Corn Silage Baling and Wrapping Machine for Livestock

Taizy silage baler is bundling and wrapping the crushed grass, silage, etc., into silage round bales(available sizes of Φ55*52cm, Φ60*52cm, Φ70*70cm, or Φ90*90cm) as animal feeds for preparation. It can make silage bales of 50-85 pcs per hour, and one silage bale weighs 65-500 kg.

This silage round baler can use a diesel engine or an electric motor to reliably feed, bundle, and wrap the rubbed feed, like corn stalks, necessary equipment for animal husbandry like dairy farms. We have four types of silage balers for sale, respectively model 50(TZ-55-52 & 9YDB-55), model 60(9YDB-60 & T60), model 70(9YDB-70), and model 90(9YDB-90).

Our silage baling machine can store and transport the feed in a convenient situation. After wrapping the feed, the feed is insulated from the oxygen. During the storage time, the feed is fermented, which is more conducive to animal digestion. At the same time, it can preserve nutrition very well.

Now we upgrade our silage baler and wrapper with a PLC control panel and fully automatic baling, wrapping and film cutting without manual help.

The corn silage baler and wrapper has been exported to many countries, such as Kenya, South Africa, Algeria, Burkina Faso, Georgia, Thailand, Mexico, the UK, etc. Get in touch with us to get more details for facilitating your business!

What is Corn Silage Baler?

The baling and wrapping machine is a large-capacity, multi-use green storage baling and wrapping machine. It is a new type of green storage feed processing machine developed by Taizy at the request of our customers.

It is mainly a good helper for animal husbandry. In addition, the machine runs stably, the equipment cost is low, the baling efficiency is high, the operation is simple, and the operation is smooth, thus, it is the choice of the majority of herdsmen. You only need to press a button, which can realize the automatic wrapping. Looking forward to your inquiry! Now let’s see the machine details.

Type 1: TZ-55-52 & 9YDB-50 Small Round Silage Baler Wrapper (55*52cm)

This one is the best-selling mini silage baling and wrapping machine. The electric motor and diesel engine can be used to support the machine’s work. Also, the dry or wet grass can be baled into round shapes. It is a fixed bundling machine.

It can make silage bales of Φ55*52cm, one bale weighs 65-100kg, and the bale density is 450-500kg/m³. Its capacity is 50-60pcs per hour and 5-6t/h. All these make it ideal for small farms and agro distributors.

This year, we upgraded our silage packing machine to a fully automatic type. Thus, now this grass baler machine can automatically silo opening, silage wrapping and film cutting. With continuous technological advancements, we have now developed the Super Model. We currently offer two models of the 50-series equipment: TZ-55-52 and High Standard 9YDB-55 Silage Bailer.

Comparison of TZ-55-52 VS. 9YDB-55 Silage Baler Machine

Below is a summary of this popular silage bale making machine. The following table clearly shows the differences in the strapping materials used.

| Model | TZ-55-52 | 9YDB-55 |

| Power | Diesel engine, electric motor | Diesel engine, electric motor |

| Available bundling material | Rope, plastic net | Plastic net, transparent film |

| Bale size | Φ550*520mm | Φ550*520mm |

| Bale weight | 65-100kg/bale | 65-100kg/bale |

| Bale density | 450-500kg/m³ | 450-500kg/m³ |

| Capacity | 50-60pcs/h, 5-6t/h | 50-60pcs/h, 5-6t/h |

| Method for bundling materials feeding | Roller feeding | Cylinder feeding |

Besides, in 2025, based on customer feedback, the diesel-engine silage packing machine has been upgraded. The PLC control cabinet is now separated from the machine. This design prevents vibrations generated during machine operation from affecting the control cabinet. If you have such requirements, we can customize it for you.

Advantages of Silage Bale Wrapper

- Integrated baling and wrapping design

- Combine baling, compaction, and wrapping into one unit, completing the entire silage production process with a single machine to reduce equipment investment and labor costs.

- High compaction density for superior fermentation

- It achieves high compaction, producing tightly packed bales with minimal air pockets. This promotes lactic acid fermentation, resulting in more stable silage quality and reduced mold susceptibility.

- Ideal for small to medium-sized farms and distributors

- Compact footprint, simple operation, and moderate size make it perfect for dairy farms, sheep farms, family farms and dealers.

- Automatic wrapping with strong sealing

- Multi-layer stretch film automatically wraps for superior sealing, enabling long-term storage (1–2 years) and reducing feed waste.

- Multiple power options available

- Support electric motor or diesel engine configurations to adapt to varying power supply and operational environments across different countries.

- Simple maintenance, low operating costs

- A well-designed structure with low failure rates, making it easy to maintain and suitable for long-term, high-frequency use.

Structure of Mini Silage Baler for Sale

Its structure is very simple, mainly conveying, bundling, and wrapping. It’s a fully automatic silage baling machine. Details are shown below:

Technical Parameters of the Silage Wrapping Machine

Parameters of TZ-55-52 hay bale making machine

| Model | TZ-55-52(with electic motor) | TZ-55-52(with diesel engine) |

| Power | 5.5+1.1kW, 3 phase | 15hp diesel engine |

| Bale size | Φ550*520mm | Φ550*520mm |

| Baling speed | 50-60pcs/h, 5-6t/h | 50-60pcs/h, 5-6t/h |

| Machine size | 3380*1370*1300mm | 3520*1650*1650mm |

| Machine weight | 456kg | 850kg |

| Bale weight | 65-100kg/bale | 65-100kg/bale |

| Bale density | 450-500kg/m³ | 450-500kg/m³ |

| Film wrapping speed | 13s for 2-layer film,19s for 3-layer film | 13s for 2-layer film,19s for 3-layer film |

Parameters of 9YDB-55 silage wrapping machine

| Model | 9YDB-55 |

| Power | 5.5+0.55kW |

| Bale size | Φ550*520mm |

| Baling speed | 50-60pcs/h, 5-6t/h |

| Size | 3500*1500*1600mm |

| Weight | 500kg |

| Bale weight | 65-100kg/bale |

| Bale density | 450-500kg/m³ |

| Film wrapping speed | 13s for 2-layer film,19s for 3-layer film |

Optional Power for the Mini Round Baler

In Zhengzhou Taizy Machine Company, we supply diesel engines and electric motors.

Firstly, you should understand which needs the power to run. For this silage baler machine, the main machine, the wrapping frame, and the air compressor need the power to support it.

And then, get to know the differences between them. The diesel engine can provide power by itself. But the electric motor should get help from the electricity. So, you can choose the suitable power according to your actual demands.

Customized Silage Baling and Wrapping Machine with Traction Frame & Big Tyres

In order to meet the special needs of our customers, we have tailored a baling and wrapping machine equipped with large tires and a tractor frame, which can be easily connected with a tractor for free movement.

This equipment not only enhances operational flexibility, but also adapts to the needs of different plots, bringing great convenience to customers. Whether it’s silage production or field work, this customized baler and wrapper can efficiently complete the task and help customers upgrade and optimize their agricultural production!

With the ever-changing needs of our customers and the advancement of technology, we are constantly upgrading this small baling and wrapping machine, so please read for details: upgrade of silage baler machine in 2025.

Matched Equipment for 50-type Silage Baller

For better and easier silage processing, our silage bailer can work the the silage chopper and feeding silo to facilitate silage bale making. The collocation is shown below. If need more details, please contact us at any time!

Type 2: 9YDB-60 & T60 Maize Silage Baler and Wrapper (60*52cm)

9YDB-60 Silage Baler Machine

This 9YDB-60 bale wrapper is a new belt type of bale wrapping machine, which can use rope, plastic net or transparent film for feed bundling. It’s also fully automatic feeding, bundling, wrapping and cutting, without manual support. The diesel engine or electric motor can be chosen as the machine power. This upgrade makes our grass baler machine more comprehensive and uses a wider range of baling materials.

It can bale silage into Φ60*52cm round shapes, with a weight of 90-140kg/bale, and its capacity is 50-75pcs/h and 500-800kg/h. This model is more suitable for those who aim to make bigger round bales.

Advantages of Silage Baler Wrapper

Besides, our silage bailer is now upgraded, with the following advantages:

- 2.5-meter conveyor belt

- Dual-cylinder lower film applicator

- Chain-driven bales conveyor

- New film applicator, increasing capacity by 6 to 8 bags compared to the previous model and reducing packaging costs

Structure of Silage Hay Baling Machine

Technical Data of Forage Baler Machine

| Model | 9YDB-60 |

| Capacity | 50-75 bales/h |

| Bale weight | 90-140 kg/bale |

| Bundle size | Φ600*520 mm |

| Total power | 7.5+0.75 kw |

| Bundling method | Automatic |

| Bundling material | Rope, plastic net, transparent film |

| Wrapping material | Silage film |

| Size | 3500*1450*1550mm |

Matched equipment for 9YDB-60 Silage Baling Machine

Like the Model 50 equipment, this automatic baler machine can also be paired with a chopper or feed hopper, as shown below.

How to Install 60-type Baler for Hay and Silage?

As a professional silage machine manufacturer and supplier, we provide after-sales service(Instruction manual, installation guide, installation video, 24/7 online support, etc.)to ensure you use it smoothly.

T60 Corn Silage Baler

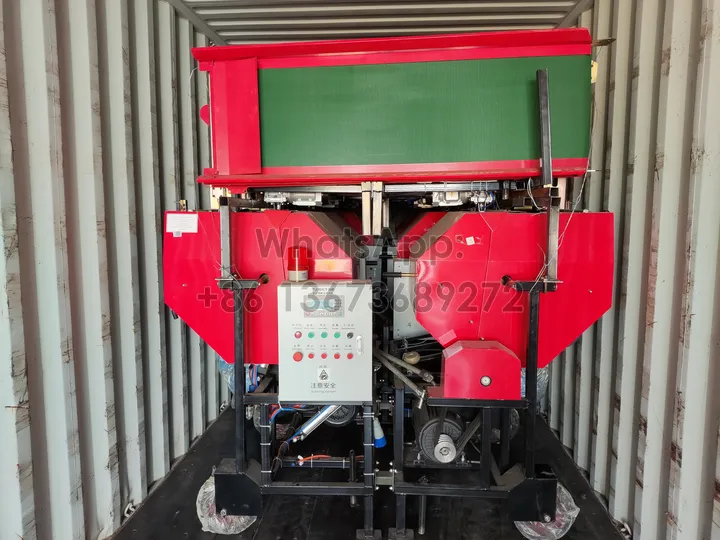

The T60 round bale wrapper is an electric motor-driven silage baler and wrapper designed specifically for medium to large-scale farms. Unlike the traditional 9YDB-60 baler and wrapper, the T60 features a dual-wrap structure and integrated design, delivering superior performance in wrapping efficiency, stability, and material leakage control.

This silage round baler wrapper can make Φ60*52cm silage bales, with a weight of 80-120kg/bale. It has an output 60-85bales/h.

If you’re seeking a round bale wrapper with a more compact structure, more stable wrapping, and less material leakage, the T60 is a model worth considering.

Advantages of Corn Silage Baler and Wrapper

- Electric drive structure for enhanced stability

- Transparent film baling for tighter bundling and wrapping for a better fermentation

- Integrated structure design for enhanced compactness and efficiency

- Chain conveyor system minimises material loss

Technical Parameters of T60 Silage Wrapping Machine

| Model | T60 |

| Bale size | Φ650*520mm |

| Bale weight | 80-120kg/bale |

| Capacity | 60-85bales/h |

| Matched power | 7.5kW-6 |

| Dimension | 4950*1500*1950mm |

| Weight | 1242kg |

9YDB-60 VS. T60 Silage Balers Comparison

If you’re comparing these two silage round bales, the following comparison will help you quickly determine which one better suits your ranch needs.

| Comparison item | 9YDB-60 | T60 |

| Equipment structure | Traditional structure | Integrated design (baler + wrapper combined) |

| Wrapping method | Single-wrap design | Dual-wrap design |

| Power source | Electric motor, diesel engine | Electric motor |

| Wrapping material | Transparent film | Yarn, plastic net, transparent film |

| Bale conveying Method | Longer chain conveyor | Chain conveyor |

| Spillage control | Less spillage | Standard level |

| Fermentation effect | Good fermentation performance | Enhanced sealed fermentation |

| Equipment advantages | Economical design, multiple power options | High efficiency, superior sealing, minimal loss |

Type 3: 9YDB-70 Fully Automatic Silage Baler Machine (70*70cm)

Compared to the above two mini silage baler machines, this type is a fully automatic silage baling and wrapping machine. It has the advantages of double film wrapping, high efficiency, and a motor power supply. Attention, this machine only uses the electric motor and is fully automatic during working. The baled silage has a high density, which is convenient for coating storage.

This silage packing machine can make Φ70*70cm silage bales, with a bale weight of 150-200kg/bale. I can produce 55-75pcs/h. It’s suitable for dairy & cattle farms that require big silage bales.

The 70 model silage baler wrapper is a high-capacity, automatic silage making solution designed for medium and large dairy farms, ensuring high-density bales, lower labor costs, and long-term airtight preservation.

In response to market demand, we have also developed a new model featuring waste recycling capabilities, which helps improve feed utilization rates.

What’s more, this grass baler machine can also bundle other dry and fresh grasses, and is necessary equipment for animal husbandry. After silage is wrapped, it has the following strengths:

- Locks in nutrients, better for livestock growth.

- It is good for storage and a balanced supply all year round.

- It stimulates appetite and promotes the development of livestock.

Advantages of 9YDB-70 Grass Baler Machine

- High-capacity silage baler for bigger round bales(Φ70*70cm)

- High-density silage bale for better fermentation performance & efficient silage preservation system

- Automatic silage baler wrapper for fully automatic silage bale wrapping, reducing labor costs

- Standardized hay bales(uniform bale dimensions and neat appearance), suitable for commercial sales

- Commercial silage baling machine with electric motor for stable operation

Matched Equipment for Fully Automatic Silage Baler and Wrapper Machine

This round silage baler machine is a fully automatic baling and wrapping machine. In order to improve production efficiency, we can match the automatic feeder with the Model 70 silage baler machine to achieve automatic production.

Advantages of this Matched Silage Baler Machine with the Feeder:

reduce manual intervention

reduce labor costs

improve production efficiency

simple operation of matched machine

Technical Specifications of Fully Automatic Silage Special Baler and Feeder Machine

9YDB-70 silage baler parameters

| Model | 9YDB-70 |

| Capacity | 55-75bales/h |

| Bale weight | 150-200kg/bale |

| Bundle size | Φ70*70cm |

| Voltage | 380V,50HZ,3 phase |

| Total power | 15.67KW (total 5 motors) |

| Air compressor volume | 0.36m³ |

| Feeding conveyor(W*L) | 700*2100mm |

| Film cutting | Automatic |

| Wrapping efficiency | 22s for 6-layer film |

| Size | 4500*1900*2000mm |

| Weight | 1100kg |

Feeder machine parameters

| Power | 3kw electric motor |

| Inside volume | 3/5m³ |

| Size(L*W*H) | 3100*1440*1740mm |

| Weight | 500/800kg |

Type 4: 9YDB-90 Silage Round Baler and Wrapper(90*90cm)

This Round Bale Wrapper is a fully automatic silage baler wrapper specifically designed for dairy farms, beef cattle operations, and large-scale ranches. This equipment efficiently bales corn stalks, forage grasses, Napier grass, and other silage materials into high-density bales while automatically applying film wrap. This process significantly enhances silage fermentation quality and minimizes feed waste.

The silage bale wrapper machine adopts a feed hopper, a scattered silage recycling system and a double-arm film wrapping system, making it attractive in the silage making solution.

It can make silage bales with a size of Φ90*90cm, has a bale weight of 300–500kg/bale, and a capacity of 55–60 bales/h. Among all models, this model produces the largest feed bales.

Advantages of Commercial Silage Bale Wrapper

- Integrated design, compact structure: hopper, waste materials recovery system & double-arm film wrapping

- High automation level: automatic feeding, baling & wrapping

- Stable operation: electric motor for a stable power supply

- Easy movement: big tires and frame for tractor, designed to move on the livestock farm

- Simple maintenance

- Short investment payback period

Technical parameters of Hay Grass Bale Making Machine

| Model | 9YDB-90 |

| Power | Electric motor, 39 kW |

| Bale size | Φ90*90cm |

| Bale weight | 300-430kg/bale |

| Capacity | 55-60bales/h |

| Machine size | ≥8100*2400*3100mmm |

| Machine weight | ≥4200kg |

| Hopper capacity | 3.5m² |

| Hopper height | ≥120cm |

| Hopper width | ≥170cm |

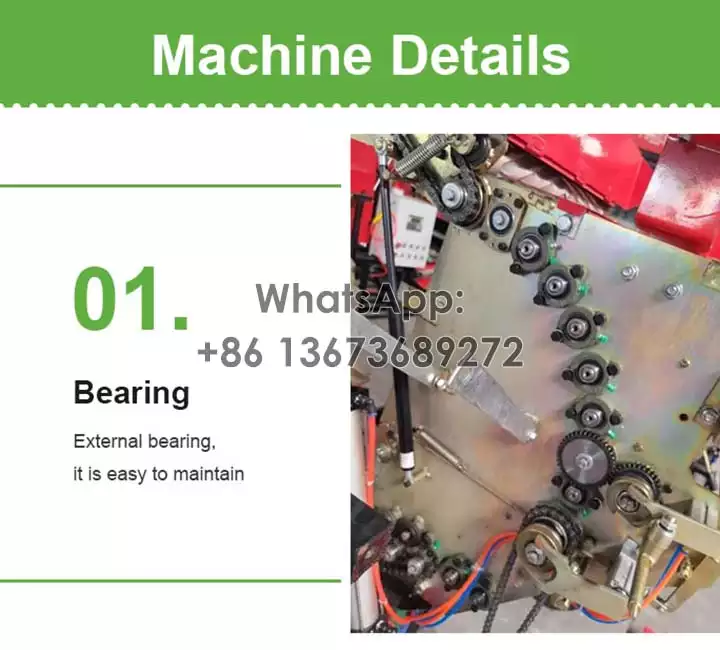

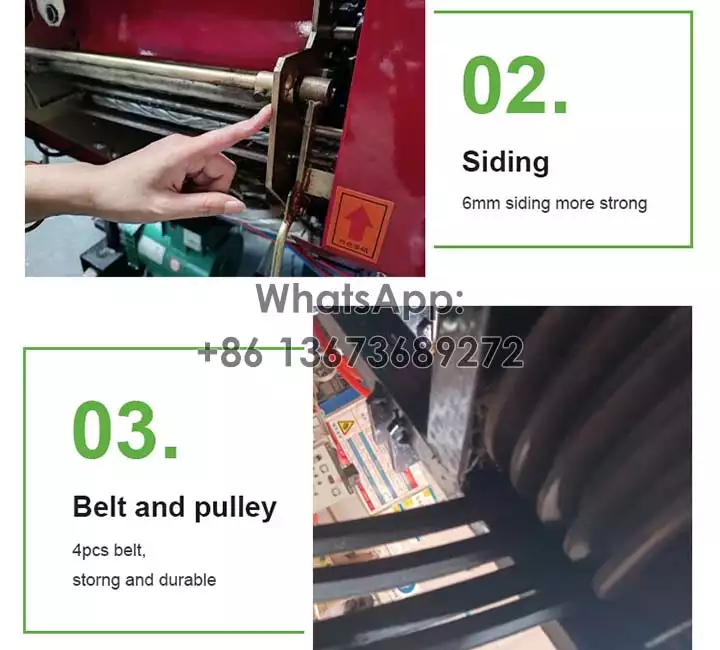

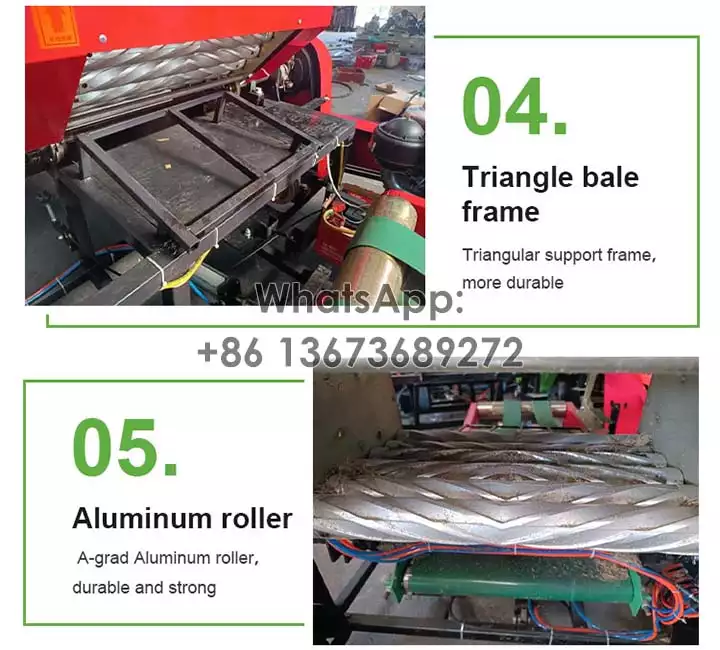

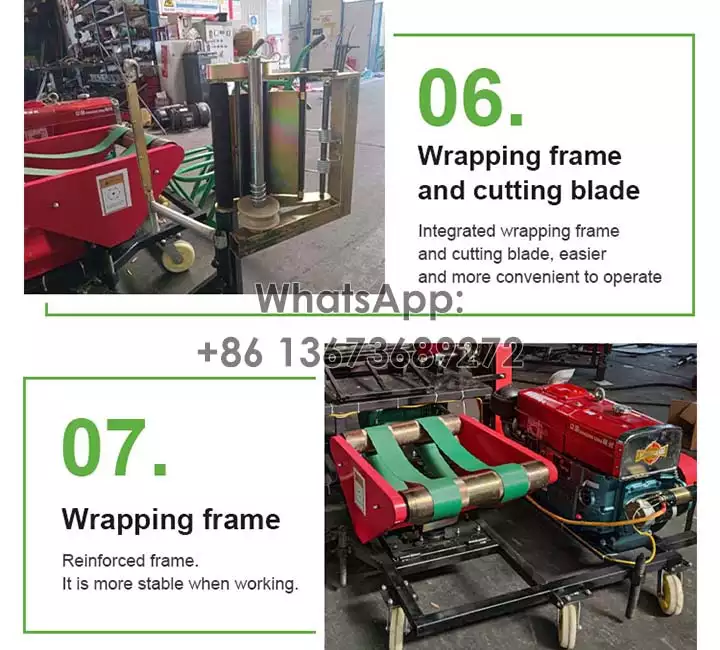

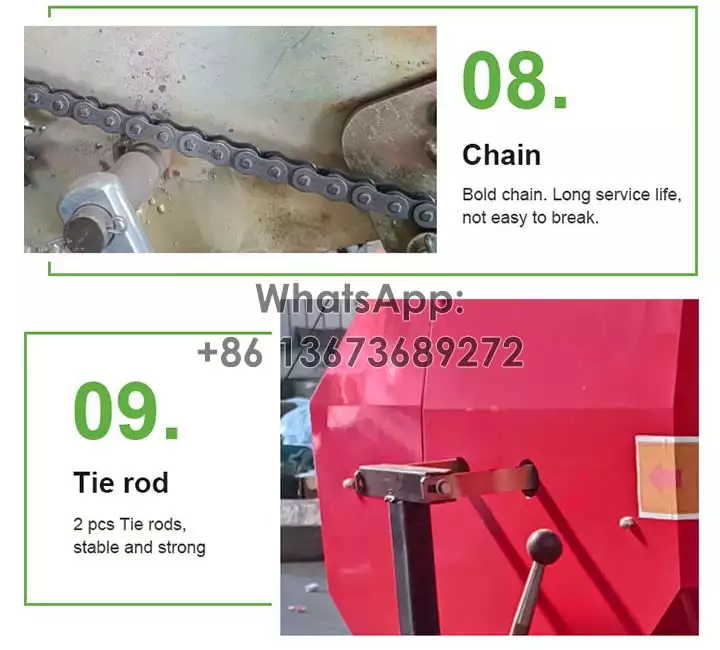

Newly Designed Structure Details for Silage Baler

As a professional manufacturer and supplier of baling and wrapping machines, our silage packing machine is constantly being upgraded. The latest silage making machine has been developed to be more reasonable in detail and made from high-quality materials, as shown below. If you are interested in this silage baling machine, please contact us!

What Materials Can Be Baled by Silage Round Baler?

As a professional silage producer and provider, the silage baling and wrapping machine from Taizy company has a wide range of applications. Such as wheat straw, sorghum straw, corn straw, soybean straw, hay, alfalfa grass, millet straw, pasture, crop straw, cotton stalk, peanut seedlings, garbage, etc.

Taking our previous customer as an example, he bought the machine for baling the garbage. It also works well. So, if you have doubts about the grass, welcome to contact us for more details!

Baling and Wrapping Materials Used for Silage Bales

If using the yarn/rope, plastic net, transparent film and forage film to bundle and wrap the silage, how to choose the proper quantity? The table below sets an example for your reference. When you have any need, please tell us your requirements, bale quantity, material to bundle the silage, etc., and then our sales manager will offer you the best solution.

| Name | Specifications |

| Yarn | Length per roll: 27cm Diameter: 20cm Weight: 4.2kg (approx.) Total length: 2500m Packaging: 6 rolls/bag Package dimensions: 62*45*27cm Approx. 70-85 bundles per roll |

| Plastic net | Length per roll: 50cm Diameter: 22cm Weight: 11.4kg Packaging: Plastic film Package dimensions: 50*22*22cm Approx. 280 bundles per roll |

| Transparent film | 2000m*525mm Approx. 330 silage bales per roll |

| Silage film | Length per roll: 25cm Diameter: 26cm Weight: 10kg Total length: 1800m Packaging: 1 roll/box Package dimensions: 27*27*27cm Two-layer wrapping: 75-80 bundles Three-layer wrapping: 50-55 bundles |

Working Process of Silage Baler and Wrapper

The working process follows the basic steps below:

- Raw Material Feeding

- Two types are available. One is manual feeding, and another one is machine feeding automatically. The raw materials are conveyed to the destination. When the materials are sufficient, it alarms. The conveyor belt will stop.

- Bundling

- The feed will be bundled in the specified location, and the rope or plastic net will bundle the feed into a round shape.

- Wrapping

- After bundling, use wrapping films to wrap the bundled feed to store for a long period.

Parts to be Necessarily Equipped for Silage Baler for Sale

- Air Compressor

- It’s closely connected with the automated opened silo. Generally speaking, the air compressor is necessary for realizing the automatic opening of the silo. It controls the opening of the silo after the feed is bundled.

- Baling Rope/Plastic Net

- This is used for bundling the feed during the working process. It’s also a consumable material. Thus, you’d better prepare enough materials for your production. You should attention, to the baling rope belonging to fibrous material, weathered after long-term storage. But it can be eaten together with the feed by the animals. However, the plastic net should be removed when you are ready to feed the animals.

- Wrapping Films

- When providing the silage baler for sale, we will prepare a roll along with the machine. Although there is a roll for your usage, it’s consumable. And it’s difficult to buy matched-wrapping films from locals. Therefore, preparing enough wrapping films is imperative.

- Trolley

- The trolley functions to save strength. After the feed wrapping, the silage baler and wrapper can automatically push the feed to the trolley. The trolley is under the control of the person. And then push the trolley, and put the wrapped feed in the proper location.

3 Basic Things to Consider When Buying the Silage Baler

- Firstly, the full automatic silage baler or not. But the fully automatic machine is widely and frequently used.

- Then, diesel engine or electric motor.

- Next, manually cut the wrapping film or automatically cut the wrapping film.

Our sales manager can provide the most suitable plan to meet your business demands.

Safety Applications and Precautions of Silage Baler

- Before starting the machine, check whether all parts are firm and reliable, and add enough lubricating oil to start the machine.

- Before starting the machine, you should pull the clutch handle to check the direction of rotation to see if it meets the requirements. It is strictly forbidden to reverse the machine.

- Before each work, run the machine empty for 2~3 minutes to confirm that the machine rotates smoothly and there is no other abnormality before the load test machine.

- This machine uses a motor as power, and a grounding wire should be installed at the grounding point of the machine.

- It is strictly forbidden to operate this machine after drinking.

Global Case of New Type Silage Baling Machine

With excellent performance and quality, Taizy round baler and wrapper has been successfully exported to many places around the world, such as Kenya, Malaysia, Algeria, Indonesia, Georgia, Thailand, etc. Widely used in the agricultural field of various countries, they are well-loved by farmers and have strongly promoted the process of international agricultural mechanization.

40HQ of silage bale making machines to Algeria

One distributor placed an order of 40HQ (total 16 silage balers) in 2021 for the first cooperation. He seized the good market chance and repurchased 2*40HQ goods, including silage balers and feeding bins, and expanded to feed pellet machines.

20GP of silage balers to Georgia tender project

Tender project from the Georgia government, after comparing different suppliers’ product quality,sales service and manufacturing strength, they finally chose to cooperate with us and purchased 20GP goods, including 4 sets of silage balers with electric motor, 1 set of silage baler with diesel engine and 2pcs of corn threshers.

9YDB-60 corn silage baling machine to Thailand

Our customer repurchased one 9YDB-60 Silage Baler and 2 rolls binding film and 20 rolls of plastic net. This is their fifth order. They have been working on the local government’s bidding project in 2024. They will attend an exhibition in the local area on February 28, 2025. As soon as our New Year holiday is over, we immediately arrange his order. Hope they can get more orders at the exhibition.

Feedback Videos from Taizy Worldwide Customers on Silage Baler

Mini silage baler machine feedback from Kenya

Corn silage baler feedback from Georgia

Fully automatic silage baler with feeder feedback from Kenya

Dry grass baler feedback from South Africa

PLC automatic silage baler feedback from Cameroon

Corn silage baler with silo feedback from the UK

Inquiry About Round Silage Baling Machine Price!

Want to make silage quickly and efficiently? Come and contact us, we will recommend you the most suitable equipment and give you the best offer. And we also have silage harvester and recycling machine to help you make better silage.