Torréfacteur combiné de coquilles d'arachide 6BHX-28000 pour le Brésil, traitement à grande échelle

En janvier 2026, notre client brésilien a commandé une décortiqueuse combinée d'arachides 6BHX-28000 chez Taizy. Elle a une capacité de ≥6000 kg/h et un taux de nettoyage ≥99 %, ce qui améliore considérablement l'efficacité de 3 à 4 fois et permet également d'économiser des coûts.

L'utilisateur final possède une usine de traitement d'arachides, des terres agricoles, et une machine de récolte d'arachides, et cherchait à améliorer la section de décorticage avec une décortiqueuse combinée à haute capacité et fiable, adaptée aux conditions brésiliennes. Avant de passer la commande, le client a également organisé une visite de son personnel à l'usine. Voir les détails ci-dessous.

Inspection stricte de l'usine avant achat

Avant de passer la commande, le client brésilien a organisé une inspection professionnelle de l'usine. L'inspecteur a soigneusement vérifié l'atelier de production, la zone d'assemblage, et le processus de test, prenant des photos de presque chaque coin de l'usine.

Un rapport d'inspection détaillé a ensuite été préparé et soumis à l'utilisateur final au Brésil, jouant un rôle clé dans la décision d'achat finale.

Principales préoccupations de l'utilisateur final concernant la décortiqueuse d'arachides combinée

Lors de la communication, l'utilisateur final s'est principalement concentré sur des facteurs pratiques et à long terme, notamment :

- Si le La tension correspond à la norme brésilienne (220V, 60Hz, triphasé)

- Comment la grande machine serait chargée en toute sécurité dans des conteneurs

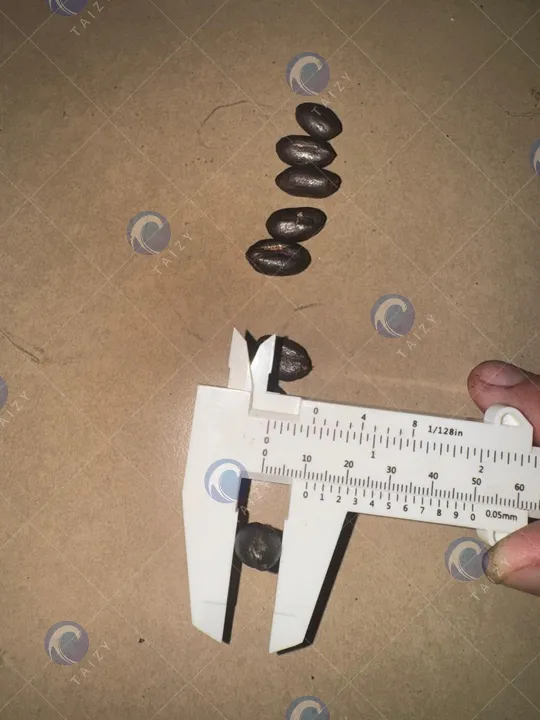

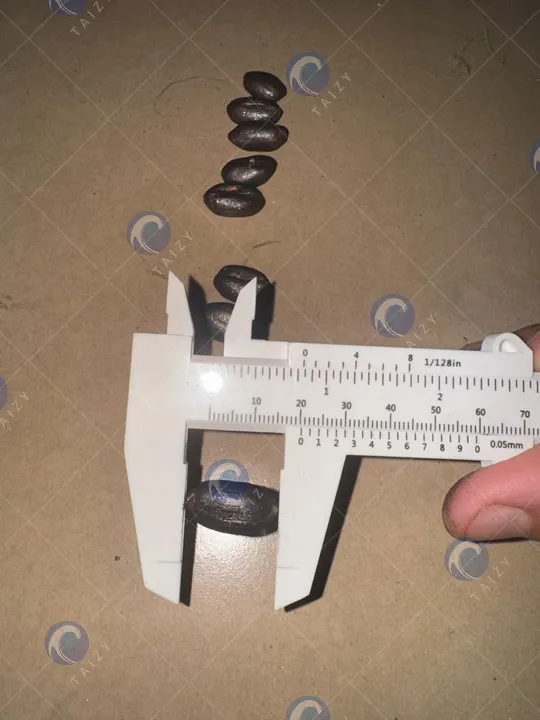

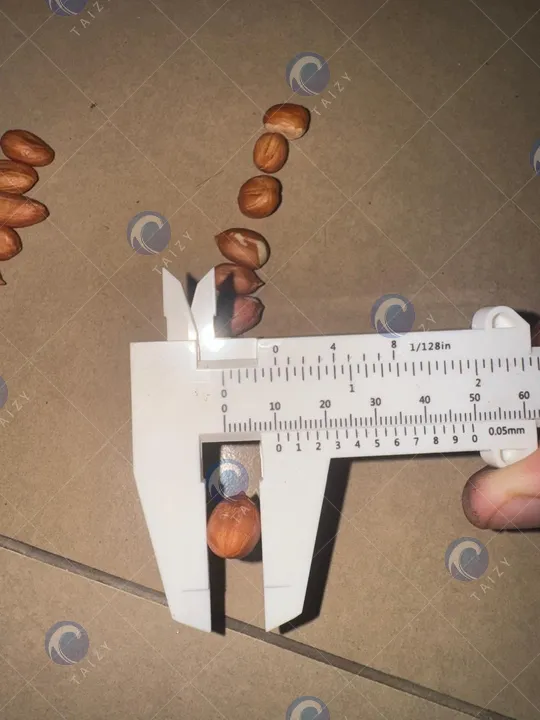

- Que les tailles d'écran peuvent être ajustées pour différentes variétés d'arachides

- Efficacité de décorticage, taux de casse, et taux de perte en fonctionnement continu

Ces préoccupations sont courantes pour les grands transformateurs d'arachides au Brésil.

Modèle recommandé : décortiqueuse combinée d'arachides 6BHX-28000

Après évaluation technique, la 6BHX-28000 décortiqueuse et nettoyeuse d'arachides combinée a été sélectionnée.

Principaux paramètres techniques :

- Capacité : ≥6000 kg/h

- Taux de nettoyage : ≥99%

- Taux de bombardement : ≥99%

- Taux de perte : ≤0,5%

- Taux de casse : ≤5%

- Humidité adaptée des arachides : ~10%

- Tension : 220V, 60Hz, triphasé

- Dimensions : 2750 × 1800 × 3360 mm

- Poids total : 2380 kg

Cette machine intègre le nettoyage et le décorticage dans un seul système, ce qui la rend idéale pour les grandes usines d'arachides au Brésil.

Support technique et solutions personnalisées

Notre équipe technique a fourni des explications détaillées sur le choix de la taille d'écran, la configuration de la tension, et les plans de chargement des conteneurs. Des solutions personnalisées ont été proposées en fonction de la taille des arachides de l'utilisateur final et de la disposition de la production, garantissant une installation et un fonctionnement sans problème après l'arrivée.

Commande confirmée avec une grande confiance

Grâce à une inspection transparente de l'usine, une communication technique claire, et la performance éprouvée de la machine, le client brésilien a confié sa commande. Cette coopération renforce encore la réputation de Taizy en tant que fabricant fiable de décortiqueuses combinées d'arachides pour le Brésil.

Contactez-nous pour votre projet de décorticage d'arachides !

Si vous recherchez une décortiqueuse d'arachides combinée au Brésil ou si vous prévoyez de mettre à niveau votre ligne de traitement d'arachides, n'hésitez pas à nous contacter.

Dites-nous votre capacité, tension, type d'arachide, et conditions de l'usine, et notre équipe recommandera la solution la plus adaptée à votre projet.