የእንስሳት መኖ Pellet ምርት መስመር

የታይዚ የእንስሳት መኖ የእህል ምርት መስመር በቆሎ፣ ስንዴ፣ ባቄላ፣ ገለባ ወዘተ በመጠቀም ከ 2.5-8 ሚሜ የሆነ ዲያሜትር ያላቸውን የእንስሳት እና የዶሮ መኖ የእህል ምርቶችን ለመሥራት ያገለግላል። በሰዓት 500-2000 ኪሎ ግራም አቅም ያለው ሲሆን በተለይ ለመካከለኛ እና ትላልቅ የመኖ ወፍጮዎችና እርሻዎች ተስማሚ ነው።

ይህ የምግብ ፔሌት ተክል በከፍተኛ አውቶሜሽን, ዝቅተኛ የኃይል ፍጆታ እና ከፍተኛ የምርት ቅልጥፍና ተለይቶ ይታወቃል. ለምግብ እንክብሎችን ለመሥራት ውጤታማ እና ኢኮኖሚያዊ መፍትሄ ነው።

የእንስሳት መኖ እንክብሎችን በፍጥነት እና በብቃት ለመስራት ከፈለጉ ለተጨማሪ ዝርዝሮች እኛን ለማነጋገር እንኳን ደህና መጡ!

የእንስሳት መኖ እንክብሎች የምርት መስመር ጥቅሞች

- በሰዓት ከ500-2000 ኪ.ግ. የእኛ የምግብ ፔሌት ወፍጮ ባለ አራት-ሮለር መዋቅርን ከፍተኛ ምርት ይይዛል። የውጤቱ መጠን በሰዓት 500-2000 ኪ.ግ.

- አውቶማቲክ ከፍተኛ ደረጃ.

- ይህ መስመር አውቶማቲክ ባችንግ እና የመለኪያ ስርዓት የተገጠመለት ነው። የቀመርው ጥሬ እቃዎች በተቀመጠው መጠን መሰረት በራስ-ሰር ይመገባሉ.

- ከተመዘነ በኋላ ቁሱ በራስ-ሰር ይወጣል. የሚቀጥለው የክብደት እና የክብደት ስብስብ መፍሰሱ ከተጠናቀቀ በኋላ በራስ-ሰር ይጀምራል።

- የ1‰-3‰ የክብደት ትክክለኛነት. የጥሬ ዕቃዎች ብክነትን እና የተመጣጠነ ምግብን አለመመጣጠን በማስወገድ የጠቅላላው መስመር የክብደት ትክክለኛነት ከፍተኛ ነው።

- ማበጀት. እንደፍላጎትዎ የመስመሩን ውቅረት መሰብሰብ እና የማሽኑን ኃይል፣ ቮልቴጅ፣ ቀለም፣ ወዘተ ማበጀት እንችላለን።

የእንስሳት መኖ እንክብሎችን የማምረት ሂደት ምንድነው?

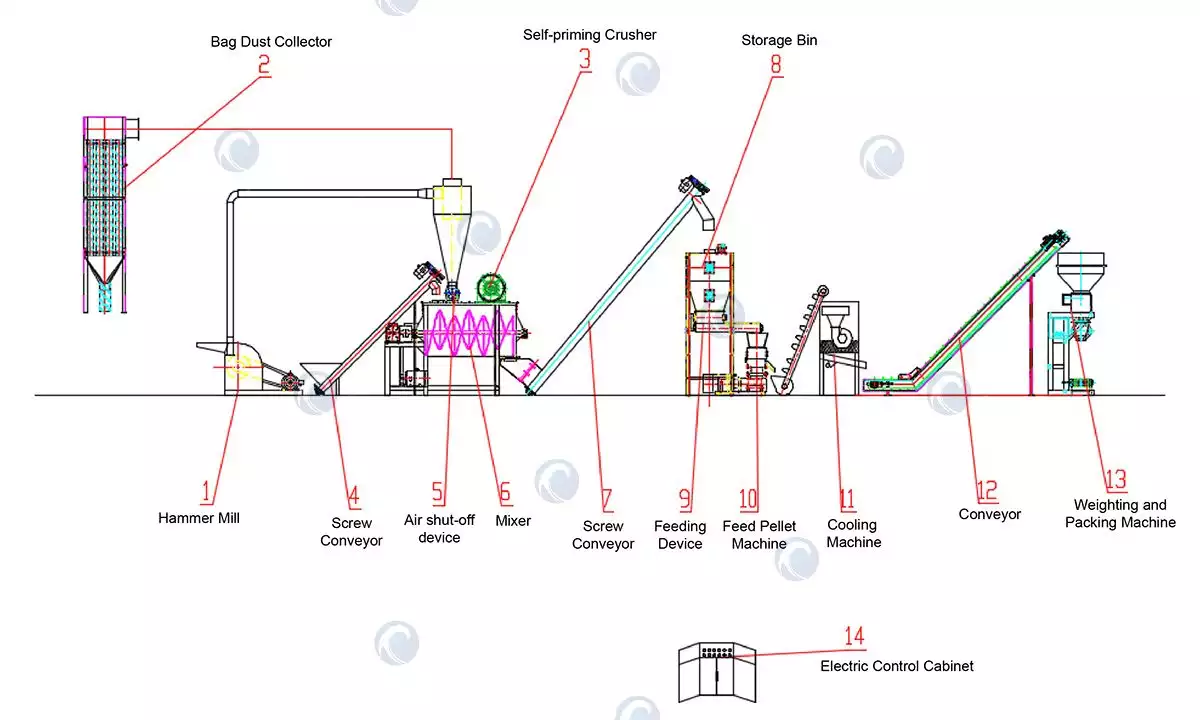

የእንስሳት መኖ የእህል ምርት መስመር ደረጃዎች መፍጨት→መቀላቀል→የእህል ማድረግ→ማቀዝቀዝ→ማሸግን ያካትታሉ። ጠቅላላው ሂደት በሚከተለው የፍሰት ገበታ ላይ ይታያል። ከዚህ በታች የእንስሳት መኖን የማምረት ጠቅላላ ሂደት እና በሂደቱ ውስጥ ጥቅም ላይ የሚውሉ መሳሪያዎችን በዝርዝር እናስተዋውቃለን።

ደረጃ 1: ጥሬ ዕቃዎችን ማዘጋጀት

በመጀመሪያ ጥሬ እቃዎችን ማዘጋጀት ያስፈልግዎታል. የመኖ እንክብሎች ጥሬ ዕቃዎች በተከማቸ መኖ እና በሣር መኖ የተከፋፈሉ ናቸው፡

- የተጠናከረ ምግብ: በቆሎ, አኩሪ አተር, ስንዴ, የስንዴ ብሬን እና ሌሎች ጥራጥሬዎች.

- የሳር ምግብ: ገለባ, የኦቾሎኒ ችግኞች, የስንዴ ገለባ, የእንስሳት እርባታ ሣር, የአልፋልፋ ሣር እና ሌሎች የሳር ዱቄት.

ትልቅ አቅም ላለው የእንስሳት መኖ (እንደ 1-2t/ሰ) ከሆነ ጥሬ እቃ ማጓጓዣ፣ የመጠን መለኪያ እና አውቶማቲክ የፍሳሽ ማስወገጃ ቫልቭ እናሟላለን።

ደረጃ 2፡ መፍጨት

ከዚያም ጥሬ እቃዎቹ መፍጨት አለባቸው. ሁለት አይነት ክሬሸሮች አሉን ፣መዶሻ ወፍጮ እና ቢላዋ ሳህን መፍጫ።

- 9FQ መዶሻ ወፍጮ

- ለአቧራ መሰብሰብ አውሎ ነፋሱን ይጠቀሙ።

- ጥሬ ዕቃዎችን ለመመገብ ከስክሩ መጋቢ ጋር ይስሩ።

- ቢላዋ መፍጫ

- ከ9FQ ጋር ሲነጻጸር፣ ተጨማሪ መግቢያ አለ።

- ተግባሩ መጀመሪያ ምዝግቦቹን መቁረጥ እና ከዚያም መፍጨት ነው.

- ለሲሊንደሪክ ጥሬ ዕቃዎች ተስማሚ ነው, ለስላሳ ጥሬ ዕቃዎች ተስማሚ አይደለም.

ሁለቱም የሚከተሉት ክፍሎች አሏቸው።

- ስክሪኖችመጠኖች 3 ሚሜ ፣ 4 ሚሜ ፣ 5 ሚሜ ፣ 6 ሚሜ እና 8 ሚሜ

- መዶሻዎችከማንጋኒዝ ብረት የተሰራ

- ቢላዎች: ከተንግስተን ጋር

የአገልግሎት ህይወት በአጠቃላይ 500 ሰዓታት ነው. የመተኪያ ጊዜው እንደ ቁሳቁስ እና የአጠቃቀም ድግግሞሽ ይለያያል. ከግማሽ ዓመት በኋላ አንድ ስብስብ መተካት ያስፈልግዎታል.

ደረጃ 3: መቀላቀል

በመቀጠልም የተጨመቁትን ጥሬ እቃዎች ለመደባለቅ ማቀፊያውን መጠቀም አለብዎት. እንደቅደም ተከተላቸው ቀጥ ያለ ቀላቃይ እና አግድም ቀላቃይ 2 አይነት ቀላቃይ አሉን።

- አቀባዊ ቀላቃይ

- ለጥራጥሬዎች ብቻ ተስማሚ ነው, ወይም አነስተኛ መጠን ያለው የሳር ዱቄት የያዙ ጥሬ ዕቃዎች.

- በአጠቃላይ ለዶሮ መኖ እና ለአሳማ መኖ ለማምረት ያገለግላል.

- አግድም ቀላቃይ

- ከ 20% በላይ የሳር ዱቄት እና እርጥበት ከ 20% በላይ የሆኑ ጥሬ እቃዎች.

- አግድም ቀላቃይ ራሱ ይበልጥ በእኩል ይቀላቀላል.

- ለበግ መኖ እና ለከብት መኖ ለማምረት ያገለግላል።

ደረጃ 4፡ መበጠር

ይህ ለመላው የእንስሳት መኖ የእህል ምርት መስመር በጣም አስፈላጊው እርምጃ ነው። የእኛ የመኖ የእህል ማሽን የተለያዩ አይነቶች አሉት። እንደ ፍላጎቶችዎ ተስማሚ የሆነውን መምረጥ ይችላሉ።

- የኃይል ስርዓትየኤሌክትሪክ ሞተር፣ የናፍታ ሞተር እና የ PTO ዓይነት

- አቅም: 500-1200kg/ሰ(ትልቅ አቅም ካለው 2 ወይም ከዚያ በላይ የእንስሳት መኖ እንክብሎችን ተጠቀም)

- ጥቅሞች: ወጪ ቆጣቢነት, ሰፊ አማራጮች እና ከፍተኛ ምርታማነት

ደረጃ 5: ማቀዝቀዝ

ከተጣራ በኋላ የእንስሳት መኖ እንክብሎች የተወሰነ ሙቀት አላቸው እና አሁን ማቀዝቀዣ ማሽኖች ያስፈልግዎታል. አግድም ማቀዝቀዣ እና ባልዲ ማቀዝቀዣ አለን.

- የማሽን ስም: ቀዝቃዛ

- ተግባር: ማቀዝቀዝ እና መለያየት

- የማቀዝቀዣ ሙቀትከክፍል ሙቀት ከ3-5 ዲግሪ ከፍ ያለ

- ጥቅሞች: አነስተኛ መጠን, ዝቅተኛ አቧራ, ለማጓጓዝ ቀላል እና ለመሥራት ቀላል

- መዋቅር: ዋና ማሽን እና ደጋፊዎች

- ዓይነቶች: አግድም ማቀዝቀዣ እና ባከር ማቀዝቀዣ

- አግድም ማቀዝቀዣ

- 50 ዓይነት: ለፔሌት ፋብሪካዎች ሞዴል 300 እና ከዚያ በታች ተስማሚ እና ከ 800 ኪሎ ግራም በታች የሆኑ ሞዴሎች. አንድ የደጋፊዎች ስብስብ በቂ ነው።

- 70 ዓይነት: ለ 300 እና 400 ሞዴል የፔሌት ማሽኖች ተስማሚ እና ከ 800 ኪ.ግ በላይ ምርት ያላቸው ሞዴሎች. ሁለት የአድናቂዎች ስብስቦች መታጠቅ አለባቸው.

- ባልዲ ማቀዝቀዣ

- የእንስሳት መኖ እንክብሎችን ለማቀዝቀዝ ያገለግላል.

- አግድም ማቀዝቀዣ

ደረጃ 6: ማሸግ

በመጨረሻም ለምግብ እንክብሎች ቦርሳ ማሸጊያ ማሽኑን መጠቀም አለቦት።

- ማሸጊያ ማሽን

- አካላት: ክፍልን መመዘን ፣ ማጓጓዣ ክፍል ፣ የማሸጊያ ክፍል እና የማሰብ ችሎታ ያለው ክፍል

- የክብደት ክልል: 10-50kg / ቦርሳ

- የማተም ዘዴ: የሽቦ ማኅተም ማሸጊያ, እና የሙቀት ማኅተም ማሸግ

የዶሮ መኖ ምርት መስመር ዋጋስ?

የእንስሳት መኖ የፔሌት ማምረቻ መስመር ዋጋ እንደ ልዩ ውቅር እና አቅም ይለያያል። የማዋቀሩ እና የማምረት አቅሙ ከፍ ባለ መጠን በጣም ውድ ነው.

ዋጋዎች በብዙ ምክንያቶች ተጽዕኖ ስለሚኖራቸው ከአምራቹ ጋር በቀጥታ ለመገናኘት ይመከራል. የተወሰኑ የምርት መስፈርቶችን እና የበጀት ክልልን ማቅረብ ይችላሉ, እና በጣም ትክክለኛውን ጥቅስ እናቀርባለን.

የእንስሳት መኖ ፔሌት ማቀነባበሪያ ማሽን መስመርን ለመምረጥ ምክሮች

የእንስሳት መኖ የፔሌት ማምረቻ መስመርን በሚመርጡበት ጊዜ የሚከተሉትን ምክንያቶች ግምት ውስጥ ማስገባት አለብዎት.

- የመሳሪያዎች አፈፃፀም

- ከፍተኛ ቅልጥፍናየምርት ቅልጥፍናን እና ምርትን ለማረጋገጥ የእንስሳት መኖ ፔሌት ማሽንን በከፍተኛ ብቃት ይምረጡ።

- መረጋጋትመስመሩ በተረጋጋ ሁኔታ መሮጥ፣ የውድቀቱን መጠን መቀነስ እና የምርት ቀጣይነቱን ማረጋገጥ አለበት።

- የማምረት አቅም

- የአቅም ማዛመድበእራስዎ የምርት መጠን መሰረት ተገቢውን የአቅም መጠን ይምረጡ.

- ተለዋዋጭነትየምርት መስመሩን መስፋፋት እና ተለዋዋጭነት ግምት ውስጥ ያስገቡ። ለወደፊቱ የምርት ልኬቱን ማስተካከል ከፈለጉ ይህ ምቹ ይሆናል.

- ራስ-ሰር ደረጃ

- አውቶማቲክ ዲግሪየምርት ቅልጥፍናን ለማሻሻል እና የሰው ኃይል ወጪዎችን ለመቀነስ ለምርት መስመሮች በከፍተኛ አውቶሜሽን ቅድሚያ ይስጡ.

- ብልህ ቁጥጥርየማሰብ ችሎታ ካለው የቁጥጥር ስርዓት ጋር, የምርት ሂደቱን ለመሥራት እና ለመቆጣጠር ቀላል ነው.

- የክትትል አገልግሎት

- የቴክኒክ ድጋፍ: የመሳሪያውን መደበኛ አሠራር እና ጥገና ለማረጋገጥ ሁሉን አቀፍ የቴክኒክ ድጋፍ የሚሰጠውን አምራች ይምረጡ.

- ከሽያጭ በኋላ አገልግሎትከሽያጭ በኋላ ያለውን አገልግሎት ግምት ውስጥ ያስገቡ። ችግሮችን በወቅቱ እና ውጤታማ በሆነ መንገድ መፍታት እንደሚቻል ያረጋግጡ።

- የኃይል ፍጆታ እና የአካባቢ ጥበቃ

- ኃይል ቆጣቢ ንድፍዝቅተኛ የኃይል ፍጆታ እና ከአካባቢያዊ ደረጃዎች ጋር በተጣጣመ የእንስሳት መኖ ፔሌት ማሽን መስመሮችን ይመርጣሉ. የዘላቂ ልማት መስፈርቶችን በሚያሟሉበት ጊዜ የሥራ ማስኬጃ ወጪዎችን ይቀንሳል።

- ወጪ ቆጣቢነት

- ወጪ ቆጣቢነት: የመሳሪያውን ዋጋ እና አፈፃፀም ግምት ውስጥ ያስገቡ እና የእንስሳት መኖ የፔሌት ማምረቻ መስመርን በከፍተኛ ወጪ ቆጣቢነት ይምረጡ።

- ወደ ኢንቨስትመንት መመለስምክንያታዊ ኢኮኖሚያዊ ጥቅሞችን ለማረጋገጥ የምግብ ፔሌት መስመርን የኢንቨስትመንት ዑደት መገምገም.

የእንስሳት መኖ የፔሌት ማምረቻ መስመር የት ነው የሚገዛው?

የእንስሳት መኖ የፔሌት ማሽን መስመሮችን መግዛት ከፈለጉ, ምንጮቹ እንደሚከተለው ናቸው.

- የባለሙያ ገበያ

- የፋብሪካ ጉብኝትወደ ፕሮፌሽናል የግብርና ማሽነሪ ፋብሪካ ይሂዱ እና የተለያዩ የምርት ስሞችን እና ሞዴሎችን ያወዳድሩ።

- ፊት ለፊት መገናኘትከሽያጭ ሰራተኞች ጋር ፊት ለፊት መገናኘት, የመሣሪያዎች አፈፃፀም እና ዋጋ ዝርዝር ግንዛቤ.

- የበይነመረብ መድረክ

- የመስመር ላይ ፍለጋእንደ ጎግል ባሉ የፍለጋ ሞተሮች የአቅራቢ መረጃ ያግኙ።

- የመስመር ላይ ምክክር: አቅራቢዎችን ለማግኘት እና ዝርዝር መረጃ እና ጥቅሶችን ለማግኘት የመስመር ላይ የውይይት መሳሪያ (እንደ WhatsApp) ይጠቀሙ።

- ግምገማን ይፈትሹየአቅራቢውን መልካም ስም እና የአገልግሎት ጥራት ለመገምገም የሌሎች ተጠቃሚዎችን ግምገማ እና አስተያየት ይመልከቱ።

በላይ ባሉ ቻናሎች አማካኝነት ፍላጎቶችዎን የሚያሟላ የእንስሳት መኖ የእህል ምርት መስመር ማግኘት ይችላሉ። ስለ የእንስሳት መኖ አሰራር አሁንም ጥያቄዎች ካሉዎት፣ ለተጨማሪ መረጃ እኛን ያነጋግሩን!