Loji Pemprosesan Kilang Padi 60TPD

Kilang Pemprosesan Padi 60TPD ialah peralatan pemprosesan padi dengan kapasiti 60 tan sehari. Unit pemprosesan kilang padi ini menampilkan kadar tinggi beras halus dan kadar patah yang rendah hasil daripada teknologi canggih. Ia mengintegrasikan penyingkiran batu, pengupasan padi, pengilangan padi, penggredan padi, pengisihan warna, dan pembungkusan.

Jadi, ia adalah kilang mesin kilang padi yang bagus untuk kilang pengilangan padi dan pemilik ladang. Juga, kami boleh menyediakan loji kilang padi lengkap 60tpd mengikut permintaan anda. Selain itu, mesin pengisar padi komersial ini dibekalkan terus oleh kilang, jadi kualitinya boleh terjamin.

Adakah anda mempunyai minat dalam peralatan mengisar padi? Selamat datang untuk menghubungi kami untuk maklumat lanjut!

Apakah mesin yang digunakan dalam mengisar padi?

Kilang pemprosesan kilang padi 60tpd kami datang dalam konfigurasi berbeza, dengan konfigurasi berbeza dipasangkan dengan bilangan mesin yang berbeza, tetapi secara umumnya, peralatan dalam unit pengilangan adalah lebih kurang sama.

Senarai mesin yang digunakan dalam kilang padi ditunjukkan di bawah:

Prapembersih & Penyingkir Batu: Menyingkirkan batu, tanah, jerami, biji rumput dan kekotoran lain daripada padi. Menggunakan tapis dan pengisihan angin, ia memastikan padi yang memasuki proses seterusnya bersih dan bebas kekotoran.

Pengupas Padi: Memisahkan kulit luar (sekam) daripada kernel dalam (beras perang) padi menggunakan daya mekanikal untuk merealisasikan proses pengupasan.

Pengasing Padi Graviti: Memisahkan campuran (beras perang dan dedak) yang diperoleh selepas pengupasan dengan berkesan, untuk mengasingkan beras perang daripada dedak dan meningkatkan ketulenan beras perang.

Mesin Pengilangan Padi: Mengguna pakai prinsip pengilangan, lapisan dedak pada permukaan beras perang secara beransur-ansur disingkirkan tanpa merosakkan endosperma nasi, dan beras putih diperoleh. Bergantung pada keperluan proses, ia mungkin perlu melalui beberapa proses penggilapan untuk memastikan kualiti.

Mesin Penggilap: Menggilap beras yang dikilang untuk menyingkirkan sisa dedak mikroskopik dan memberikan beras penampilan yang licin dan berkilat untuk meningkatkan nilai komersialnya.

Penggred Padi: Mengikut saiz, bentuk dan kualiti zarah padi, penapisan dan pengelasan dijalankan untuk memastikan produk akhir mempunyai spesifikasi yang seragam dan memenuhi keperluan pasaran yang berbeza untuk saiz bijian padi.

Pengisih Warna: Mengenal pasti dan menolak produk cacat seperti bijirin berwarna berbeza dan bijirin berpenyakit melalui sensor fotoelektrik, untuk meningkatkan kualiti keseluruhan dan keselamatan makanan beras siap.

Mesin Pembungkus: Penimbangan, pengisian, pengedapan dan penandaan automatik, melengkapkan pembungkusan produk yang standard, yang mudah untuk pengangkutan, penyimpanan dan penjualan.

Parameter Teknikal Loji Kilang Padi Moden

| Jenama | Taizy |

| Nama mesin | 60TPD loji kilang padi |

| Model | MCTP60 |

| Kapasiti | 2200-2600kg/j |

| Bijirin yang berkenaan | Beras padi |

| kuasa | 143kw |

| Saiz | 13500*2900*4500mm |

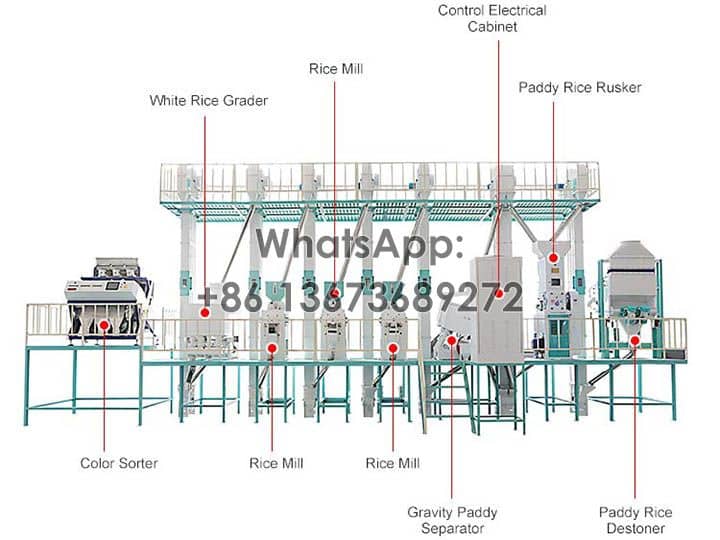

Struktur Loji Pemprosesan Kilang Padi Auto 60tpd untuk Dijual

Di Syarikat Mesin Taizy, kilang kilang padi moden 60tpd untuk dijual termasuk pembersih, penghancur batu, pemetik padi, tiga mesin kilang padi, penggred padi putih.

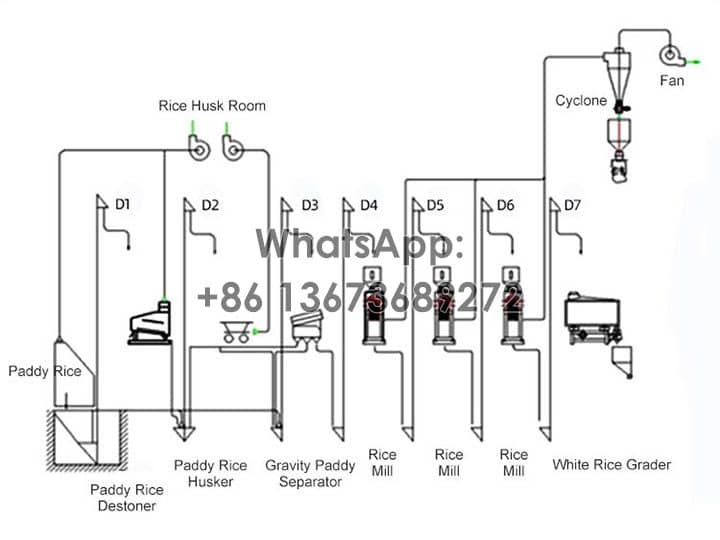

Carta Aliran Proses Loji Pemprosesan Kilang Padi

Daripada carta alir ini, anda boleh melihat bagaimana loji pengisar padi berfungsi. Ia amat membantu anda memahami proses kerja dan membiasakan diri dengan kilang mesin.

Kelebihan Mesin Kilang Padi Gabungan

- Mesin individu untuk kilang padi 60tdp dipamerkan dalam satu baris, kemas dan cantik.

- Bahagian pengilangan padi peralatan mengguna pakai teknologi pengilangan padi canggih, suhu beras rendah, dedak kecil, dan kadar pecah rendah.

- Operasi utama tertumpu pada satu sisi, mudah untuk beroperasi.

- Penjimatan tenaga, perlindungan alam sekitar, operasi mudah, penyelenggaraan yang mudah dan ketahanan.

- Kapasiti besar, kelajuan pantas, prestasi yang stabil.

- Kolokasi yang berbeza. Kami boleh mengesyorkan loji kilang padi 60tpd yang sesuai untuk memenuhi keperluan anda.

Mesin Pilihan untuk Unit Kilang Padi Lengkap

Mesin loji pemprosesan kilang padi 60tpd mempunyai kolokasi yang berbeza untuk mencapai matlamat yang anda perlukan. Berdasarkan loji kilang padi 60tpd ini, kami juga mempunyai mesin lain untuk ditempatkan.

Penggilap Padi

Mesin ini digunakan untuk barisan pengeluaran kilang padi, berfungsi untuk menjadikan padi lebih putih dan licin.

Pengisih Warna

Penyusun warna boleh membezakan antara beras putih yang baik dan cendawan, beras hitam. Untuk nasi putih yang berkualiti, ia banyak membantu.

Mesin Pembungkus

Kerana matlamat akhir adalah nasi putih untuk dijual, pakej adalah langkah yang perlu. Mesin pembungkusan untuk kilang padi ini berkisar antara 5kg hingga 50kg. Oleh itu, ia sangat praktikal.

Daripada perkara di atas, kami dapati bahawa barisan pengeluaran kilang padi yang lengkap untuk dijual mempunyai kolokasi yang berbeza untuk memenuhi keperluan perniagaan anda.

Perkhidmatan Ditawarkan pada Mesin Pengisar Beras Gabungan

Untuk unit pengilangan padi, rangkaian perkhidmatan berikut boleh disediakan:

- Jualan peralatan dan penyesuaian: Menyediakan set lengkap peralatan kilang pemprosesan kilang padi dengan skala keluaran yang berbeza, seperti 15TPD unit kilang padi, 25TPD, dsb., dan boleh menyesuaikan mesin pengisar padi dengan spesifikasi dan konfigurasi khas mengikut keperluan anda.

- Perundingan teknikal dan reka bentuk: Mengikut keperluan khusus anda, ciri bahan mentah dan keadaan tapak, kami menyediakan reka bentuk barisan pengeluaran pengilangan padi profesional dan perkhidmatan perundingan teknikal.

- Sokongan dan penyelenggaraan selepas jualan: Pembaikan atau penggantian percuma bahagian yang rosak semasa tempoh jaminan peralatan; menyediakan sokongan teknikal tepat pada masanya dan perkhidmatan penyelenggaraan berbayar di luar tempoh jaminan.

- Bekalan alat ganti: Bekalan jangka panjang semua jenis alat ganti asal yang diperlukan oleh kilang pemprosesan kilang padi, untuk memastikan kualiti dan keserasian alat ganti yang diperlukan dalam proses penggunaan peralatan.

Mulakan Perniagaan Pengilangan Padi Sekarang!

Cepat hubungi kami, kami akan mereka padanan mesin yang munasabah untuk anda mengikut keperluan khusus anda, untuk memenuhi keperluan yang berbeza dalam menjalankan pengilangan padi.