Proyek tender Maroko: 74 set penggilingan palu 9FQ & 4 set pelletizer

This Moroccan client, acting as the procurement entity for a local government/institutional tender project, required bulk purchases of 9FQ hammer mills and feed pelletizers for centralized deployment and long-term operation.

The client imposed stringent requirements on equipment consistency, configuration standards, motor specifications, and safety, explicitly stating: “Equipment matches the sample drawings exactly; no deviations permitted.”

Client’s core focus areas

During negotiations, the client emphasized the following key points:

- Ability to deliver large volumes with consistent quality

- Complete uniformity in machine structure, appearance, thickness, and internal configuration

- Whether motors are pure copper core motors meeting national standards

- Compliance with European voltage, plug, and safety requirements

- Ability to verify and confirm each item against the tender documents

Our solution: 9FQ-320 hammer mill and feed pelletizer

For the tender requirements, we customized both machines entirely:

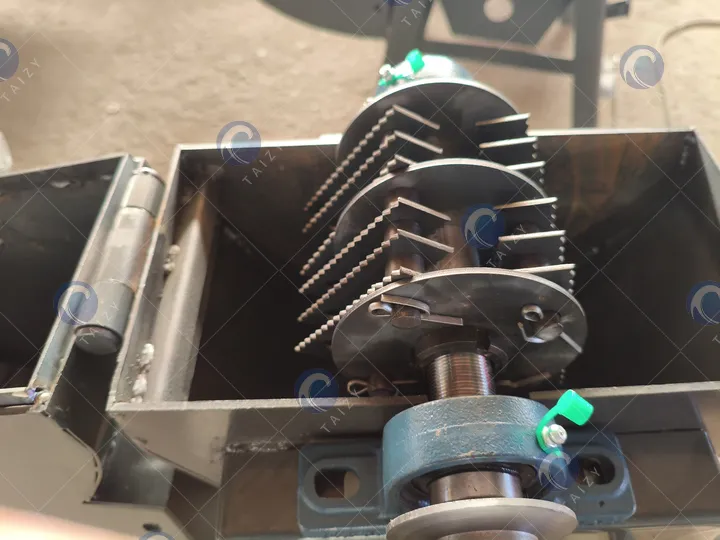

9FQ hammer mill configuration

- Model: 9FQ-320

- Output: 100–200 kg/h

- Motor: 2.2 kW (GB standard pure copper core, nameplate marked 3 kW)

- Voltage: 220V / 50Hz / Single-phase

Structure:

- Internal 24 hammer plates

- Body thickness 3mm

- Belt drive + protective cover

- Configured screens: 1.5mm / 3mm / 8mm

- Color: Gray

Additional requirements:

- Extra 2.5-meter power cord

- European standard plug

In accordance with the aforementioned standards, a total of 74 sets of 9FQ-320 hammer mill pulverizers were delivered.

Pelletizer configuration

To process pulverized materials into pellets, the customer also procured a feed pelletizer.

SL-120B pelletizer specifications:

- Power: 3 kW motor

- Output: 60–100 kg/h

- Voltage: 220V / 50Hz / Single-phase

- Die: 4mm disc

Pre-shipment requirement: The motor nameplate must be photographed for verification. A total of 4 pelletizers were delivered this time.

Production & quality control of 9FQ hammer mill and feed pelletizer

For this tender project, we implemented:

- Production strictly matching drawings and prototype units

- Pre-shipment inspection of appearance, configuration, and motor nameplates for each unit

- Photo verification of motors, voltages, and plugs for every unit

- Batch numbering for streamlined customer acceptance and management

Packaging & shipping

All equipment features:

- Reinforced packaging for impact and moisture protection

- Bulk container loading with clear inventory lists

- Compliance with long-distance ocean shipping and project delivery requirements

All these ensure safe arrival and seamless delivery of equipment during transit

Why do tender clients choose us?

The core reasons our Moroccan client ultimately selected us for their one-time purchase of 78 units include:

✅ Support for stringent tender standards and custom requirements

✅ Stable large-volume supply capability

✅ Transparent configurations and authentic specifications

✅ Competitive pricing with high cost-performance ratio

✅ Experience with African markets and tender project procedures

Looking for a tender supplier for crushers, pellet mills or other agricultural machinery?

Contact us to receive technical specifications, quotation proposals, and successful project references. We provide comprehensive solutions tailored for tenders and bulk procurement.