Corn silage harvesting machine for straw, grass cutting

Taizy Silage Harvester integrates crushing dry or wet silage, straw, stalk, grass, etc. into small pieces with rotary blades and recycling them. It’s able to crush the straw into small pieces less than 80mm, which can directly be used for silage feed.

This corn forage harvester works with a tractor(≥45HP). It has harvesting widths of 1.0m, 1.3m, 1.5m, 1.65m, 1.8m, and 2.0m, with a recycling rate of ≥80%. The stubble height is less than 80mm. Its capacity ranges from 0.25-0.72 hectares/h. If you have any doubts, please contact us immediately, and we’ll reply very soon!

Advantages of corn silage harvester machine

- This corn forage harvester can harvest, cut, smash and throw straw and stalks, which is multifunctional.

- Taizy has different silage harvesters for sale, like 1.0m, 1.3m, 1.5m, 1.65m, etc.

- The straw crushing and recycling machine has a working speed of 2-4 km/h and a capacity of 0.25-0.72 hectares/h, which is highly efficient.

- The stubble height is 8-15cm, adjustable.

- We provide customization services, such as big wheels, secondary crushing, with or without a basket, etc.

Technical parameters of forage harvester machine

Based on the harvesting width, we classify this hay silage harvester machine, as 1.0m, 1.3m, 1.5m, 1.65m, 1.8m, and 2.0m. It uses the tractor to work. The below is detailed information, and you can know the matched tractor power, size, weight, capacity, etc.

| Harvesting width | 1m | 1.3m | 1.5m | 1.65m | 1.8m | 2.0m |

| Engine (without basket) | ≥45HP tractor | ≥45HP tractor | ≥50HP tractor | ≥55HP tractor | ≥60HP tractor | ≥70HP tractor |

| Engine (with basket) | ≥60HP tractor | ≥70HP tractor | ≥75HP tractor | ≥90HP tractor | ≥100HP tractor | ≥110HP tractor |

| Dimension | 1.4*1.2*2.6m | 1.5*1.8*3.35m | 1.5*2.0*3.5m | 1.5*2.2*3.5m | 1.5*2.3*3.5m | 1.7*2.5*3.5m |

| Weight | 680kg | 700kg | 720kg | 790kg | 820kg | 850kg |

| Recycling rate | ≥80% | ≥80% | ≥80% | ≥80% | ≥80% | ≥80% |

| Fling distance | 3-5m | 3-5m | 3-5m | 3-5m | 3-5m | 3-5m |

| Fling height | ≥2m | ≥2m | ≥2m | ≥2m | ≥2m | ≥2m |

| Length of crushed straw | Less than 80mm | Less than 80mm | Less than 80mm | Less than 80mm | Less than 80mm | Less than 80mm |

| Rotating blade | 28 | 32 | 40 | 44 | 48 | 52 |

| Cutter shaft speed | 2160r/min | 2160r/min | 2160r/min | 2160r/min | 2160r/min | 2160r/min |

| Working speed | 2-4km/h | 2-4km/h | 2-4km/h | 2-4km/h | 2-4km/h | 2-4km/h |

| Capacity | 0.25-0.48hectares/h | 0.25-0.48hectares/h | 0.3-0.5hectares/h | 0.32-0.55hectares/h | 0.36-0.6hectares/h | 0.36-0.72hectares/h |

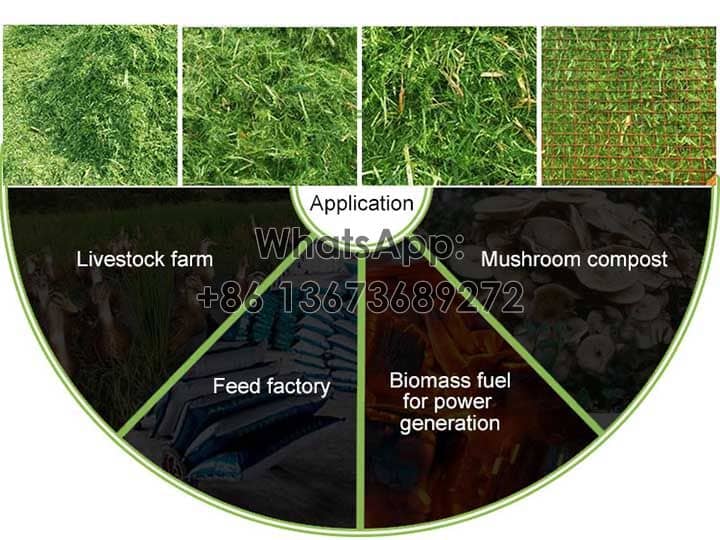

Applications of tractor-mounted mini silage harvester

This chaff harvester machine can chop and collect various stalks, such as corn stalks, cotton stalks, straws, banana stalks, sorghum stalks, grain stalks, grass, etc. The final product can be used to feed animal and add nutrition of soil etc.

After chopping and collecting crushed straws by the silage recycling machine, here’s where it can be used:

- Livestock farm

- Feed factory

- Biomass fuel for power generation

- Mushroom compost

If you’re interested in this grass harvester and recycling machine, welcome to contact us and we’ll provide more details for your reference.

Structure of silage harvester machine

Generally speaking, it consists of crushing chamber, hydraulic automatic unload device, crushed straw collection, tractor.

- Crushing chamber: a place for crushing the straws.

- Hydraulic automatic unload device: automatically unload, saving labor and time.

- Crushed straw collection: collect crushed straw, improving the work efficiency.

- Tractor: supply the driven power, connecting by PTO.

How does the silage harvester machine work?

Our corn stalk harvester utilizes the power output from the tractor’s power output shaft and transfers the power to the machine through the universal joint. The machine utilizes the gear speed change and triangle belt transmission to drive the shaft to rotate at high speed and cut off the straw. Please refer to the following video for details.

Customizable parts of corn silage harvester

As a professional silage equipment manufacturer, we can customize solutions to meet the needs of our customers. For the silage harvesting and recycling machine, the customizable parts are as follows:

Second crushing part

If want smaller stick pieces, then a second crushing is required. Based on the existing silage harvesting machine, a second crushing part is added in the location shown in the left picture.

Wheels

The original straw cutting and recycling machine doesn’t have wheels. These two wheels can protect the grassroots to second grow up after cutting. You can choose as you need.

Collection bin for crushed straw

The storage bin can be customized as you require. Some customers want the machine with the storage function, then the collection can be equipped. The capacity is 3cbm, 1000kg. It depends on the customers.

Wearing parts of corn silage harvester for sale

In Taizy, this pull-type forage harvester uses rotary blades to crush the straw. It can be used for 2 years. When using, attention to the field situation. And after 2-year usage, the rotary blades should be replaced.

Another 3 types of available forage harvester machines

Self-propelled forage harvester

This straw crusher adopts a unique “backward walking” design, moving backward during operation, which can adapt to the field terrain more flexibly, especially suitable for small plots or complex terrain. The blade system is optimized to efficiently crush the straw and evenly throw it into the field or collection bin, which is convenient for subsequent return to the field or recycling.

Corn silage harvester without basket

The binless grass harvester and recycling machine is designed to be thrown directly or transported externally, eliminating the need for a traditional bin structure and making the machine lighter and less costly. Its highly efficient crushing system can process stalks quickly and evenly distribute the crushed straw to the field through the spraying device, or directly transport it to the designated place through the external equipment.

Side-mounted silage harvesting machine

Side-mounted straw harvester and recycling machine is an agricultural machinery designed for grass, stalks, and other straws. By connecting with the tractor side-mounted, this equipment can realize walking, crushing and recycling at the same time. It is suitable for small and medium-sized plots of land, especially for small fields or hilly areas.

| Model | 9Q-900 |

| Connecting method | Hanging |

| Supporting power | 240hp |

| Size when working | 3870*2810*3720mm |

| Packing size | 2000*1800*1500mm |

| Weight | Net weight: 720kg Gross weight: 920kg |

Preoccupation of silage harvester

- Check and tighten the fasteners at the connections.

- Remember to remove the clay so as not to overload the machine work.

- Lack of oil in the bearing gap will cause high temperature, it should be added in time.

- Open the fan cover and check whether the screws on the hub of the fan wheel are loose.

FAQ of maize silage harvester

Q: If there are a lot of rocks in the field, will it affect the work of the machine?

A: Ask the customer to send the actual field pictures, and the small stones will not affect it.

Q: How often to replace the blade?

A: The machine can be replaced after 2 years of usage.

Q: Are the secondary crushing and wheels adjustable?

A: Yes, you can remove it if you don’t need it. It does not affect the normal operation of the machine.

Feedback of Taizy silage harvester from worldwide customers

After using our maize forage harvester, the customer praised the machine and sent us feedback videos.

Feedback about 1.3 silage harvesting machine from Malaysian customer

Feedback on 1.5m silage harvester from Cambodian customer

Contact us for more details!

As a silage machinery manufacturer and supplier, we also have silage baler, forage chopper machine, hay round baler, and other equipment for sale.

No matter what type you need, contact us and we will recommend the most suitable equipment to help your silage business according to your needs.