دستگاه بذرکاری مهدکودک اتوماتیک برای کاشت بذر

عملکرد دستگاه نشاکاری، پرورش نشاء انواع سبزیجات، میوه جات و گلها است. این دستگاه میتواند با دستگاه نشاکار برای انجام عملیات بعدی نشاکاری استفاده شود. دستگاه کاشت اتوماتیک بذر ما دارای مزایای کیفیت بالا، انعطافپذیری و کارایی است. علاوه بر این، دستگاه توزیع بذر ما دارای گواهی CE است. دستگاه نشاکاری اتوماتیک در کشورهای خارجی و مناطق مختلف مانند ایالات متحده آمریکا، کانادا، مراکش، کنیا، تایلند، استرالیا، نیجریه و غیره بسیار محبوب است. در صورت علاقه، برای جزئیات بیشتر با ما تماس بگیرید!

6 نوع دستگاه نهال مهد کودک برای فروش

ما به عنوان یک شرکت ماشین آلات بذرکاری مهدکودک حرفه ای، سه نوع دستگاه نهال نهال را برای انتخاب شما داریم. البته ما بر اساس این 4 نوع توابع اضافی قرار می دهیم. حالا یک به یک آنها را معرفی می کنم.

نوع 1: دستگاه بذر مهد کودک KMR-78

شما به وضوح می توانید knاوه که این یک دستگاه سینی سینی دستی از نام و ظاهر آن است. این دستگاه نهال مهد کودک از جنس استیل کربن است و با کمپرسور هوا کار می کند. این دستگاه بذر مهد کودک نیمه اتوماتیک دارای ظرفیت 200 سینی در ساعت است.

ساختار دستگاه نهال نهال نهال نیمه اتوماتیک

دستگاه کاشت سینی دستی دارای ساختار بسیار ساده ای از جمله نازل، میز کار سینی، اتصال کمپرسور هوا می باشد.

چگونه از دستگاه بذرپاشی برای مهد کودک به درستی استفاده کنیم؟

با انجام صحیح عملکرد دستگاه بذرپاش سینی دستی، نه تنها میزان کاشت بذر را افزایش داده و میزان نهال را بهبود می بخشید، بلکه طول عمر دستگاه را نیز افزایش می دهید. برای اطلاعات بیشتر در مورد نحوه انجام این کار، لطفا ویدیوی زیر را تماشا کنید، بسیار به شما کمک خواهد کرد.

پارامترهای فنی دستگاه بذرپاش دستی

| مدل | KMR-78 |

| ظرفیت | 200 سینی در ساعت |

| اندازه | 1050*650*1150 میلی متر |

| وزن | 68 کیلوگرم |

| مواد | فولاد کربنی |

| جنس نازل | آلیاژ آلومینیوم |

لیست قطعات آسیب پذیر

| نام | معین | دلیل آسیب پذیر |

| شیر کنترل هوا | 3A110-06-NC | کار مکرر |

| نازل مکش | 0.5-07 | تغییر شکل خمشی و مسدود کردن |

نوع 2: ماشین کاشت خودکار KMR-78-2

دستگاه پخش بذر KMR-78-2 به طور خودکار پوشش خاک، مسواک زدن، حفاری، کاشت و پوشش خاک و برس زدن مجدد را تکمیل می کند. به دلیل سه قسمت قابل جابجایی، می توانیم آنها را با توجه به خواسته های مشتریان اختصاص دهیم.

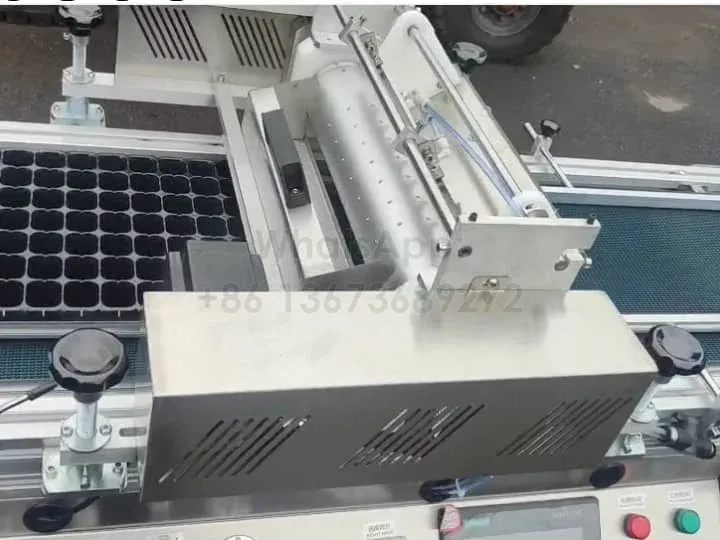

طراحی ماشین کاشت سینی اتوماتیک

| 1. ظرف خاک | 2. تخته لایه | 3. حفر چاله | 4. دانه را در سینی بریزید | 5. نوار نقاله برای سینی |

| 6. ظرف خاک | 7. دانه ها را در سوراخ قرار دهید | 8. جذب دانه | 9. تنظیم سرعت برای قلم مو | 10. تنظیم سرعت |

| 11. دانه را برای خاک تنظیم کنید | 12. تنظیم سرعت برای قلم مو | 13. تنظیم سرعت | 14. تنظیم سرعت برای خاک |

پارامترهای فنی دستگاه سینی بذر

| مدل | KMR-78-2 |

| ظرفیت | 500-600 سینی در ساعت |

| دقت | >97-98% |

| اصل | کمپرسور برق و هوا |

| اندازه | 4800*800*1600 میلی متر |

| وزن | وزن |

| مواد | فولاد ضد زنگ |

| ولتاژ | 220 ولت / 110 ولت 600 وات |

| اندازه برای بذر | 0.2-15 میلی متر |

| عرض سینی | ≤540 میلی متر |

| سینی مناسب | 32/50/72/104/105/128/200cell |

نوع 3: دستگاه بذرکاری خودکار مهد کودک KMR-80

این دستگاه نهال مهد کودک از مواد فولادی ضد زنگ، دوام و عمر طولانی استفاده می کند. علاوه بر این، می توانید مواد مغذی را به خاک اضافه کنید. این نوع خاک برای رشد بذر بسیار مفید است. اگر علاقه مند هستید، لطفا در هر زمان برای جزئیات بیشتر با ما تماس بگیرید!

طراحی ماشین نهال نهال

دستگاه کاشت اتوماتیک نهالستان دارای دو قسمت و قابل جداسازی می باشد. یک قسمت پوشش خاک، حفاری و کاشت بذر را یکپارچه کرده است. قسمت دیگر پوشش خاک است. شما می توانید بر اساس خواسته های خود حذف کنید.

پارامترهای فنی دستگاه نهال تایزی

| مدل | KMR-80 |

| ظرفیت | 300-400 سینی در ساعت (سرعت سینی قابل تنظیم است) |

| دقت | >97-98% |

| تجهیزات کمکی | کمپرسور هوا |

| سیستم | سیستم شمارش خودکار فوتوالکتریک |

| مواد | فولاد ضد زنگ |

| ولتاژ/قدرت | 220 ولت، 600 وات، 300 وات |

| حداکثر اندازه برای سینی های نهال | عرض: 320 میلی متر |

| اندازه دانه | 0.3-12 میلی متر |

| بعد | 1700*600*1300 میلی متر |

| وزن | 250 کیلوگرم |

نوع 4: دستگاه بذر سینی اتوماتیک KMR-80-2

دستگاه گیاهچه کاملاً اتوماتیک KMR-80-2 یک نسخه به روز شده از تجهیزات قبلی KMR-80 است که راندمان و دقت کار بالاتری دارد. این روش یک روش تغذیه جانبی با حداکثر عرض تغذیه تا 300 میلی متر را اتخاذ می کند ، که برای طیف گسترده ای از عملیات نهال مناسب است.

در مقایسه با مدل های قبلی ، KMR-80-2 در طراحی بهینه شده است و می تواند با اطمینان بیشتری مراحل مختلفی مانند پخش خاک ، حفاری ، کاشت و پوشش را انجام دهد. کار با آن آسان است و سازگاری قوی دارد ، که به ویژه برای تولید کشاورزی در مقیاس بزرگ مناسب است.

از طریق به روزرسانی ، KMR-80-2 نه تنها پایداری و دوام دستگاه را بهبود می بخشد ، بلکه دقت دستگاه را نیز به ویژه در کاشت دانه های کوچک افزایش می دهد. این می تواند شدت نیروی کار را کاهش داده و راندمان نهال را بهبود بخشد. این یک انتخاب ایده آل برای اکثر تولید کنندگان کشاورزی است.

نوع 5: دستگاه سینی سینی مهد کودک KMR-100 PLC

این جدیدترین تجهیزات پرورش نهال است که برای پاسخگویی به نیازهای درخواستی مشتری راه اندازی شده است. برای سینی های مشکی مخصوص، سینی های سفید و سینی های مشکی معمولی مناسب است. با قسمت آبیاری و نوار نقاله راحت تر کار می کند.

در قسمت حفر چاله و بذرکاری، یک صفحه کنترل PLC برای کنترل کل دستگاه برای کار وجود دارد. برخلاف KMR-78-2 و KMR-80، این دستگاه نهال با تنظیمات کار می کند، نه با سنجش. برای جزئیات بیشتر با ما تماس بگیرید!

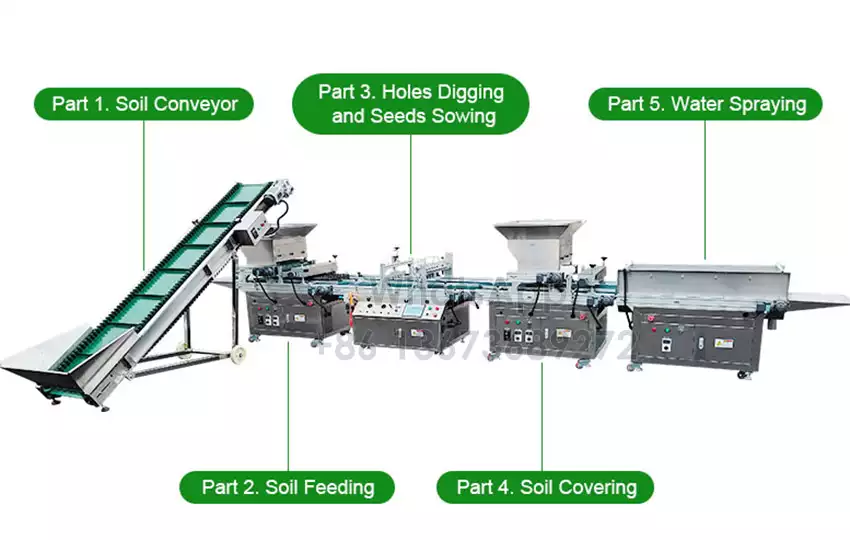

ساختار دستگاه کاشت خودکار نهالستان

این دستگاه از 5 قسمت به ترتیب نوار نقاله خاک، تغذیه خاک، حفر چاله و بذرکاری، تبدیل خاک و آبیاری تشکیل شده است.

اطلاعات فنی دستگاه کاشت سینی

| مدل | KMR-100 |

| ظرفیت | 500-1200 سینی در ساعت (سرعت سینی قابل تنظیم است) |

| دقت | >97-98% |

| اصل | کمپرسور برق و هوا |

| سیستم | سیستم PLC تشخیص خودکار حسگر فوتوالکتریک |

| مواد ماشین | فولاد ضد زنگ |

| قدرت | 650 کیلووات |

| اندازه برای بذر | 0.3-15 میلی متر |

| اندازه سینی | استاندارد معمولی 540 * 280 میلی متر است |

| اندازه | 4800*950*1600mm 5600*950*1600 میلی متر (با قسمت آبیاری) |

| وزن | 400 کیلوگرم 540 کیلوگرم (با قسمت آبیاری) |

نوع 6: ماشین نهال مهد کودک KMR-200

این دستگاه غلتکی برای کاشت بذر در مقیاس بزرگ و نهالستان طراحی شده است که به طور گسترده ای در مهد کودک سبزیجات، گل و محصولات زراعی استفاده می شود. این نوع دستگاه نهال کاشت دقیق و کارآمد بذر را از طریق چرخش غلتک انجام می دهد.

طراحی درام از یک طراحی سوراخ ویژه برای اطمینان از ریزش دقیق بذر در هر سوراخ استفاده می کند که برای نیازهای کاشت در اندازه های مختلف بذر مناسب است. همچنین خط بذر کامل می تواند با مشخصات مختلف سینی های سوراخ دار سازگار باشد تا نیازهای مشتریان مختلف را برآورده کند.

تنظیمات ماشین کاشت مهد کودک اختیاری

گزینه 1: دستگاه دم کردن دانه نهالستان با آبیاری

دستگاه نهال مهد کودک ما دائماً در حال تکامل است و این دستگاه نه تنها در فرآیند کاشت برتر است، بلکه عملکرد آبیاری هوشمندی نیز دارد. این دستگاه کاشت بذر مهدکودکی با ترکیب کاشت و آبیاری محیطی ایده آل برای رشد بذرها فراهم می کند و میزان موفقیت در پرورش نهال را بیشتر می کند. این نوآوری تکنولوژیکی نیروی جدیدی را به کشاورزی مدرن تزریق کرده است.

گزینه 2: دستگاه کاشت نهال سبزی با مجموعه سینی نهال

این دستگاه کاشت سینی اتوماتیک نه تنها در کاشت کارآمد است، بلکه مجهز به سیستم جمع آوری سینی نهال نیز می باشد. پس از کاشت، سینی های نهال را می توان به سرعت و کارآمد جمع آوری کرد و برای دور بعدی کاشت آماده شد. این طراحی نه تنها ثبات عملکرد را بهبود می بخشد، بلکه بار کاری پرورش دهنده را نیز کاهش می دهد.

گزینه 3: دستگاه کاشت سینی اتوماتیک با نوار نقاله

این دستگاه بذرکاری اتوماتیک از تکنولوژی پیشرفته تسمه نقاله استفاده می کند. در طول فرآیند کاشت، تسمه نقاله بستر را به طور دقیق و کارآمد حمل می کند و تداوم فرآیند کاشت را تضمین می کند. این فناوری خودکار کل فرآیند کاشت را تا حد زیادی ساده می کند و بهره وری را افزایش می دهد.

مزایای دستگاه نهال نهال برای فروش

- ابزار کامل جعبه ابزار به خوبی مجهز است و تقریباً تمام ابزارها را پوشش می دهد.

- نازل مکش سالم است. دانههای مختلف به سوزنهای مکنده متفاوتی نیاز دارند، ما 5 سری سوزن مکش داریم که تقریباً همه دانهها را میپوشاند.

- این دستگاه می تواند حفاری و کاشت خودکار را تکمیل کند و در نیروی انسانی صرفه جویی کند.

- نرخ ظهور بالا، نرخ تلفات کم.

- صفحه پلاگین دارای درجه بالایی از سازگاری است. چه یک سینی پلاگین سیاه باشد یا یک سینی پلاگین سفید، چه یک ماده پلی اتیلن یا یک ماده EPS، در دسترس است.

کاربردهای دستگاه بذرکاری مهد کودک

دستگاه نهال نهالستان دارای کاربردهای گسترده ای مانند خربزه، سبزیجات و میوه جات می باشد. جزئیات به شرح زیر است:

چرا Taizy را به عنوان انتخاب برتر برای دستگاه نهال نهال انتخاب کنید؟

ما بیش از 10 سال است که در این منطقه هستیم. در بازار بین المللی، ما قطعا رقابت منحصر به فرد خود را داریم.

- گواهی CE. ما ماشین آلات نهال دارای گواهینامه CE هستند که ثابت می کند ماشین آلات ما با استانداردها مطابقت دارند و هنگام صادرات به هر کشوری مطابقت دارند.

- ماشین سفارشی. این دستگاه را می توان به طور کامل با توجه به نیاز مشتری سفارشی کرد، بنابراین نگران برآورده نشدن نیازهای خود نباشید.

- بدون مشکل پس از فروش. زیرا با دستگاه به 5 مجموعه نازل مکنده مجهز خواهیم شد و جعبه ابزار نیز کاملاً مجهز است، بنابراین تقریباً هیچ مشکلی پس از فروش وجود نخواهد داشت.

تعمیر و نگهداری دستگاه نهال فروشی تعزیه

- بذرهای مازاد را ذخیره کنید و بعد از کاشت دستگاه بذرپاش نهالستان را تمیز کنید.

- هنگامی که دستگاه برای مدت طولانی خاموش است، به دقت تمیز کنید. روغن موتور را در اجزای اتصال و گریس به زنجیر و چرخ تزریق کنید. این دستگاه را در قسمت خشک و هوادهی قرار دهید.

- میل بادامک و ناحیه کاشت پیوند را روغن کاری کنید.

مورد موفقیتآمیز: دستگاه اتوماتیک نهال نهال به کانادا صادر شد

مشتری کانادایی از طریق واتساپ با ما تماس گرفت و گفت که یک دستگاه نشاکاری اتوماتیک برای پرورش نشاء خربزه میخواهد. بنابراین، مدیر فروش ما متوجه شد که مشتری کانادایی به دنبال دستگاه نشاء خربزه است. با توجه به نیازهای او به اتوماسیون، مدیر فروش KMR-78-2 و KMR-80 را توصیه کرد. همچنین، مدیر فروش عملکرد، کارایی و اصل کار دستگاه را برای او توضیح داد. مشتری کانادایی عکسها و ویدیوهایی از دستگاه را درخواست کرد. پس از مشاهده آنها، مشتری MR-78-2 را خریداری کرد، زیرا فکر میکرد این نوع با نیازهای او مطابقت دارد و ظاهر آن را دوست داشت. در نهایت، ما به توافق رسیدیم، دستگاه را بستهبندی کردیم و به مقصد ارسال کردیم.

مشتریان از کارخانه ماشین کاشت بذر بازدید کردند

در صورت نیاز، می توانید برای بازدید به کارخانه ما در چین نیز بیایید. ما دعوت نامه را برای شما آماده می کنیم، خدمات حمل و نقل و همچنین رزرو هتل را ارائه می دهیم و شما را در تمام طول سفر همراهی می کنیم. در زیر تصاویر و ویدئوهایی از بازدید مشتریان زامبیایی ما از کارخانه ماشین آلات نهال نهالستان مشاهده می شود.

ویدیوی بازدید از کارخانه از مشتریان زامبیایی

ویدیوی بازخورد در مورد سینی سینی مهد کودک

بازخورد کنیا در مورد دستگاه نشاکاری نیمه اتوماتیک

بازخورد زیمبابوه و کنیا در مورد دستگاه کاشت سینی دستی