کمباین برنج برای برنج شالیزاری گندم با خرمنکوب

این کمباین برنج (که به آن کمباین گندم، کمباین کوچک نیز گفته می شود) یک تجهیزات کشاورزی چند منظوره است که نه تنها محصولات برنج و گندم را به طور موثر درو می کند، بلکه دارای عملکرد خرمن کوبی است که با استفاده از خرمن کوب داخلی، دانه ها را از پوسته جدا می کند. این دستگاه با قابلیت تنظیم انعطاف پذیر خود که به آن اجازه می دهد با درو در شرایط تپه ای سازگار شود، بهره وری کشاورزی را بهبود می بخشد. علاوه بر این کمباین کوچک، ما همچنین دستگاه خرمن کوب برای گندم و برنج داریم. در صورت علاقه، برای جزئیات بیشتر با ما تماس بگیرید!

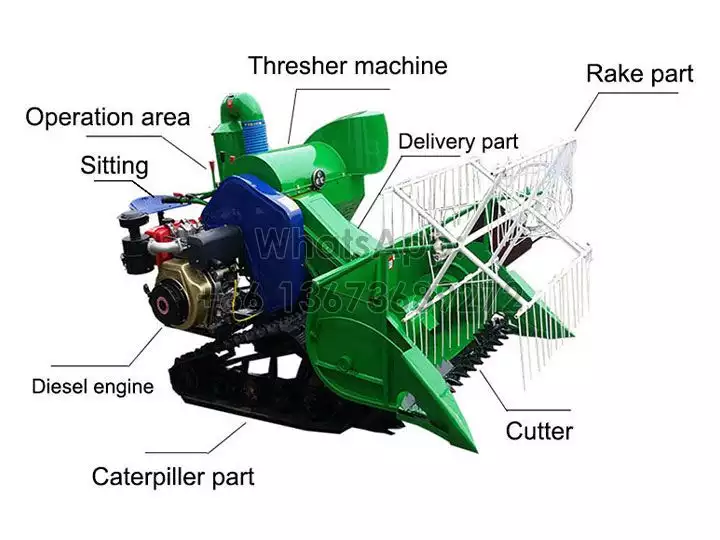

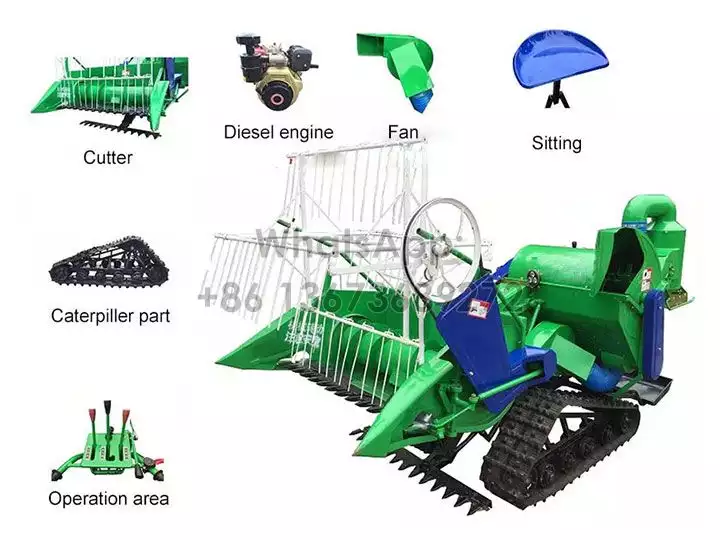

آیا از قطعات و عملکرد کمباین برنج اطلاع دارید؟

| قطعات ماشین آلات | تابع |

| سیستم قدرت | مطابق با موتور دیزل مارک جهانی قدرت بالا، قدرت قوی راندمان بالا در برداشت، خرمن کوبی و مسافرت |

| سیستم سفر | مسیرهای طولانی تر و عریض تر، اثر ضد به دام افتادن/ضد لغزش برجسته تر مجهز به چراغ جلو LED فوق العاده روشن برای برداشت در شب ضد آب و ضد شن، بادوام |

| سیستم نقاله | درام تغذیه بالاتر برای کاهش ریزش میز برش 8 سانتی متر پایین تر برای برداشت آسان برنج کوتوله و گندم تغذیه و انتقال ساختار، اجتناب از تف کردن پشت و انتقال مربا |

| سیستم خرمنکوبی | درام خرمنکوب طراحی تدریجی، بدون گیر کردن و راندمان کوبیدن بالاتر را اتخاذ می کند طراحی دهانه تخلیه نی عالی، تخلیه نی صاف تر طراحی صفحه نمایش با فرمت فارغ التحصیل، کاهش ریختن، کاهش نرخ ناخالصی |

| سیستم عامل | طراحی منحصر به فرد، ساختار ساده، عملیات ایمن تر ساختار چند سرعته، کارکرد آسان تر اثر پارکینگ در شیب تند بهتر است، بدون لغزش هنگام بالا رفتن از شیب ها |

مشخصات کمباین برنج

به عنوان یک تولید کننده حرفه ای تجهیزات کشاورزی، مینی کمباین ما برای برنج گندم با توجه به مسیرهای مختلف به مدل های مختلفی تقسیم می شود، اما همه آنها را می توان برای برداشت و خرمنکوبی برنج و گندم استفاده کرد، در زیر پارامترهای خاص برای شما آورده شده است. مرجع.

| مدل | 4LZ-1.05C | 4LZ-1.05D |

| نوع خزنده | خزنده تخت | خزنده مثلثی |

| عرض برش | 1100 میلی متر | 1100 میلی متر |

| حداقل فاصله از زمین | 190 میلی متر | 190 میلی متر |

| فشار متوسط زمین | 10.9KPA | 10.9KPA |

| حجم تغذیه | 1.05 کیلوگرم بر ثانیه | 1.05 کیلوگرم بر ثانیه |

| اندازه | 3100*1440*1630 میلی متر | 3100*1440*1630 میلی متر |

| وزن | 570 کیلوگرم | 570 کیلوگرم |

| مدل موتور | KD1100FB دیزل | KD1100FB دیزل |

| روش شروع | استارت برقی | استارت برقی |

ویژگی های کمباین کوچک برای گندم برنج

- طراحی فشرده: به دلیل کمباین کوچک، این کمباین گندم با زمین های زراعی محدود سازگار می شود. ساختار نسبتا سبک وزن آن استفاده از آن را در زمین های محدود آسان می کند.

- تطبیق پذیری: این مینی کمباین برنج چند کاره است و می توان از آن برای برداشت برنج و گندم استفاده کرد و باعث افزایش استفاده از دستگاه می شود.

- قابلیت کارآمد: کمباین برنج کوچک با وجود اندازه کوچکش معمولا کارایی بالایی دارد. می تواند برداشت را در یک دوره نسبتاً کوتاه کامل کند و بهره وری را افزایش دهد.

- کارکرد آسان: دستگاه کمباین کوچک گندم اغلب به گونه ای طراحی می شود که برای کشاورزانی که مهارت های تخصصی ندارند کار با آن آسان باشد. کنترل های ساده و سیستم عامل ها بار کاربر را کاهش می دهد.

- قابل تطبیق: کمباین ها به دلیل سبکی و تحرک نسبی خود در انواع مختلف خاک و زمین عملکرد خوبی دارند و انعطاف پذیری کاربرد آنها را افزایش می دهند.

- مقرون به صرفه: در مقایسه با کمباین های بزرگتر، این دستگاه کمباین برنج معمولاً مقرون به صرفه تر است. این باعث می شود که تجهیزات در دسترس کشاورزان بیشتر شود و سطح فناوری مزارع کوچک بهبود یابد.

- هزینه نگهداری کم: مینی کمباین برنج گندم به دلیل ساختار مکانیکی نسبتاً ساده ای که دارد معمولاً هزینه نگهداری پایینی دارد و از بار کشاورزان می کاهد.

چگونه برنج گندم را با کمباین کوچک برداشت کنیم؟

کمباین گندم برنج را شروع کنید

اپراتور کمباین کوچک برای برنج را راه اندازی می کند و اطمینان حاصل می کند که همه سیستم ها به درستی کار می کنند. این شامل موتور، سیستم برش، تسمه نقاله و غیره است.

مینی کمباین برنج را به مزرعه ای که قرار است برداشت شود هدایت کنید. در طول حرکت، اپراتور باید مراقب باشد تا از موانع جلوگیری کند و اطمینان حاصل کند که دستگاه به خوبی کار می کند.

برداشت را شروع کنید

هنگامی که دستگاه به موقعیت مناسب رسید، اپراتور شروع به برداشت می کند. دستگاه کمباین گندم معمولاً با حرکت دادن سر برش به صورت جانبی و انتقال آنها به داخل دستگاه برای پردازش بیشتر، گیاهان را برداشت می کند.

کوبیدن و تمیز کردن

در داخل دستگاه، گندم یا برنج از طریق سیستم خرمن کوبی عبور می کند که دانه را از گیاه جدا می کند. کاه و علف های هرز باقی مانده معمولاً از طریق سیستم تمیز کننده تخلیه می شوند.

جمع آوری و ذخیره سازی

دانه های کوبیده شده را جمع آوری کرده و در گونی های از پیش آماده شده نگهداری می کنند. در صورت پر شدن، دانه ها را می توان برای انتقال به انبارها یا وسایل نقلیه حمل و نقل تخلیه کرد.

نظارت و تنظیم

اپراتور باید به طور مداوم بر عملکرد دستگاه نظارت داشته باشد و تنظیمات لازم را برای اطمینان از یک فرآیند برداشت کارآمد انجام دهد.

پایان برداشت

هنگامی که مزرعه به طور کامل برداشت شد، اپراتور دستگاه را برای انجام کارهای تمیزکاری و نگهداری نهایی متوقف می کند.

قیمت کمباین برنج چطور؟

قیمت کمباین گندم برنج تحت تأثیر برند، مدل، عملکرد، پیکربندی و منطقه بازار است. به طور کلی، ماشینهای کمباین برنج بزرگتر و پیشرفتهتر نسبتاً گران هستند، در حالی که مدلهای کوچکتر یا اولیه اقتصادیتر هستند. به طور مشابه، ماشین های تضمین شده با کیفیت معمولاً هزینه بیشتری دارند.

به عنوان مثال، دستگاه کمباین برنج کوچک ما برای پیکربندی های مختلف از یک مدل قیمت متفاوتی دارد. قیمت نیز به دلیل تفاوت در مسیرها، یک خزنده صاف و یک خزنده مثلثی متفاوت است. بنابراین برای دریافت قیمت دقیق کمباین برنج، مستقیماً با ما تماس بگیرید تا قیمت دقیق را ارائه دهیم و مدل های موجود و ویژگی های آنها را درک کنیم.

تولید کننده و تامین کننده معتبر کمباین برنج مینی

ما یک تولید کننده و تامین کننده معتبر کمباین برنج کوچک هستیم که به ارائه راه حل های کشاورزی قابل اعتماد به شما اختصاص دارد. محصولات ما که به خاطر راندمان بالا، بهره وری انرژی و دوام خود شناخته شده اند، به دقت طراحی شده اند تا با طیف وسیعی از شرایط کشاورزی مطابقت داشته باشند. علاوه بر آن، ما بر کیفیت محصولات خود تمرکز می کنیم و از فناوری پیشرفته و مواد با کیفیت برای اطمینان از عملکرد برتر و عمر طولانی ماشین های خود استفاده می کنیم.

همچنین، ما خدمات پس از فروش جامع را ارائه می دهیم. تیم خدمات ما متشکل از تکنسین های مجرب است که همیشه آماده پشتیبانی از شما و حل مشکلات هستند. ما خدمات تعمیر و نگهداری منظم را ارائه می دهیم تا اطمینان حاصل شود که ماشین ها برای مدت طولانی پایدار کار می کنند. برای نیازها و مشکلات مشتریان، ما پاسخ و راه حل های به موقع می گیریم و متعهد به ارائه بهترین تجربه به مشتریان هستیم.

فروش بسته بندی و تحویل دستگاه کمباین برنج

پس از اینکه مشتری با ما همکاری کرد، ما یک سری اقدامات را انجام می دهیم تا اطمینان حاصل کنیم که کمباین برنج در حین حمل و نقل ایمن و بدون آسیب است. بسته به نیاز مشتری می توانیم دستگاه را در جعبه چوبی بسته بندی کنیم یا مستقیماً آن را ارسال کنیم.

بسته بندی جعبه چوبی: تیم ما با دقت بسته بندی می کند تا اطمینان حاصل شود که هر قسمت حیاتی به درستی محافظت می شود. برای جعبه های چوبی، تیم ما با دقت بسته بندی می کند و اطمینان حاصل می کند که هر قسمت حیاتی به درستی محافظت می شود. ما برچسب های واضح را علامت گذاری می کنیم و اسناد لازم را برای اطمینان از روند ترخیص گمرکی روان آماده می کنیم.

تحویل: نحوه حمل و نقل با توجه به نیاز مشتری، از جمله حمل و نقل زمینی، دریایی یا هوایی ترتیب داده می شود. ما اطلاعات ردیابی حمل و نقل را ارائه می دهیم تا اطمینان حاصل شود که مشتری از موقعیت و زمان ورود دستگاه مطلع است.

هدف ما ارائه خدمات بسته بندی و حمل و نقل ایمن و کارآمد است تا اطمینان حاصل شود که مشتریان ما کمباین برنج با کیفیت را دریافت می کنند.

نکاتی برای انتخاب کمباین شلتوک

بر اساس شرایط و نیازهای واقعی مزرعه، کمباین شالیزاری مناسب را با دقت انتخاب کنید. برای اطمینان از اینکه کمباین برنج در شرایط مختلف عملکرد خوبی خواهد داشت، باید محیطی را که در آن برنج در آن کشت می شود در نظر بگیرید. در اینجا چند پیشنهاد وجود دارد که باید بر اساس ویژگی های مختلف خزنده های ماشینی ما در نظر بگیرید:

اگر زمین های شما عمدتاً خشک و گل آلود نیستند، نوع خزنده مثلثی ممکن است انتخاب خوبی باشد زیرا پایداری بهتری را ارائه می دهد.

در مناطق گل آلود یا عمیق با پای گلی، نوع مسیر مسطح مناسب تر است زیرا تأثیر خوبی بر خاک را کاهش می دهد و خطر دستگاه شما را کاهش می دهد.

مراحل سفارش دستگاه کمباین

- برای استعلام قیمت با ما تماس بگیرید: ابتدا باید با ما تماس بگیرید تا نیازهای خود را به ما بگویید و ما یک مدیر حرفه ای برای ارائه اطلاعات دقیق به شما اختصاص می دهیم.

- دستگاه را با جزئیات بشناسید: در حین گفتگو با مدیر حرفه ای، به تدریج با دستگاه کمباین برنج بیشتر آشنا می شوید و به نیازهای خود آگاهی پیدا می کنید.

- دستگاه را تعیین کنید: با توجه به موارد فوق، می توانید به وضوح نوع ماشین مورد نظر، جزئیات دستگاه و غیره را به ما بگویید.

- قرارداد را امضا کنید و سپرده را پرداخت کنید: پس از تصمیم گیری برای ثبت سفارش، ما هر دو قرارداد را امضا می کنیم و شما باید پیش پرداخت را پرداخت کنید (معمولاً 30%).

- تولید ماشین: پس از دریافت سپرده، کارخانه ما شروع به تولید دستگاه می کند و ما شما را در جریان پیشرفت تولید دستگاه قرار می دهیم.

- تایید تکمیل ماشین و پرداخت نهایی: هنگام تکمیل دستگاه مینی کمباین برنج، عکس و تاییدیه ویدیویی را به شما می دهیم و باید موجودی را پرداخت کنید و سپس دستگاه را برای تحویل جعبه کنید.

- بسته بندی و ارسال: ماشین ها معمولاً بسته بندی شده و از طریق دریا به مقصد شما ارسال می شوند (در موارد خاص می توان این کار را بین دو طرف هماهنگ کرد).