15TPD Rysmeul Plant

Taizy se 15TPD-rysmeulplant is klein-skaalse rysmeultoerusting wat rou rys in gemaalde wit rys verander. Dit het 'n kapasiteit van 15 ton rys daagliks (600-700 kg per uur) en is geskik vir begin- en klein & medium-grootte rysverwerkingsaanlegte.

Dit is volledig outomaties, en voltooi die prosesse van die bestemming, skuil, skeiding, frees en sifting. Hierdie rysmeule -plant het 'n redelike struktuur, supergehalte en hoë werkdoeltreffendheid. Ons is na Ghana, die VSA, Nigerië, Kenia, Peru, Burkina Faso, Cote d’Ivoire en ander lande uitgevoer.

As u belangstel in hierdie rysfrees -eenheid, kontak ons dan, en ons bied oplossings aan u op grond van u werklike eise.

15TPD rysmeule plantproduksieproses

Soos hierbo genoem, is die basiese stappe vir hierdie basiese weergawe van die rysmeul-eenheid ontsteen → rysdop → rys en bruinrys skei → rysmeul → wit rys sif. Elke stap en die toerusting wat in daardie stap gebruik word, sal hieronder in detail beskryf word.

Ontsteenmasjien

Hierdie masjien verwyder hoofsaaklik die klip, groot grond, 'n bietjie groter strooi as paddy -rys, en klein sand of stof in die paddy -rys.

- Model: ZQS50

- Krag: 0,75+0,75 kW

Rysdopmasjien (6-duim rubberrol)

Dit verwyder die buitenste skil om bruinrys te kry.

- Model: LG15

- Krag: 4kw

Swaartekragskeier vir rys

Die masjien skei die bruinrys van padie deur die verskil van swaartekrag en wrywing op die oppervlak.

- Model: MGC270*5

- Krag: 0.75kw

Rysmeulmasjien (emeryrol)

Ons masjien reom die bruin velle om witrys te kry.

- Model: NS150

- Krag: 15kw

Rysgrader

Dit skei die hele rys en gebreekte rys op die skerm.

- Model: 40

- Krag: 0,55 kW

Tydens hierdie rysfreesproses is twee hysbakke nodig. Die hysbakke word gebruik as die onderstaande foto.

| Item | Model | Krag (kw) | Funksie |

| Hysbak 1 | TDTG18/07 | 0.75 | Dra die paddy -rys in Paddy Rice Destoner |

| Hysbak 2 | TDTG18/07*2 | 0.75*2 | Kanaal 1: Dra die skoon padie -rys aan Paddy Rice Husker. Kanaal 2: herwin bruinrys en paddy -rysmengsel terug na die swaartekrag -skewer. |

Tegniese parameters van 15TPD mini -rysmeuleplant

Uit die onderstaande tabel weet u dat die model van hierdie basiese weergawe gekombineerde rysmeule MCTP15 is. Die kapasiteit is 15ton/dag, en die gewig is 1400 kg. U kan ook weet wat die totale grootte en verpakkingsvolume is. Welkom om ons te kontak vir meer besonderhede!

| Model | Totale krag | Kapasiteit | Algehele grootte | Gewig | Verpakking volume |

| MCTP15 | 23.3kw | 15ton/dag (600-800 kg/h) | 3000*3000*3000mm | 1400kg | 8.5 cbm |

Voordele van 15TPD outomatiese rysmeuleplant

- Dit het 'n verwerking uitset van 600-800 kg per uur, wat aan die produksievraag van klein en mediumgrootte verwerkingsaanlegte voldoen.

- Die Maalsnelheid bereik 68-72%, wat die produksie van voltooide rys effektief verbeter en die verlies verminder.

- Die Gebreekte rystempo word binne 2% beheer, wat die kwaliteit van rys verseker en die mededingendheid van die mark verhoog.

- Hierdie rysfreesmasjienplant Gebruik altesaam 23,3 kW krag, minder kragverbruik.

- Ons hele stel toerusting Integreer die funksies van de-staling, romp, skeiding, rysfrees, gradering, ens., wat die handbediening verminder en die produksiedoeltreffendheid verbeter.

- Dit het 'n Klein voetspoor, en a Redelike uitleg, geskik vir verskillende groottes rysfrees en verwerkingsplante.

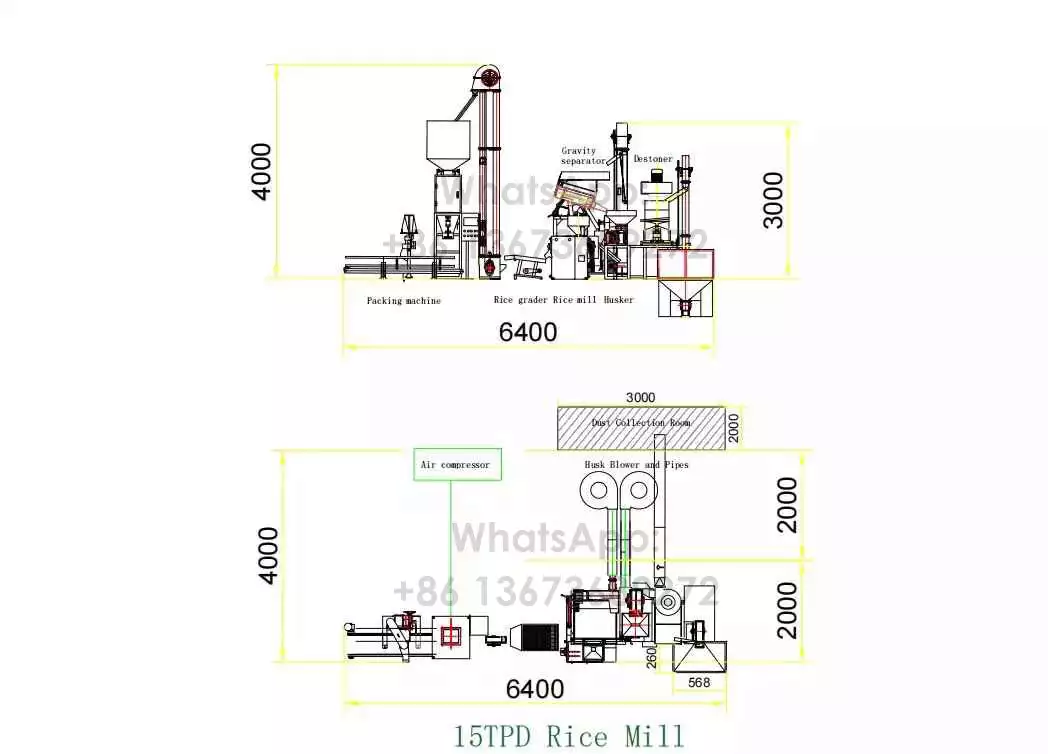

Rysmeule -plantuitlegontwerp

Redelike uitlegontwerp van rysmeule -eenhede is van kardinale belang om die produksiedoeltreffendheid te verbeter en energieverbruik te verminder. Hierdie moderne rysfreesaanleg bevat gewoonlik die opbergarea van die grondstowwe, die skoonmaak- en ontstekingsarea, romparea, rysfreesarea en graderingsarea. U kan ook die kleursorteerarea en die verpakkingsarea vir die finale produk voorberei.

'N Wetenskaplike uitleg kan die produksieproses optimaliseer en die doeltreffendheid verbeter, terwyl die toerusting glad is en die koste van die handbediening verminder. Ons kan die rysfreesplantuitleg bied vir u gerieflike gebruike en daaropvolgende uitbreidende onderneming.

Wat is die prys van die rysmeule?

Die prys van 'n 15TPD -rysmeule -masjienaanleg hang af van die kapasiteit, konfigurasie, outomatisering en ekstra funksies van die toerusting. Byvoorbeeld, 'n klein rysfrees-eenheid het 'n laer prys en is geskik vir kleinskaalse verwerkingsaanlegte, terwyl 'n volledig outomatiese produksielyn van die rysfrees 'n hoër prys het, maar 'n hoër produksiedoeltreffendheid het en geskik is vir grootskaalse verwerkingsaanlegte.

Die spesifieke kwotasie moet volgens die behoeftes van die kliënt aangepas word en gekombineer word met vervoer, installasie en ander koste vir 'n omvattende berekening.

Waarom kies Taizy as 15TPD Basci Rice Mill -plantverskaffer?

Taizy het uitgebreide ervaring in die rysfreesbedryf, wat doeltreffende en duursame rysfrees -eenhede aan kliënte wêreldwyd bied. Die redes vir die keuse van Taizy sluit in:

- Betroubare kwaliteit: Die eenhede is van materiale van hoë gehalte om langtermynstabiele werking te verseker.

- Koste-effektiwiteit: Redelike prys en vinnige opbrengs op belegging, geskik vir klein en mediumgrootte verwerkingsaanlegte.

- Perfekte na-verkope diens: Ons bied installasie -leiding, operasionele opleiding en tegniese ondersteuning op afstand.

- Vertrou deur wêreldwye kliënte: Ons rysfreesaanleg is na baie lande uitgevoer en word wyd geprys.

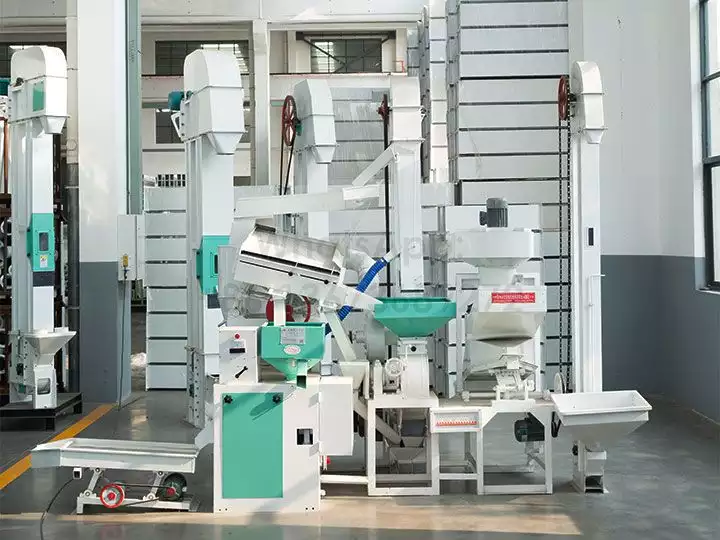

Rysmeule -plantbesoek van wêreldwye kliënte

Taizy se kleinskaalse rysfreesaanleg het kliënte van oor die hele wêreld gelok om die plant te besoek. Kliënte besoek die aanleg om meer te wete te kom oor die vervaardigingsproses, produksievloei en kwaliteitsbeheerstelsel, sowel as om die toerusting te toets om te verseker dat dit aan hul behoeftes voldoen. Hierdie besoeke verhoog nie net die vertroue van die kliënt nie, maar dryf ook ons tegnologiese innovasie en produkoptimalisering.

Nigeriese kliënt besoek Taizy rysmeul fabriek

Ghanaanse kliënt besoek ons rysmeulplant fabriek

Kubaanse kliënt besoek Taizy outomatiese rysmeul eenheid fabriek

Kontak ons nou vir meer besonderhede!

As jy belangstel in rysmeul-eenhede, kontak ons asseblief vrylik! Benewens 15tpd gekombineerde rysmeul, het ons ook 20tpd rysmeulplant, 30tpd rysmeulplant, 15tpd volledige rysmeulproduksielyn, ens. beskikbaar vir jou keuse.

Ons sal jou voorsien van professionele oplossings volgens jou spesifieke behoeftes, asook gedetailleerde kwotasies, tegniese ondersteuning en na-verkope diens. Kom ons help jou rysmeul besigheid saam!