18TPD Automatic Rice Mill Production Line

18TPD automatic rice mill production line is a practical production line to process the paddy rice into white rice. Its output is 700-800kg per hour. It’s a complete rice mill plant, realizing full automation. Both round-shaped and long-shaped paddy rice can use, just choosing different rice millers. It can clean, de-stone, hull, separate, mill, polish, sort, grade, store, and pack all in one. Are you interested? Please contact us. We’ll offer suitable solutions based on your actual requirements.

Overview of Modern 18TPD Rice Mill Production Line

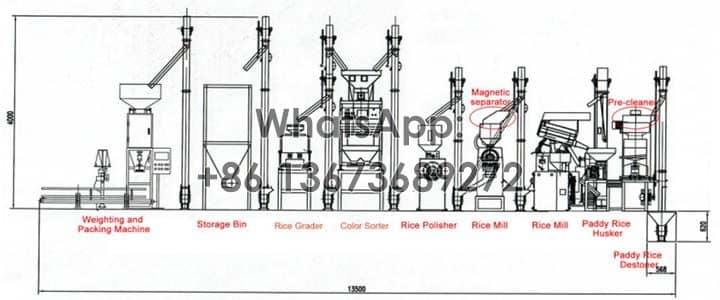

Structure of 18TPD Fully Automatic Rice Mill Production Line

This rice mill production line includes combined cleaner and destoner, rice husker, gravity separator, first rice mill, magnetic separator, second rice mill, rice polisher with water, color sorter, rice grader, storage bin, weighing and packing machine.

Why Choose Rice Mill Machine Twice?

From the 18T/D complete automatic rice mill production line, we find that it has first rice milling and second rice milling. The reasons are as follows:

- Low breakage. Adopting twice rice milling, it greatly reduces the broken rice rate, and you can get high-quality white rice.

- Large output. Two rice mill machines can mill rice without interruption.

Spare Parts List(Necessary parts for 1 automatic rice mill production line in one year)

| S/N | Machine | Name | QTY |

| 1 | Spare parts for Paddy Rice Husker | Rubber roller | 4 pcs |

| 2 | Spare parts for First Rice Mill | Sieve | 8 pcs |

| 3 | Spare parts for First Rice Mill | Press bar | 16 pcs |

| 4 | Spare parts for First Rice Mill | Emery roller | 1 pc |

| 5 | Spare parts for First Rice Mill | Screw | 2 pcs |

| 6 | Spare parts for Second Rice Mill | Sieve | 12 pcs |

| 7 | Spare parts for Second Rice Mill | Press bar | 6 pcs |

| 8 | Spare parts for Second Rice Mill | Emery roller | 1 pc |

| 9 | Spare parts for Second Rice Mill | Screw | 2 pcs |

Features of 18t Rice Mill Plant Production Line

- Stable performance, compact structure, and super quality.

- Less broken rice. Because this automatic rice mill production line adopts two rice milling machines.

- Easy operation, high rice precision, and convenient maintenance.

- All spare parts are made of high-quality materials, durable and reliable.

- Save labor and improve work efficiency. Due to the storage bin, workers don’t need to wait for a long time to package. After storing for a certain quantity, package work can start in an efficient way.

Differences between 15t and 18t Automatic Rice Mill Production line

- Output. Obviously, the output differs. One is 15t per day while another is 18t per day.

- Rice polisher with water. Compared to 15t rice mill plant production line, 18t complete production line has the rice polisher with water. It polishes the white rice with spraying water, making it whiter and lighter.

Why Choose Us?

We, Taizy Company, are a well-experienced agricultural machine manufacturer and supplier. We provide not only a series of rice mill plant, but also hay baler, corn seeder, vegetable transplanter, etc. That’s because we have the following advantages:

- Brand effect.

- After-sales service.

- Professional and skilled officers.

Successful Case: 4 Sets 18TPD Rice Mill Plants to Burkina Faso

This year, one customer from Burkina Faso asked about the automatic rice mill production line. He is running a large-scale factory and the required output was 700-800kg per hour. Besides, he wanted high-quality white rice for sale. So, our sales manager Emily recommended the 18TPD Rice Mill Production line to satisfy his business. He reviewed the production line and was very satisfied. He ordered 4 sets once. And in September, we have successfully exported to his country, Burkina Faso. He received the machines and good feedback came to us.