Kiwanda cha Kusaga Mpunga cha 15TPD

Taizy 15TPD kiwanda kamili cha kusaga mchele kinaweza kuchakata mpunga kuwa mchele wa kiwango cha kitaifa katika mchakato mmoja na uwezo wa 600-800kg/h (mchele mweupe). Ni njia kamili ya uzalishaji wa kiwanda cha mchele kiotomatiki inayojumuisha mfululizo wa michakato ya kuondoa mawe, kukoboa, kuchuja, kusaga mchele, kung'arisha mchele, kupanga, kuchagua rangi, na kufungasha.TM

Mill hii ya mchele iliyojumuishwa ina faida za usanidi mwingi (MCTP15-A, MCPT15-B na MCPT15-C), bei nzuri na nzuri, inayopendelea wateja wa Ulimwenguni, Cush kama Nigeria, Ghana, Malawi, Kenya, Cube, Buki Faso, Togoria , nk Ni mmea bora wa milling mchele kwa viwanda vya usindikaji wa mchele, kufaidi biashara zako.

Ikiwa unataka kuanza kiwanda cha kinu cha mchele au unaendesha kiwanda, mstari huu wa uzalishaji wa mchele unaweza kukusaidia kupata faida zaidi. Karibu kuwasiliana nasi na tutatoa suluhisho zinazofaa kwako hivi karibuni!

Aina za 15TPD kamili ya mmea wa milling ya mchele inauzwa

15ton kwa siku mstari wa uzalishaji wa mchele ni kuuza moto, kuingiza miche kamili ya mchele, milling na mashine za michakato ya kufunga. Mtiririko wa kufanya kazi ni kama ifuatavyo:

Kulisha Hopper → Elevator → Desoner → mara mbili lifti → Rice Husker → mara mbili lifti → mvuto paddy mpunga mpunga → Mashine ya Mill Mill → Elevator → Mpunga Polisher → Elevator → White Rice Grader

Kati ya hizi, mlolongo wa polisher ya mchele na grader nyeupe ya mchele inaweza kubadilika. Inategemea mahitaji yako. Kazi ya kila sehemu ya mashine ni:

- Mwangamizi: Ondoa jiwe na uchafu kutoka kwa mchele wa paddy.

- Mchuna mchele: Ondoa ganda la mchele wa paddy.

- Mvuto wa mpunga wa mpunga: Tenganisha mchele wa kahawia na mchele wa paddy.

- Mashine ya kusaga mchele: Piga mchele wa kahawia ndani ya mchele mweupe.

- Kisafishaji cha mchele: Piga mchele mweupe, na kuifanya iwe laini zaidi na nyeupe.

- Daraja la mchele mweupe: Daraja la mchele mweupe na mchele uliovunjika.

- Kipanga rangi: Panga mchele mweupe kulingana na rangi ya mchele, ukitenganisha mchele wenye rangi au rangi isiyo ya kawaida.

- Uzani na mashine ya kufunga: Pakia mchele ndani ya mifuko, kutoka 5-50kg.

Hapo juu ni mechi kamili kwa mstari mzima. Kulingana na mahitaji ya milling ya mpunga wa mteja, tumefanya mchanganyiko tatu maarufu, ambayo ni:

- MCTP15-A: 15TPD Msingi wa mmea wa mchele Na roller polisher & grader nyeupe ya mchele

- MCTP15-B: Kitengo cha Mill cha Mchele wa 15TPD na Sorter ya Rangi na Mashine ya Ufungaji

- MCTP15-C: mmea wa milling wa mchele wa 15TPD na wachinjaji 2 wa mchele na polisher ya maji

Mchanganyiko wa tatu hapo juu ni visasisho vya taratibu vya mmea kamili wa milling wa mchele wa 15TPD, tazama hapa chini kwa maelezo zaidi.

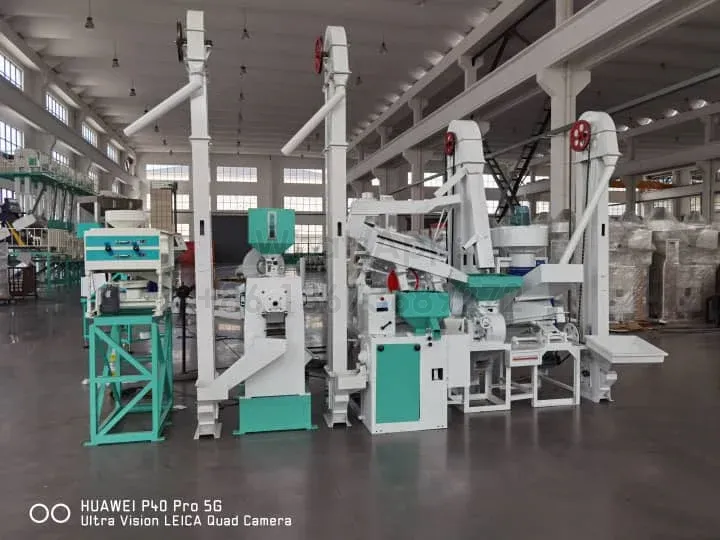

Aina ya 1: 15TPD Msingi wa Mill Mill mmea na Roller Polisher & White Rice Grader (MCTP15-A)

Ushirikiano huu unafaa kwa wanaoanza ambao unazingatia uzalishaji thabiti na uporaji sahihi, kuwa na faida za:

- Thabiti na bora: Roller polisher inaweza kumaliza mchakato wa polishing wa mchele, kuhakikisha kuonekana kwa mchele.

- Grading sahihi: Skrini nyeupe ya upangaji wa mchele inaweza kuweka kiwango cha mchele kulingana na saizi ya chembe za mchele, ambayo inaboresha msimamo na ushindani wa soko la bidhaa.

- Gharama nafuu: Usanidi huhakikisha mahitaji ya msingi ya uzalishaji wakati vifaa ni bei ya chini, inafaa kwa wateja wadogo na wa kati au biashara za kuanza.

- Kubadilika kwa nguvu: Vifaa vya milling ya mchele vinatumika kwa aina ya aina ya mchele, na inaweza kukidhi mahitaji ya usindikaji ya wateja.

Vigezo vya kiufundi vya aina hii ya kiwanda kamili cha kusaga mchele cha 15tpd

| Mfano | Jumla ya nguvu | Uwezo | Ukubwa wa jumla | Uzito | Ufungashaji wa sauti |

| MCTP15-A | 40.35kw | 15T/D (600-800kg/h) | 5500*3000*3000mm | 1700kg | 12cbm |

Mashine kuu za kitengo cha kusaga mchele cha MCTP15-A

| Hapana. | Kipengee | Mfano | Nguvu | Qty |

| 1 | Paddy Rice Desoner | ZQ550 | 0.75+0.75kW | 1pc |

| 2 | Mchuzi wa mchele | LG15 | 4kw | 1pc |

| 3 | Kitenganishi cha mpunga wa mvuto | MGZ70*5 | 0.75kw | 1pc |

| 4 | Kinu cha mchele | NS150 | 15kw | 1pc |

| 5 | Kisafishaji cha mchele | MNMS15F | 15kw | 1pc |

| 6 | Daraja la mchele mweupe | MMJP50*2 | 0.35kW | 1pc |

| 7 | Lifti | TDTG18/07 | 0.75kw | 4pcs |

| 8 | Baraza la mawaziri la kudhibiti umeme | / | / | 1pc |

| 9 | Vumbi Ondoa kifaa | / | / | 1 kitengo |

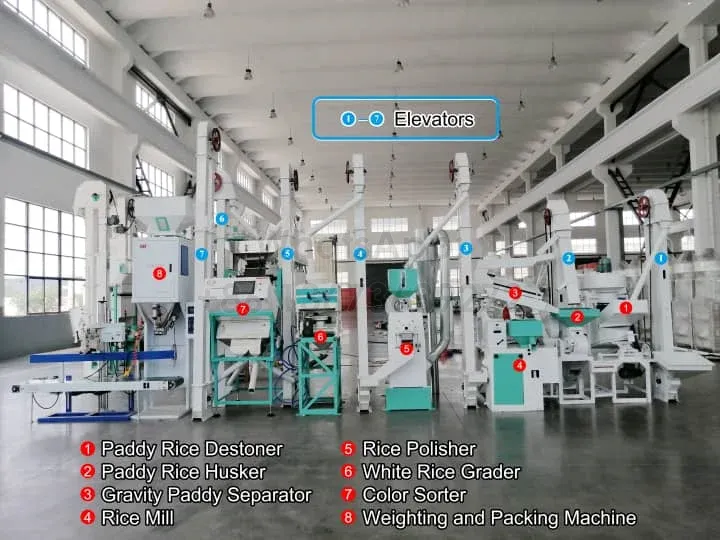

Aina ya 2: 15TPD Kitengo cha Mill ya Mpunga na Sorter ya Rangi na Mashine ya Ufungaji (MCTP15-B)

Usanidi huu unaongeza soter ya rangi na mashine ya kufunga kulingana na MCTP15-A, inayofaa kwa wateja wa kati na kubwa ambao wanataka kuongeza thamani ya bidhaa na automatisering. Nguvu zake zina:

- Usafi wa mwisho: Mchanganyiko wa rangi unaweza kuondoa kabisa uchafu na chembe za rangi ya kigeni kwenye mchele, kuhakikisha kuwa usafi wa bidhaa unafikia kiwango cha juu na unakidhi mahitaji ya soko la mwisho.

- Ufungaji wa kiotomatiki: Kuongezewa kwa mashine ya ufungaji hugundua uzani wa moja kwa moja na ufungaji wa mchele, ambayo inaboresha ufanisi wa uzalishaji na inapunguza gharama za kazi.

- Boresha thamani iliyoongezwa ya bidhaa: Mmea huu kamili wa milling ya mchele unaweza kutoa bidhaa za juu na zenye thamani kubwa, kusaidia wateja kufungua soko la mwisho, na kuongeza picha ya chapa na pembezoni za faida.

- Suluhisho la kuacha moja: Ubunifu wa otomatiki ya mchakato kamili kutoka kwa milling ya mchele hadi ufungaji hutoa wateja na suluhisho la uzalishaji wa kuacha moja. Inafaa kwa wateja wa kati na wakubwa ambao wanataka kuboresha kiwango cha uzalishaji na ubora wa bidhaa.

Data ya kiufundi ya kiwanda cha mashine ya kusaga mchele cha MCTP15-B

| Mfano | Jumla ya nguvu | Uwezo | Ukubwa wa jumla | Pendekezo kuu la eneo la kiwanda | Usafirishaji |

| MCTP15-B | 50.35kW | 15T/D (600-800kg/h) | 10500*4000*4000mm | 13000*7000*4500mm | 20gp |

Mashine za kiwanda cha kusaga mchele kiotomatiki cha MCTP15-B

Kulingana na MCTP15-A, rangi ya rangi na mashine ya ufungaji huongezwa.

| Hapana. | Kipengee | Mfano | Nguvu | Qty |

| 1 | Paddy Rice Desoner | ZQ550 | 0.75+0.75kW | 1pc |

| 2 | Mchuzi wa mchele | LG15 | 4kw | 1pc |

| 3 | Kitenganishi cha mpunga wa mvuto | MGZ70*5 | 0.75kw | 1pc |

| 4 | Kinu cha mchele | NS150 | 15kw | 1pc |

| 5 | Kisafishaji cha mchele | MNMS15F | 15kw | 1pc |

| 6 | Daraja la mchele mweupe | MMJP50*2 | 0.35kW | 1pc |

| 7 | Kipanga rangi | 6SXM-64 (CCD) | 1.5kw | 1pc |

| 8 | Uzani na mashine ya kufunga | DCS-50A | 0.75kw | 1pc |

| 9 | Lifti | TDTG18/07 | 0.75kw | 4pcs |

| 10 | Compressor ya hewa | / | 4kw | 1pc |

| 11 | Baraza la mawaziri la kudhibiti umeme | / | / | 1pc |

| 12 | Vumbi Ondoa kifaa | / | / | 1 kitengo |

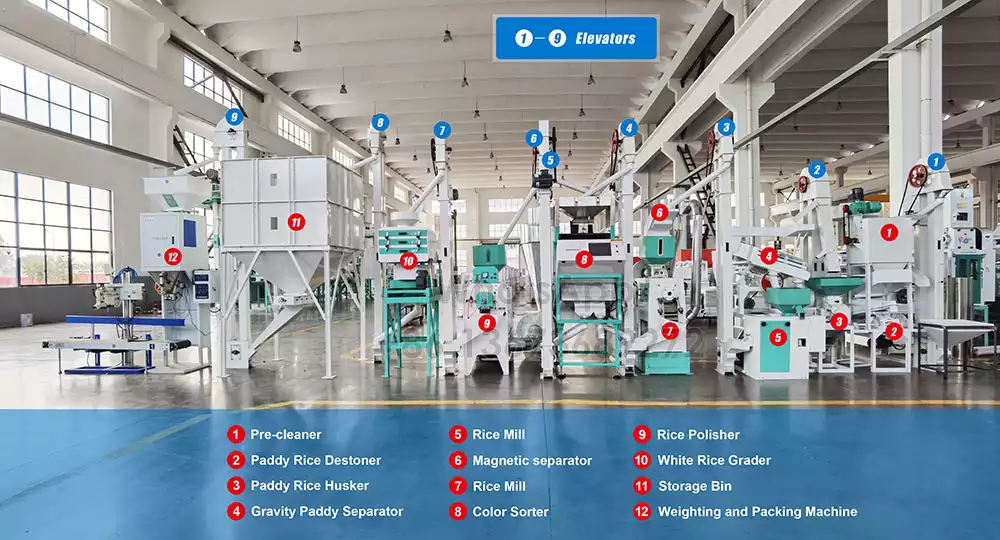

Aina ya 3: 15TPD mmea wa milling mchele na miller 2 ya mchele na polisher ya maji (MCTP15-C)

Huu ni usanidi wa hali ya juu wa Standanard, na kuongeza polisher ya maji kulingana na MCTP15-B, inayofaa kwa wateja wadogo na wa kati ambao hufuata utendaji wa gharama kubwa na ubora wa hali ya juu. Vivutio vyake ni:

- Usindikaji mzuri: Imewekwa na seti 2 za mashine ya milling ya mchele, ina uwezo wa kukamilisha haraka mchakato wa kuchora na weupe wa mchele wa paddy, ambayo inaboresha sana ufanisi wa uzalishaji.

- Uimarishaji wa gloss ya mchele: Kuongezewa kwa mashine ya kusaga maji na polishing hufanya uso wa mchele kuwa laini na kuvutia zaidi kwa kuonekana, kukidhi mahitaji ya mteja ya mchele wa hali ya juu.

- Kiuchumi na vitendo: Aina hii ya mmea kamili wa milling ya mchele huhakikisha ufanisi mkubwa wa uzalishaji wakati uwekezaji wa vifaa na gharama za uendeshaji ni chini. Inafaa kwa wateja wadogo na wa kati na bajeti ndogo lakini katika kutafuta ubora wa hali ya juu.

- Rahisi kufanya kazi: Muundo wake ni rahisi, rahisi kufanya kazi na kudumisha, inafaa kwa wateja wanaoingia kwenye tasnia ya usindikaji wa nafaka kwa mara ya kwanza.

Maelezo ya kiufundi ya kiwanda cha pamoja cha kusaga mchele cha MCTP15-C

| Mfano | Jumla ya nguvu | Uwezo | Ukubwa wa jumla | Pendekezo kuu la eneo la kiwanda | Usafirishaji |

| MCTP15-C | 76.34kW | 15T/D (600-800kg/h) | 12500*4000*4000mm | 15000*8000*4500mm | 20gp |

Mashine za njia kamili ya uzalishaji wa kiwanda cha mchele cha MCTP15-C

Kulingana na MCTP15-B, miller mwingine wa mchele na polisher ya maji huongezwa.

| Hapana. | Kipengee | Mfano | Nguvu | Qty |

| 1 | Msafishaji wa mapema | SCQY40 | 0.55kw | 1pc |

| 2 | Paddy Rice Desoner | ZQ550 | 0.75+0.75kW | 1pc |

| 3 | Mchuzi wa mchele | LG15 | 4kw | 1pc |

| 4 | Kitenganishi cha mpunga wa mvuto | MGZ70*5 | 0.75kw | 1pc |

| 5 | Kinu cha mchele | NS150 | 15kw | 1pc |

| 6 | Mgawanyaji wa sumaku | / | / | 1pc |

| 7 | Kinu cha mchele | MNMS15F | 15kw | 1pc |

| 8 | Kipanga rangi | 6SXM-64 (CCD) | 1.5kw | 1pc |

| 9 | Polisher ya maji | MP12.5 | 22kw | 1pc |

| 10 | Daraja la mchele mweupe | MMJP50*2 | 0.35kW | 1pc |

| 11 | Bin ya kuhifadhi | 3t | / | / |

| 12 | Uzani na mashine ya kufunga | DCS-50A | 0.75kw | 1pc |

| 13 | Lifti (1-9) | TDTG18/07 | 0.75kW*9 | 9pcs |

| 14 | Compressor ya hewa | / | 4kw | 1pc |

| 15 | Baraza la mawaziri la kudhibiti umeme | / | / | 1pc |

| 16 | Vumbi Ondoa kifaa | / | / | 1 kitengo |

Je! Ni bei gani ya Taizy 15TPD kamili ya mmea wa milling ya mchele?

Bei ya kitengo kamili cha milling ya mchele hutofautiana kulingana na usanidi, uwezo na kiwango cha kiufundi. Kwa ujumla, bei ya mmea wa kisasa wa mchele wa 15TPD na usanidi wa msingi ni wa kiuchumi zaidi na unaofaa kwa biashara ndogo na za kati zilizo na bajeti ndogo. Bei ya laini ya milling ya mchele iliyo na vifaa vya mwisho wa juu (kama vile rangi ya rangi na mashine ya kufunga) ni kubwa zaidi, lakini inaweza kuboresha ufanisi wa uzalishaji na ubora wa bidhaa. Hii inafaa kwa biashara za ukubwa wa kati na wakubwa au wateja wanaofuata thamani kubwa.

Kwa jumla, mmea wetu kamili wa milling ya mchele hutoa chaguzi rahisi za usanidi ili kukidhi bajeti tofauti za wateja na mahitaji wakati wa kuhakikisha utendaji wa hali ya juu na kuegemea. Bei maalum zinaweza kuboreshwa na kunukuliwa kulingana na mahitaji halisi ya wateja.

Huduma kutoka Taizy 15TPD Kukamilisha Mmea wa Milling

Taize hutoa wateja na msaada kamili wa huduma ili kuhakikisha operesheni laini na utumiaji wa muda mrefu wa kitengo cha milling cha mchele cha 15TPD:

- Video na msaada mkondoni

- Tunatoa video ya operesheni ya kina na msaada wa kiufundi wa wakati halisi wa kusaidia wateja haraka kutumia vifaa na kutatua shida katika operesheni.

- Uainishaji wa kiufundi na mwongozo wa operesheni

- Kila seti ya mmea kamili wa milling ya mchele unaambatana na vigezo vya kiufundi vya kina na mwongozo wa operesheni, ambayo ni rahisi kwa wateja kuangalia habari ya vifaa na uainishaji wa operesheni wakati wowote.

- Huduma ya baada ya mauzo

- Tunayo timu ya huduma ya baada ya mauzo ili kutoa wateja na matengenezo ya vifaa, utatuzi wa shida na huduma za uingizwaji wa sehemu. Hii inahakikisha operesheni ya muda mrefu ya mmea wa mashine ya milling ya mchele.

- Kipindi cha udhamini

- Vifaa vyote hutolewa kwa kipindi fulani cha huduma ya dhamana. Katika kipindi cha dhamana kwa sababu ya shida za ubora wa vifaa zinazosababishwa na kutofaulu, tutatoa huduma za matengenezo ya bure, ili wateja hawana wasiwasi.

Jinsi ya kusambaza na kutoa mmea kamili wa milling mchele?

Kwa ujumla, tunapakia mstari kamili wa uzalishaji wa mchele wa mchele katika kesi za mbao, ili kuhakikisha usalama wa mashine zote. Mbali na hilo, tutafanya video kuhusu kila mashine, pamoja na maelezo ya mashine. Sisi pia hufanya viwango madhubuti vya kupakia na kupakia mashine kwenye chombo.

Wasiliana nasi sasa kwa maelezo zaidi!

Je, una nia ya kusaga mchele? Je, ungependa kupata mchele mweupe? Ikiwa ndiyo, njoo na uwasiliane nasi wakati wowote. Tutakupa suluhisho linalofaa zaidi ili kuwezesha biashara yako!