاه آسیاب ذرت ما میتواند با یک دستگاه تمیزکننده ذرت ترکیب شود تا به طور همزمان مقادیر زیادی ذرت را پردازش کند. تصویر کارخانه دستگاه در زیر نشان داده شده است:

دستگاه بلغور ذرت با کیفیت PH

این بسیار شبیه به T3 است، تفاوت این است که دستگاه آسیاب ذرت PH سیکلون ندارد.

| مدل | PH |

| قدرت | موتور الکتریکی ۱۱ کیلووات |

| ظرفیت | حدود 200-300 کیلوگرم در ساعت |

| وزن | 510 کیلوگرم |

| اندازه | 2000*650*1300 میلیمتر |

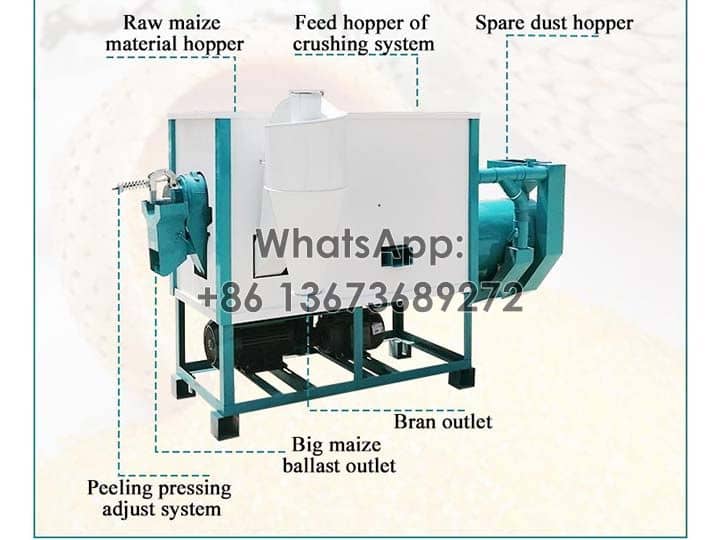

ماشین آلات ساخت بلغور ذرت پیشرفته PD2

این نوع دستگاه بلغور ذرت دارای آسانسور دوبل است که می تواند ذرت را با سرعت و کارایی بیشتری آسیاب کند.

| مدل | PD2 |

| قدرت | 15 کیلووات |

| ظرفیت | 400 کیلوگرم در ساعت |

دستگاه آسیاب ذرت چند منظوره C2

نسبت به بقیه مقرون به صرفه تر است.

| مدل | C2 |

| قدرت | 7.5 کیلو وات |

| ظرفیت | حدود 200 کیلوگرم در ساعت |

| وزن | 400 کیلوگرم |

| اندازه | 1900*500*1200 میلیمتر |

فیلم کار دستگاه بلغور و آرد سازی صنعتی ذرت

بلغور ذرت چگونه ساخته می شود؟ – فرآیند تولید بلغور ذرت

با توجه به اصل دستگاه آسیاب بلغور ذرت، در فرآیند تولید بلغور ذرت، ابتدا پوست کنده، سپس بلغور را بسازید و در نهایت محصول نهایی را دریافت کنید.

لایه برداری

دستگاه لایه بردار شامل چاقوی لایه بردار و درج فشار لایه برداری می باشد. در میان آنها یک صفحه لایه بردار در چاقوی لایه بردار وجود دارد. صفحه فشار نقش خشک کردن، تمیز کردن و راندمان بالا را ایفا می کند.

میخچه ها را در قیف قرار دهید و سپس موتور را روشن کنید. کار لایه برداری آغاز خواهد شد. ذرت ها پوست گرفته و به چند تکه خرد می شوند. همچنین میکروب های سیاه رنگ از بین می روند.

ساخت بلغور

دستگاه آسیاب بلغور ذرت دارای هسته آسیاب، دسته قابل تنظیم، دسته قفل است. بر اساس خواسته های خود، می توانید دسته را برای رسیدن به اهداف خود تنظیم کنید.

محصولات تمام شده

معمولاً سه محصول وجود دارد: بلغور بزرگ، بلغور کوچک و آرد ذرت. پس از گرفتن بالاست ذرت بزرگ، سپس با استفاده از دستگاه سنگ ریزه، سه جداکننده می توانند محصولات نهایی را به سه نوع تقسیم کنند. نسبت را می توان با توجه به نیاز شما تنظیم کرد.

مزایای دستگاه آسیاب آرد و بلغور ذرت اتوماتیک

- تکمیل خودکار لایه برداری، سنگ ریزه و آسیاب آرد، صرفه جویی در کار.

- راندمان بالا، عملکرد پایدار، کیفیت فوق العاده.

- نسبت قابل تنظیم محصولات نهایی که نیازهای مختلف را برآورده می کند.

- با آسیاب های مختلف ذرت موجود، می توانید یک دستگاه آسیاب دانه ذرت مناسب را انتخاب کنید.

- طراحی منحصر به فرد پیشرفته، مطابق با روند بازار.

لیست قطعاتی که به راحتی آسیب می بینند دستگاه آسیاب ذرت

در فرآیند تولید دانه های ذرت، برخی از قطعات به راحتی شکسته می شوند. لیستی برای نشان دادن به شما وجود دارد و باید بدانید که قطعات شکستنی به طور جداگانه عرضه می شود.

| شماره سریال | نام قطعه | مواد | واحد | مقدار |

| 1 | هسته سنگ زنی | چدن آلیاژی | مجموعه | 1 |

| 2 | غلتک | چدن سرد | مجموعه | 2 |

| 3 | چاقوی برخاستن | چدن مقاوم در برابر سایش | قطعه | 1 |

| 4 | صفحه لایه برداری | 45# ورق فولادی | قطعه | 1 |

| 5 | B1300 ناخالص | لاستیک | قطعه | 2، 3 |

| 6 | برس، پارچه | / | قطعه | 2، 1 |

| 7 | Grits machine 1211 | / | مجموعه | 2، 1 |

| 8 | دستگاه لایه بردار 307 | / | مجموعه | 2، 1 |

تعمیر و نگهداری دستگاه آسیاب ذرت ذرت

- بست ها و بلبرینگ ها باید به طور منظم بازرسی شوند. قطعات سست آسیب دیده باید به موقع تعویض یا تعمیر شوند.

- تمیز کردن منظم بلبرینگ ها، کلاچ ها و قطعات چرخان. کمبود روغن روان کننده نداشته باشید.

- هسته سنگ زنی، غلتک، چاقو، صفحه نمایش باید به طور منظم بازرسی شود.

- مرتباً بررسی کنید که آیا مهره دو سر غلتک در دستگاه پوست کن شل است یا خیر و وقتی شل شد آن را سفت کنید.

مورد موفق: صادرات دستگاه آسیاب دانه ذرت به بنگال

در ژانویه امسال، ما از مشتریان بنگلادشی استعلام دریافت کردیم. پس از گفتگو با او، متوجه شدیم که او هزینه کافی برای کارخانه فرآوری ذرت را ندارد. بنابراین، او تصمیم گرفت یک دستگاه مستقل برای تولید خریداری کند. همچنین، او یک مزرعه ذرت برای فروش بلغور ذرت و آرد ذرت دارد. با اطلاع از این موضوع، مدیر فروش ما دستگاه تولید بلغور ذرت T3 با کیفیت بالا را به او توصیه کرد. علاوه بر این، او آسیاب کوچک کوبیدن ساقه ذرت را برای فروش دید و این دستگاه را درخواست کرد. در نهایت، او 1 دستگاه آسیاب بلغور و آرد ذرت و 5 دستگاه آسیاب کوچک ذرت را سفارش داد.

نظرات مشتریان در مورد دستگاه آسیاب ذرت ذرت

ما از دریافت بازخورد مثبت از مشتریان خود در فیلیپین پس از استفاده از دستگاه تولید بلغور ذرت بسیار خرسندیم. آنها راندمان بالا، ثبات و تطبیق پذیری دستگاه را در عملکرد واقعی تجربه کردند و از عملکرد عالی آن بسیار قدردانی کردند. از طریق ویدیوی بازخورد ارسال شده توسط آنها، ما می توانیم عملکرد عالی دستگاه تولید بلغور ذرت را در تمیز کردن، پوست کندن، جنین زدایی، خرد کردن، سنگ ریزه سازی، درجه بندی و پرداخت، انتخاب هوا و گردگیری و سایر جنبه ها تجسم کنیم.

بازخورد رضایتبخش مشتریان ما در فیلیپین نه تنها کیفیت و قابلیت اطمینان بالای محصولات ما را تایید میکند، بلکه عزم ما را برای ادامه ارائه راهحلهای فرآوری ذرت با کیفیت بالا تقویت میکند.

سوالات متداول در مورد دستگاه پوستکنی ذرت و آسیاب گندم ذرت

شما ممکن است هنگام انتخاب یک دستگاه با انواع مختلفی از سردرگمی مواجه شوید. من یک سوالات متداول ویژه درباره دستگاههای آسیاب ذرت نوشتهام که میتواند به شما کمک کند. امیدوارم این اطلاعات به شما کمک کند.

بیایید و برای جزئیات بیشتر ماشین با ما تماس بگیرید!

علاقه مندید با ذرت چه کار کنید؟ بیا و با ما تماس بگیر ما همان بهترین پیشنهاد را به شما خواهیم داد!