Combined Peanut Groundnut Shelling and Cleaning Machine

Combined groundnut shelling and cleaning machine is a combination of cleaning and shelling peanuts, with an output of 1000-8000kg/h. It can quickly and effectively strip peanuts from the shell.

This combined peanut shelling unit has a cleaning & shelling rate of ≥99% and a loss rate of ≤0.5%. The breakage rate is ≤5%.

Our industrial peanut sheller has features of high efficiency, low loss breakage and saving labor costs. Thus, it’s well-received by customers all over the world, like Zimbabwe, Ghana, Segnel, Pakistan, etc. If you’re interested, please feel free to contact us.

Advantages of industrial peanut shelling unit

- Capacity of 1000-8000kg/h. Our peanut sheller unit can shell groundnuts 1000-8000kg per hour, which is very efficient.

- Cleaning & shelling rate of ≥99%. Taizy combined groundnut shelling machine has cleaner and sheller, which can extremely fast clearing and shelling, up to 99% or more.

- Breakage rate of ≤5%. During the shelling process, this unit can maximize the integrity of the peanut kernel, with a ≤5% breakage rate.

- Suitable for various sizes of peanuts. By changing the screen, no matter what size and type of peanuts you have, our equipment can be suitable.

- High degree of automation. This machine has automatic feeding, automatic shelling, automatic screening and other functions, easy to operate, reducing manual intervention

- Long service life. The equipment is made of high-quality materials, with sturdy structure and strong durability, capable of long-term stable operation.

Technical parameters of combined groundnut shelling and cleaning machine

| Model | 6BHX-1500 | 6BHX-3500 | 6BHX-20000 | 6BHX-28000 | 6BHX-35000 |

| Capacity | ≥1000kg/h | ≥2000kg/h | ≥5000kg/h | ≥6000kg/h | ≥8000kg/h |

| Dimension | 1500*1050*1460mm | 2500*1200*2450mm | 2650*1690*3360mm | 2750*1800*3360mm | 2785*1900*3260mm |

| Total weight | 550kg | 1200kg | 2270kg | 2380kg | 2750kg |

| Cleaning motor | 1.5kw, 1.5kw | 3kw, 3kw | 5.5kw, 5.5kw | 5.5kw, 5.5kw | 5.5kw, 7.5kw |

| Shelling motor | 1.5kw, 3kw | 5.5kw, 4kw | 11kw, 4kw, 11kw | 15kw, 4kw, 15kw | 11kw, 7.5kw, 5.5kw, 18.5kw |

| Cleaning rate | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

| Shelling rate | ≥99% | ≥99% | ≥99% | ≥99% | ≥99% |

| Loss rate | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% | ≤0.5% |

| Breakage rate | ≤5% | ≤5% | ≤5% | ≤5% | ≤5% |

| Humidity | 10% | 10% | 10% | 10% | 10% |

As a professional manufacturer and producer of agricultural equipment, we offer five types of peanut shelling and cleaning machines. They’re respecitively 6BHX-1500, 6BHX-3500, 6BHX-20000, 6BHX-28000 and 6BHX-30000.

The output ranges from 1000kg/h to 8000kg/h, suitable for small, medium and large peanut shelling businesses. Therefore, if you are looking for a peanut shelling solution, contact us quickly for more details!

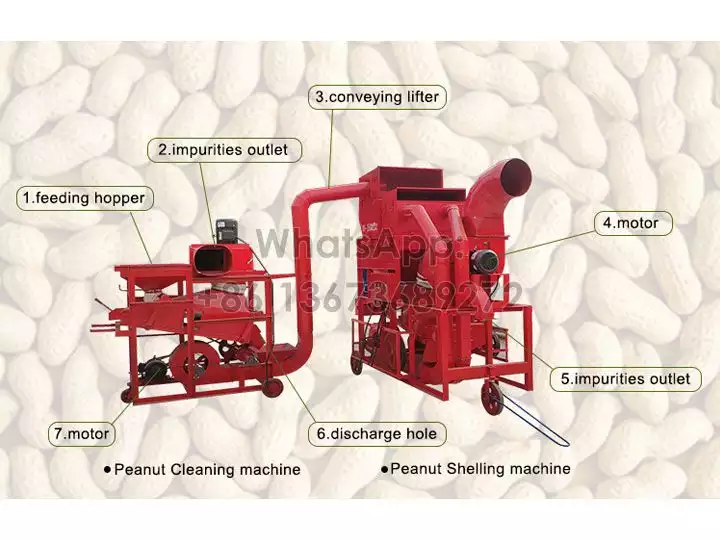

Structure of peanut shelling and cleaning machine

Our industrial peanut sheller consists of two parts, namely the cleaning machine and the shelling machine.

This equipment specifically includes feeder, discharge port (impurities, peanut kernels), conveyor elevator, motor, wheels, etc. Please see the picture below for more information.

Working principle of industrial peanut sheller unit

Taizy groundnut shelling unit separates peanuts from their hard shells through mechanical vibration and friction.

There are several working units inside the equipment, including feeding hopper, vibrating screen, shelling machine, wind separator and so on.

After entering from the feeding hopper, the peanuts are preliminarily screened through the vibrating screen, and then enter the shelling machine for shelling treatment. Finally, the peanut kernels are separated from the shells through the wind separator.

Accessories for commercial groundnut sheller and cleaner

Taizy industrial peanut sheller has spare parts, respectively screens, triangle belts, blower, wind wheels and rotors.

How about combined peanut shelling machine price?

When you buy peanut shelling equipment, you need to consider the cost of the machine.

The price of Taizy combined peanut shelling and cleaning machine varies depending on the capacity, configurations, market demands, transportation, etc.

If you want professional suggestions, please contact Taizy and our professional team will provide you with reasonable solutions.

Applications of large output peanut sheller

Taizy peanut shelling unit is suitable for large-scale peanut farmers and food processing enterprises. It’s widely used in:

- Agricultural planting areas

- Peanut processing factories

- Food processing enterprises

Besides, this combined peanut shelling and cleaning machine can get groundnut shells, also groundnut kernels. Both have different usages.

For groundnut shells, they can be produced into peanut shell pellets as fuel. Generally speaking, it’s a relatively hot biomass briquette fuel, mainly used to replace high-polluting coal for clean combustion. Of course, it belongs to Eco-friendly boiler fuel.

For peanut kernels, they can be produced into groundnut oil by the oil press machine. In fact, peanut oil is a very good edible oil. So, the main usage of peanut kernels is for oil extraction. However, the oil residue is a high-quality raw material for processing and making peanut protein.

Why choose Taizy combined groundnut shelling and cleaning machine?

- This combined groundnut shelling and cleaning machine has CE certificate, which has been officially recognized. It greatly guarantees the quality of the machine.

- Professional advice to customers. Our sales manager has rich knowledge about the combined peanut sheller unit. They can offer professional and suitable suggestions for customers, accelerating transactions.

- After-sales service. We have great after-sales service to prevent various problems appearing to obstruct your use.

Global cases of combined groundnut sheller unit

6BHX-1500 combined groundnut shelling and cleaning machine exported to Zimbabwe

Our sales manager Coco received an inquiry about the combined groundnut shelling machine from Zimbabwe.

This customer was interested in the 6BHX-1500 combined groundnut shelling and cleaning machine. He was impressed by the machine’s high output, great shelling results and good price. Finally, both reached an agreement.

6BHX-20000 automatic groundnut cleaning and shelling machine for Ghana

6BHX-3500 combined peanut cleaner and sheller for Pakistan

6BHX-3500 industrial combined groundnut shelling and cleaning machine for Mexico

6BHX-1500 groundnut shelling and cleaning machine for Tajikistan

Customer feedback about high-yield groundnut shelling and cleaning machine

Feedback from Tajikistan

Feedback from Ghana