Paddy Dryer for Grain, Corn, Rice, Wheat

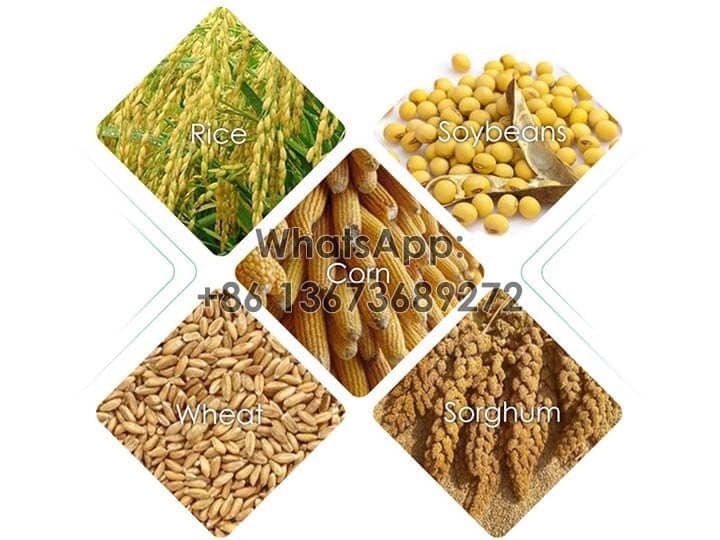

Paddy dryer is ideal equipment that mainly functions to dry various grains, such as corn, rice, wheat, soybean, etc. The grain dryer belongs to batch circulation dryer, low temperature, and energy saving. It has a reasonable structure, easy operation, and low noise.

Generally speaking, grain dryers for sale from Taizy Company have 5H-15 and 5H-32 available. Besides, the heating method is optional. The tower dryer is common for commercial usage.

For example, in the rice mill plant, this machine is used as rice dryer to get satisfied paddy rice. Under the same theory, it also can be applied as corn dryer. Welcome to contact us for more details!

Technical Parameters of Paddy Dryer for Sale

| Model | 5H-15 | 5H-32 |

| Drying capacity | 15-20t·%/h | 25-35t·%/h |

| Feeding time | About 63min | About 58min |

| Discharge time | About 69min | About 64min |

| Power | 6.5kW (82/3HP) | 12.65kW |

| Total weight | 3200kg | 7500kg |

Low-Temperature Circular Paddy Dryer Design

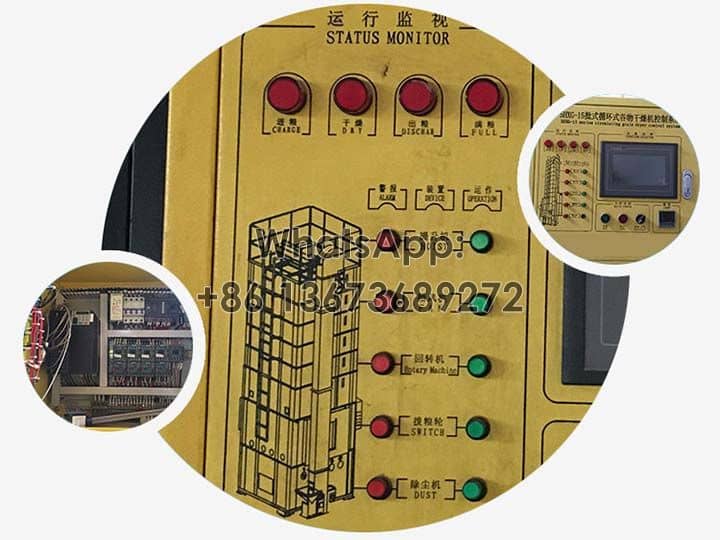

PLC control cabinet

Siemens electric, touch screen operation, accurate fault display

Heating methods

Various heat sources are for your choice: biomass hot blast stove, diesel stove, natural gas, electric burner. Choosing one maximizes your benefits.

Elevator

The belt is made of pure nylon canvas belt, the bucket uses virgin nylon plastic with good toughness and no brittleness.

Paddy dryer design calculation

Angle intake, facilitating to dry grains.

Advantages of Rice Dryer for Sale

- Convenient usage. Because this paddy dryer does not need to replace any parts, directly adapting to dry corn, rice, wheat, rapeseed, soybean, etc.

- Advanced grain drying technology. This technology heats grains evenly, fast dewatering rate and low drying cost.

- Stainless steel material. Key parts of the grain dryer inside adopt stainless steel materials, effectively extending the service life of the equipment.

- The corn dryer has its own cooling air distribution system, which can effectively ensure the quality of dried grain and facilitate the preservation of grain.

- Easy operation, high drying efficiency, pollution-free.

- Optional heating methods. Biomass hot blast stove, diesel stove, natural gas, electric burner are available.

Wide Applications of Vertical Grain Dryer

This vertical grain dryer has a various range of applications. It can dry grains, such as rice, wheat, corn, soybean, sorghum, millet, rapeseed, sunflower seed, etc. in batch type.

How does A Raw Paddy Dryer Work?

Feeding stage

Before starting the paddy drying process, the harvested wet paddy is first fed from the staging area to the inlet of the paddy dryer through the lifting equipment (e.g. bucket elevator or belt conveyor) to complete the initial loading of the grain.

Preheating preparation

Before the dryer is completely filled with paddy, the operator needs to switch on the burner inside the dryer. Depending on the type of equipment, oil, gas, biomass or other forms of energy may be used to ensure that the burner burns steadily and generates sufficient heat to provide a source of heat for the drying operation.

Circular drying process

When the combustion furnace reaches a predetermined temperature and begins to supply heat steadily, the circulating system of the dryer is started.

It mainly relies on the heat generated in the furnace chamber to exchange heat with the paddy. The hot air circulates inside the dryer and heats the paddy uniformly through the multi-layer drying plates or specially-designed drying channels to remove the moisture from it.

End of drying and discharging

The drying operation is completed when the moisture in the paddy is reduced to a standard suitable for storage. Switch off the combustion furnace, adjust the discharge device of the dryer, control the paddy to be discharged orderly from the bottom of the dryer or the specific outlet according to the set speed.

After drying, the paddy is cooled down and ready for the next step of storage or processing.

FAQ When Buying Grain Paddy Dryer

What kind of grains do you want to dry? Rice, corn, sorghum, wheat or other grains?

Our grain dryer can dry all the above.

How many tons do you want to dry per batch or day?

Our grain drying machine works in batches, usually 15 tons/batch or 32 tons/batch. If you need bigger capacity, we can also equip it for you.

What’s the humidity before drying? What humidity do you want to get after drying?

Usually, before drying, the humidity is 40%; after drying, you want it to be 20%.

For the burning furnace, you can choose coal, diesel, and biomass as fuel. Which one do you prefer?

Our corn dryer can use all these.

The above four questions are basic information to help us better understand your requirements. We can recommend a suitable commercial paddy dryer for your business. Get in touch with us and we’ll get back to you as soon as possible!

Contact Us for Grain Dryer Price!

Come and contact us for the dryer for corn, rice, wheat and soybean! Our corn dryer machine can help you dry your grains quickly and in batches. And our machine has a competitive price, which attracts you!