اناج، مکئی، چاول، گندم کے لیے پیڈی ڈرائر

Paddy dryer is ideal equipment that mainly functions to dry various grains, such as corn, rice, wheat, soybean, etc. The grain dryer belongs to batch circulation dryer, low temperature, and energy saving. It has a reasonable structure, easy operation, and low noise.

عام طور پر، Taizy کمپنی کی طرف سے فروخت کے لیے اناج خشک کرنے والے 5H-15 اور 5H-32 دستیاب ہیں۔ اس کے علاوہ، حرارتی طریقہ اختیاری ہے. ٹاور ڈرائر تجارتی استعمال کے لیے عام ہے۔

مثال کے طور پر، رائس مل پلانٹ میں، اس مشین کو چاول کے خشک کرنے والے کے طور پر استعمال کیا جاتا ہے تاکہ دھان کے مطمئن چاول حاصل کیے جا سکیں۔ اسی نظریہ کے تحت، اسے کارن ڈرائر کے طور پر بھی لاگو کیا جا سکتا ہے۔ مزید تفصیلات کے لیے ہم سے رابطہ کرنے میں خوش آمدید!

پیڈی ڈرائر برائے فروخت کے تکنیکی پیرامیٹرز

| ماڈل | 5H-15 | 5H-32 |

| خشک کرنے کی صلاحیت | 15-20t·%/h | 25-35t·%/h |

| کھانا کھلانے کا وقت | تقریباً 63 منٹ | تقریباً 58 منٹ |

| خارج ہونے کا وقت | تقریباً 69 منٹ | تقریباً 64 منٹ |

| طاقت | 6.5kW (82/3HP) | 12.65 کلو واٹ |

| کل وزن | 3200 کلوگرام | 7500 کلوگرام |

کم درجہ حرارت کا سرکلر پیڈی ڈرائر ڈیزائن

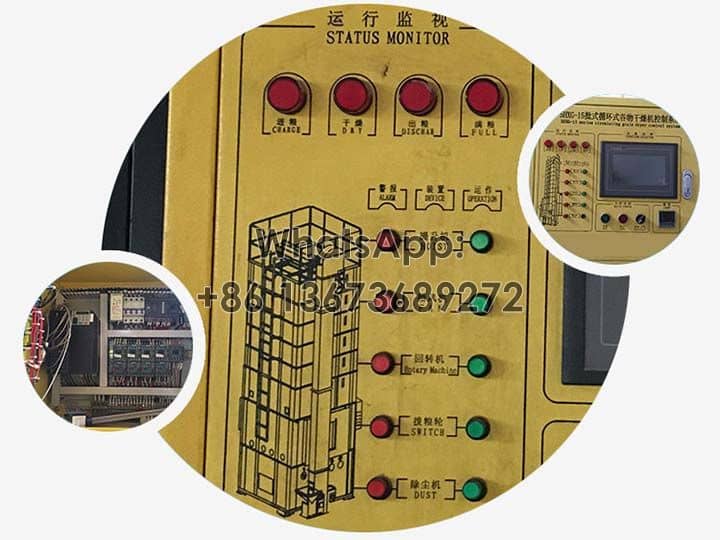

PLC control cabinet

سیمنز الیکٹرک، ٹچ اسکرین آپریشن، درست فالٹ ڈسپلے

Heating methods

گرمی کے مختلف ذرائع آپ کی پسند کے لیے ہیں: بایوماس گرم دھماکے کا چولہا، ڈیزل کا چولہا، قدرتی گیس، الیکٹرک برنر۔ ایک کا انتخاب آپ کے فوائد کو زیادہ سے زیادہ کرتا ہے۔

Elevator

بیلٹ خالص نایلان کینوس بیلٹ سے بنی ہے، بالٹی اچھی سختی کے ساتھ کنواری نایلان پلاسٹک کا استعمال کرتی ہے اور بغیر کسی ٹوٹ پھوٹ کے۔

Paddy dryer design calculation

زاویہ کی مقدار، خشک اناج کو سہولت فراہم کرنا.

رائس ڈرائر کے فوائد برائے فروخت

- آسان استعمال. کیونکہ اس پیڈی ڈرائر کو کسی بھی حصے کو تبدیل کرنے کی ضرورت نہیں ہے، براہ راست خشک مکئی، چاول، گندم، ریپسیڈ، سویا بین، وغیرہ کے مطابق۔

- اعلی درجے کی اناج خشک کرنے والی ٹیکنالوجی. یہ ٹیکنالوجی اناج کو یکساں طور پر گرم کرتی ہے، پانی کی تیز رفتار اور کم خشک کرنے والی لاگت۔

- سٹینلیس سٹیل کا مواد. اناج ڈرائر کے اندر کے اہم حصے سٹینلیس سٹیل کے مواد کو اپناتے ہیں، مؤثر طریقے سے آلات کی سروس کی زندگی کو بڑھاتے ہیں۔

- کارن ڈرائر کے پاس ہے۔ اپنا کولنگ ایئر ڈسٹری بیوشن سسٹم، جو خشک اناج کے معیار کو مؤثر طریقے سے یقینی بنا سکتا ہے اور اناج کے تحفظ کو آسان بنا سکتا ہے۔

- آسان آپریشن، اعلی خشک کرنے والی کارکردگی، آلودگی سے پاک۔

- اختیاری حرارتی طریقے. بایوماس گرم دھماکے کا چولہا، ڈیزل کا چولہا، قدرتی گیس، الیکٹرک برنر دستیاب ہیں۔

عمودی اناج ڈرائر کی وسیع ایپلی کیشنز

This vertical grain dryer has a various range of applications. It can dry grains, such as rice, wheat, corn, soybean, sorghum, millet, rapeseed, sunflower seed, etc. in batch type.

کچا پیڈی ڈرائر کیسے کام کرتا ہے؟

کھانا کھلانے کا مرحلہ

دھان کو خشک کرنے کا عمل شروع کرنے سے پہلے، کٹے ہوئے گیلے دھان کو پہلے اسٹیجنگ ایریا سے لے کر دھان کے ڈرائر کے اندر جانے والے آلات (جیسے بالٹی لفٹ یا بیلٹ کنویئر) کے ذریعے اناج کی ابتدائی لوڈنگ مکمل کرنے کے لیے کھلایا جاتا ہے۔

پری ہیٹنگ کی تیاری

اس سے پہلے کہ ڈرائر مکمل طور پر دھان سے بھر جائے، آپریٹر کو ڈرائر کے اندر برنر کو آن کرنے کی ضرورت ہے۔ سامان کی قسم پر منحصر ہے، تیل، گیس، بایوماس یا توانائی کی دیگر اقسام کو یقینی بنانے کے لیے استعمال کیا جا سکتا ہے کہ برنر مستقل طور پر جلتا رہے اور خشک کرنے کے عمل کے لیے گرمی کا ذریعہ فراہم کرنے کے لیے کافی حرارت پیدا کرے۔

سرکلر خشک کرنے کا عمل

جب دہن کی بھٹی پہلے سے طے شدہ درجہ حرارت پر پہنچ جاتی ہے اور مسلسل گرمی کی فراہمی شروع کر دیتی ہے، تو ڈرائر کا گردشی نظام شروع ہو جاتا ہے۔

یہ بنیادی طور پر دھان کے ساتھ گرمی کا تبادلہ کرنے کے لیے فرنس چیمبر میں پیدا ہونے والی حرارت پر انحصار کرتا ہے۔ گرم ہوا ڈرائر کے اندر گردش کرتی ہے اور دھان کو ملٹی لیئر ڈرائینگ پلیٹوں یا خاص طور پر تیار کردہ خشک کرنے والے چینلز کے ذریعے یکساں طور پر گرم کرتی ہے تاکہ اس سے نمی کو دور کیا جا سکے۔

خشک ہونے اور خارج ہونے کا اختتام

خشک کرنے کا عمل اس وقت مکمل ہو جاتا ہے جب دھان میں نمی ذخیرہ کرنے کے لیے موزوں معیار تک کم ہو جاتی ہے۔ دہن کی بھٹی کو بند کریں، ڈرائر کے ڈسچارج ڈیوائس کو ایڈجسٹ کریں، ڈرائر کے نیچے سے یا مخصوص آؤٹ لیٹ سے مقررہ رفتار کے مطابق ترتیب سے خارج ہونے والے دھان کو کنٹرول کریں۔

خشک ہونے کے بعد، دھان کو ٹھنڈا کر دیا جاتا ہے اور ذخیرہ کرنے یا پروسیسنگ کے اگلے مرحلے کے لیے تیار کیا جاتا ہے۔

اناج پیڈی ڈرائر خریدتے وقت اکثر پوچھے گئے سوالات

آپ کس قسم کے اناج کو خشک کرنا چاہتے ہیں؟ چاول، مکئی، جوار، گندم یا دیگر اناج؟

ہمارا اناج ڈرائر مندرجہ بالا تمام چیزوں کو خشک کر سکتا ہے۔

آپ فی بیچ یا دن میں کتنے ٹن خشک کرنا چاہتے ہیں؟

ہماری اناج خشک کرنے والی مشین بیچوں میں کام کرتی ہے، عام طور پر 15 ٹن/بیچ یا 32 ٹن/بیچ۔ اگر آپ کو بڑی صلاحیت کی ضرورت ہے، تو ہم اسے آپ کے لیے بھی لیس کر سکتے ہیں۔

خشک ہونے سے پہلے نمی کتنی ہے؟ خشک ہونے کے بعد آپ کیا نمی حاصل کرنا چاہتے ہیں؟

عام طور پر، خشک ہونے سے پہلے، نمی 40% ہوتی ہے۔ خشک ہونے کے بعد، آپ چاہتے ہیں کہ یہ 20% ہو۔

جلنے والی بھٹی کے لیے، آپ کوئلہ، ڈیزل اور بائیو ماس کو بطور ایندھن منتخب کر سکتے ہیں۔ آپ کس کو ترجیح دیتے ہیں؟

ہمارا کارن ڈرائر ان سب کو استعمال کر سکتا ہے۔

مندرجہ بالا چار سوالات بنیادی معلومات ہیں جو آپ کی ضروریات کو بہتر طور پر سمجھنے میں ہماری مدد کرتے ہیں۔ ہم آپ کے کاروبار کے لیے مناسب تجارتی پیڈی ڈرائر تجویز کر سکتے ہیں۔ ہم سے رابطہ کریں اور ہم جلد از جلد آپ سے رابطہ کریں گے!

گرین ڈرائر کی قیمت کے لیے ہم سے رابطہ کریں!

Come and contact us for the dryer for corn, rice, wheat and soybean! Our corn dryer machine can help you dry your grains quickly and in batches. And our machine has a competitive price, which attracts you!