نشاء برنج برای کاشت نهال برنج

دستگاه نشاکار برنج یک ماشین تخصصی برای کاشت نهال برنج در مزارع شالیزار است که باعث صرفهجویی در نیروی کار و تسهیل اجرای روان کارهای بعدی میشود.

ما سه نوع نشاء برنج داریم: 4 ردیفه، 6 ردیفه و 8 ردیفه. دستگاه نشاء برنج 4 ردیفه و 6 ردیفه نیمه اتوماتیک و دستگاه کاشت برنج 8 ردیفه تمام اتوماتیک است.

نشاسته شالیزار Taizy کیفیت عالی و کارایی بالایی دارد و آن را به یک دستیار مکانیکی ضروری برای برنجکاران تبدیل میکند.

اگر شما علاقه مند هستید، لطفا با ما تماس بگیرید و ما در اسرع وقت با شما با راه حل بهینه برای نیازهای شما تماس خواهیم گرفت!

نوع 1: نشاء دستی نهال برنج 4 ردیفه

این دستگاه نشاء برنج دستی 4 ردیفه توسط موتور بنزینی هدایت می شود و باید به صورت دستی کار کند و برای کشت برنج در مقیاس کوچک مناسب است. همچنین یک دستگاه صرفه جویی در کار است که امکان کاشت دقیق را فراهم می کند و از پیوندهای از دست رفته جلوگیری می کند. اگر زمین های کوچکی برای کاشت نهال برنج دارید، این نشاسته برنج پیاده روی انتخاب خوبی برای شما خواهد بود.

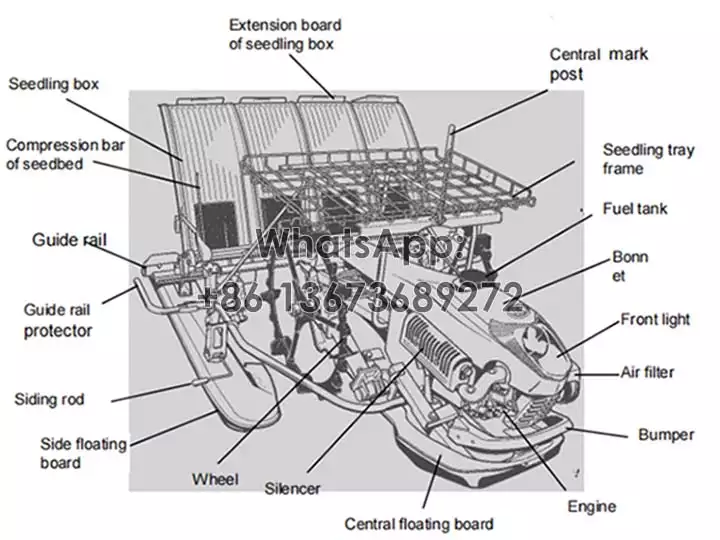

ساختار دستگاه برنجکار 4 ردیفه

به طور کلی، چندین بخش برای تشکیل ساختار برای کشاورزان برنج وجود دارد تا راحت تر و راحت تر کار کنند.

برای نهال های شلتوک، جعبه بذر و قاب سینی بذر قرار است آنها را نگه دارد. به دلیل کار در مزارع آبی، چرخ باید چرخ شالیزار باشد تا به راحتی حرکت کند. برای سیستم قدرت، معمولاً از موتور بنزینی برای پشتیبانی از کار دستگاه استفاده می کند.

اینها فقط چند قسمت هستند، اگر می خواهید بیشتر بدانید، لطفاً به تصویر ساختار زیر مراجعه کنید یا برای جزئیات بیشتر با ما تماس بگیرید!

ویژگی های دستگاه کاشت 4 ردیفه برنج

- هنگام پیوند نهال های برنج با استفاده از دسته تنظیم سرعت و فاصله که محدوده آن 12-14 سانتی متر یا 16-19 سانتی متر است، فاصله را می توان تنظیم کرد.

- هنگامی که دستگاه در مزارع برنج کار می کند، عمق گل باید 15-35 سانتی متر باشد.

- این دستگاه امکان نشاء برنج را به سرعت و کارآمد می دهد و باعث صرفه جویی در نیروی کار می شود و هیچ اشتباه یا کوتاهی در نشاء کاری وجود ندارد.

پارامترهای فنی دستگاه کاشت برنج 4 ردیفه

| مدل | CY-4 |

| تعداد ردیف نشا | 4 |

| قدرت | موتور بنزینی یاماها |

| ابعاد L*W*H(mm) | 1950*1250*1300 |

| سرعت چرخش موتور (r/min) | 1800 |

| فاصله ردیف به ردیف (میلی متر) | 300 |

| فاصله گیاه تا بوته (میلی متر) | 120/140/160/180/210 |

| راندمان پیوند | 0.5 هکتار در ساعت |

| وزن ناخالص | 165 کیلوگرم |

انواع 2: دستگاه نشاء برنج 6 ردیفه پیاده روی

این تجهیزات نشایی شالیزاری 6 ردیفه برای مزارع برنج متوسط قابل استفاده است که برای کشاورزان مقرون به صرفه تر است. دستگاه کاشت برنج 6 ردیفه ما نیز دستی است و هنگام کار یک نفر باید دستگاه را کنترل کند. بنابراین، کار ترکیبی فرد و ماشین را به دست می آورد. اگر علاقه مند هستید، برای جزئیات بیشتر با ما تماس بگیرید!

ویژگی های دستگاه شالیکاری 6 ردیفه

- این نوع نشا برنج دارای محدوده تنظیم 12-14 سانتی متر یا 16-21 سانتی متر است.

- این دستگاه می تواند در زمین هایی که عمق گل 15-35 سانتی متر است کار کند.

- راندمان بالا، کاشت با دقت بالا.

پارامترهای فنی شالیزار دستی 6 ردیفه

| مدل | 2ZS-6 |

| تعداد ردیف نشا | 6 |

| نوع سازه | راه رفتن با دست |

| قطر چرخ (میلی متر) | 660 |

| چرخ | پروانه |

| قدرت | موتور چهار زمانه بنزینی |

| توان خروجی موتور (کیلو وات/دور در دقیقه) | 3.3/3600 |

| ابعاد L*W*H(mm) | 2370*2280*910 |

| فاصله ردیف به ردیف (میلی متر) | 300 |

| فاصله بوته (میلی متر) | 210/180/160/140/120 |

| عمق کاشت (میلی متر) | 15-37 |

| راندمان پیوند (آکر در ساعت) | 0.1-0.25 |

| سرعت کاشت (m/s) | 0.28-0.5 |

| اندازه بسته بندی (میلی متر) | 2810*1760*600 |

| وزن ناخالص (کیلوگرم) | 187 |

| واحد در هر کانتینر 40HQ | 12 مجموعه |

انواع 3: دستگاه نشاء مکانیکی برنج 8 ردیفه

نشاسته برنج 8 ردیفه سواری تعزی یک دستگاه کاشت برنج تمام اتوماتیک با ظرفیت بالا و مناسب برای مزارع بزرگ مقیاس می باشد. هنگام استفاده از این دستگاه، اپراتور می تواند برای کنترل دستگاه بنشیند، که تا حد زیادی باعث صرفه جویی در زمان و قدرت می شود و کاشت نهال برنج شلتوک بسیار راحت تر است.

ویژگی های تجهیزات نشاء برنج 8 ردیفه

- فاصله نشاء را می توان توسط دسته تنظیم کرد تا نیازهای مزرعه شما را برآورده کند.

- وقتی دستگاه در شالیزارها کار میکند، عمق گل ۱۵ تا ۳۵ سانتیمتر است.

- ظرفیت بزرگ، دستگاه سبک وزن، برای رفع نیازهای کشاورزان.

مشخصات نشاء برنج 8 ردیفه برای فروش

| مدل | CY-8 |

| تعداد ردیف نشا | 8 |

| مدل موتور دیزل | 178F |

| ابعاد L*W*H(mm) | 2410*2165*1300 میلی متر |

| خروجی موتور دیزل (kW/HP) | 4.05/5.5 |

| سرعت چرخش موتور دیزل (r/min) | 1800 |

| فاصله ردیف به ردیف (میلی متر) | 238 |

| فاصله تپه تا تپه (میلی متر) | 120/140 |

| راندمان پیوند | 0.5-0.75 هکتار در ساعت |

| اندازه بسته بندی | 2810*1760*600 میلی متر |

| وزن ناخالص | 460 کیلوگرم |

| واحد در هر کانتینر 20 فوتی | 9 ست |

نحوه نشاء برنج در شالیزار چگونه است؟

بررسی قبل از راه اندازی تجهیزات

قبل از شروع کار از سالم بودن تمام عملکردهای نشاء برنج، سطح روغن موتور و خنک کننده مخزن آب کافی و سوخت کافی و عاری از ناخالصی اطمینان حاصل کنید.

بررسی کنید که آیا قطعات محکم به هم وصل شده اند و آیا سوزن های نهال و چنگال های نشاء طبیعی هستند یا خیر.

شروع و تنظیم

روی صندلی راننده بنشینید، ترمز را آویزان کنید و دسته تعویض دنده اصلی را در حالت "پر کردن نهال" یا خنثی قرار دهید و موتور را با دسته کاشت در وضعیت خنثی روشن کنید.

پس از اطمینان از عملکرد روان دستگاه، عمق کاشت و فاصله ردیف ها را با توجه به شرایط خاک و فاصله بین بوته های برنج تنظیم کنید.

آماده سازی و تعیین موقعیت شالیزار

از تراز بودن شالیزار و داشتن رطوبت مناسب اطمینان حاصل کنید و سپس برنجکار را با دقت از طریق فرمان و دستگاه بالابر روی دستگاه قرار دهید تا در امتداد خط کاشت از پیش برنامه ریزی شده حرکت کند.

کاشت برنج و رفع اشکال

نهال های برنج شیرده را به طور مرتب در جعبه نهال قرار دهید و میزان چیدن نهال را طوری تنظیم کنید که یکنواخت و ثابت باشد. درب نهال و مکانیسم تغذیه نهال را راه اندازی کنید، مشاهده کنید که آیا نهال مکیده شده و به آرامی وارد می شود و در صورت لزوم قطعات مربوطه را به موقع تنظیم کنید.

عملیات نشاکاری را شروع کنید

هنگامی که تمام تنظیمات و تنظیمات کامل شد، به آرامی ترمز را رها کنید و به تدریج نشاء برنج را به حالت عادی شتاب دهید. اپراتور باید به اثر پیوند توجه زیادی داشته باشد و در هر زمان تنظیمات را انجام دهد.

تعمیر و نگهداری و بازرسی Midway

در حین کار مداوم، دستگاه را به طور منظم متوقف کنید تا عرضه نهال ها در جعبه نهال را بررسی کنید، ریشه ها یا سایر زباله هایی که ممکن است در قطعات گیر کرده باشند را جدا کنید و تجهیزات را تمیز و در شرایط عملکرد خوب نگه دارید.

تکمیل و تکمیل نهال

می توانید از عملکرد "پر کردن نهال" برای پر کردن مناطق از دست رفته یا پراکنده استفاده کنید. پس از انجام تمام کارهای پیوند، موتور را خاموش کنید، باقیمانده تجهیزات را تمیز کنید و کارهای تعمیر و نگهداری معمولی را انجام دهید تا اطمینان حاصل کنید که عملیات بعدی به خوبی انجام می شود.

لیست قطعات یدکی نشاء برنج شالیزاری

| S/N | نام قطعات پوشیده شده | تصویر |

| 1 | کاربراتور |  |

| 2 | کمربند SB-33 |  |

| 3 | مهر و موم روغن 20×32×7 |  |

| 4 | مجموعه مهر و موم روغن 30×52×12 |  |

| 5 | مجموعه مهر و موم روغن 15×35×11.5 |  |

| 6 | سیم گاز |  |

| 7 | سیم کلاچ فرمان |  |

| 8 | سیم خفه کن |  |

| 9 | تسمه انتقال |  |

| 10 | بازوی کاشت |  |

| 11 | سوزن کاشت |  |

موارد فوق لیستی از قطعات سایش دستگاه نشاء برنج نیمه اتوماتیک می باشد. قسمت ها و عملکردهای مختلف نشاء برنج در نام آن دیده می شود. هنگام خرید یک دستگاه، می توانید چند مجموعه اضافی از قطعات پوشیده را نیز خریداری کنید تا مطمئن شوید که دستگاه به درستی کار می کند.

موارد موفق دستگاه نشاء برنج چندگانه

نشاسته برنج ما دستگاه هایی با کیفیت عالی، عملکرد خوب و ماندگاری طولانی است. به همین دلیل است که آنها در داخل و خارج از کشور بسیار محبوب هستند.

ماشین های ما اغلب به خارج از کشور صادر می شوند، به عنوان مثال به توگو و پاکستان. معمولاً ماشینها را قبل از بارگیری در جعبههای چوبی بستهبندی میکنیم و آنها را از طریق دریا به مقصد مشتری میفرستیم (در صورتی که مشتری روش تحویل دیگری را بخواهد، این امکان نیز وجود دارد).

نحوه سفارش نشاء برنج مکانیکی تعزی؟

- درک محصول و تایید تقاضا: کارکنان فروش ما با تماس با ما به شما کمک میکنند تا پارامترهای فنی، ویژگیهای عملکرد و دامنه کاربرد مدلهای مختلف نشاء برنج را با جزئیات درک کنید و با توجه به اندازه زمین کشاورزی، نیازهای کاشت و بودجه خود، مدل مناسب را انتخاب کنید.

- انتخاب پیکربندی و خدمات سفارشی: با توجه به نیازهای واقعی کاشت، تعیین کنید که آیا نیاز به خرید تجهیزات جانبی اضافی (مانند سینی نهال، دستگاه های کود و غیره) دارید یا الزامات سفارشی سازی خاص، مانند تنظیم فاصله ردیف، فاصله بوته و سایر پارامترها را مطرح کنید.

- نقل قول و مذاکره قرارداد: ما قیمت را ارسال می کنیم و در مورد قیمت خرید، تاریخ تحویل، روش پرداخت و خدمات پس از فروش و غیره ارتباط و مذاکره عمیقی انجام می دهیم. پس از توافق، قرارداد خرید و فروش را تنظیم می کنیم.

- قرارداد را امضا کنید و سپرده را پرداخت کنید: دو طرف قرارداد فروش را به طور رسمی امضا کردند، شما طبق توافق، مبلغ معینی پیش پرداخت یا واریز می کنید تا اطمینان حاصل کنید که سفارش اعمال شده و وارد فرآیند تولید می شود.

- تحویل و نصب و راه اندازی تجهیزات: ما دستگاه را طبق زمان توافق شده تولید می کنیم و دستگاه را تست می کنیم و مابقی مبلغ را طبق قرارداد پس از پذیرش پرداخت می کنید. پس از آن نشاء برنج را به موقع تحویل می دهیم.

برای کاشت برنج خود با ما تماس بگیرید

آیا میخواهید بهرهوری نشاکاری برنج در مزارع شالیزار را افزایش دهید؟ اگر چنین است، با ما تماس بگیرید.

به عنوان یک تولید کننده و تامین کننده جامع کشاورزی، ما همچنین دستگاه نشاکار سبزیجات و دستگاه پرورش نشا برای انواع نشاهای میوه و سبزیجات داریم. ما بهترین راه حل و پیش فاکتور را بر اساس نیازهای شما ارائه خواهیم داد تا ضمن اطمینان از مقرون به صرفه بودن دستگاه، نرخ کاشت برنج شما را نیز تضمین کنیم!