What is fish feed pellet machine?

Essentially, this fish feed pelleting machine is the ideal equipment for those who invest in the fish feeding machine for aquarium and pets or have fish ponds. Besides, the fish feed pellet machine price is relatively cost-effective. Because it’s also a poultry animal feed pellet machine. Thus, the application is very wide. What’s more, it can produce puffed feed and floating and sinking feed. It depends on your demands. All in all, we have various types available for your options. Welcome to contact us for more details!

How does feed pellet machine work?

The fish feed machine uses the screw, extruding, heating up, until the material is discharged. So, the fish feed pellet machine has an easily understood working principle.

Firstly, put the raw materials into the hopper. And then the machine runs and brings the roller to convey raw materials to the screw. Next, the screw is working. At the discharge, there is a heating ring to function puffing. Finally, we can get the finished products.

Usually, the extruder machine for fish feed is used in large, medium, and small feed processing plants, aquaculture, livestock farms, and poultry farms.

How are fish feed pellets made?

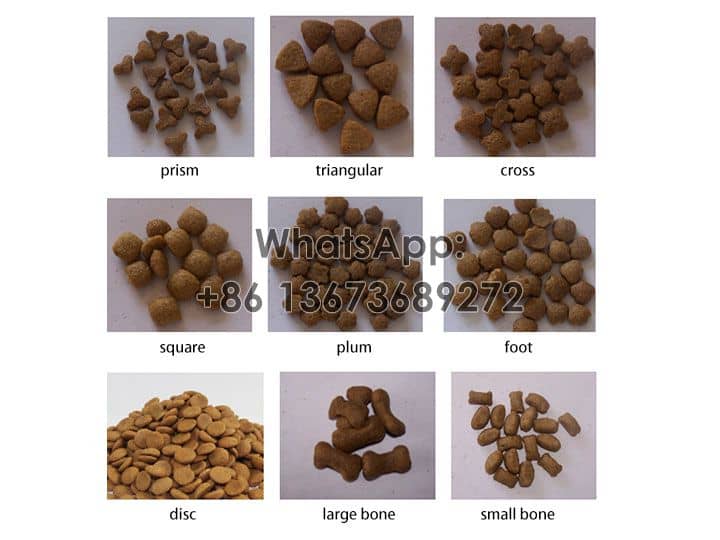

The fish feed or pet animal feed is commonly pellet or granules. If making feed pellets by the fish feed processing machine, it has sinking or floating types. Moreover, the feed has different diameters: φ1mm, φ1.5mm, φ2mm, φ3mm, φ3.5mm, φ4mm, φ5mm, φ6.8mm. Of course, the pet feed can be in different shapes, like triangle, pie, cat’s claw, bone , etc., very attractive.

What is fish feed formulation?

The fish pellet ingredients and pet dog feed are in different ratios. Now list the reference formulation for your reference when using the fish feed pellet machine.

Fish feed formula

The ingredients include cornflour, secondary flour, soybean meal, rice flour, etc. Every table represents each formulation.

| cornflour | secondary flour | flour | soybean meal | rice flour | fish meal |

| 50% | 15% | 10% | 5% | 10% | 10% |

| cornmeal | sub flour | flour | puffed powder | soybean meal | meat meal | animal fat | edible salt |

| 55% | 10% | 5% | 20% | 3% | 5% | 1.5% | 0.5% |

| secondary meal | rice husk meal | soybean meal | rape meal | cotton meal | cornmeal | fish meal | flour |

| 15% | 10% | 20% | 16% | 8% | 5% | 5% | 25% |

| corn and rice mixed flour | flour | wheat bran | soy protein | fish meal | rape meal | cotton meal |

| 20% | 25% | 5% | 20% | 5% | 16% | 8% |

| corn and rice mixed flour | flour | wheat bran | soy protein | fish meal | rape meal | cotton meal |

| 17% | 25% | 5% | 20% | 9% | 16% | 8% |

| corn and rice mixed flour | flour | wheat bran | soy protein | fish meal | rape meal | cotton meal |

| 11% | 25% | 5% | 20% | 15% | 16% | 8% |

The moisture content of the raw materials is between 15-18%.

Post-spraying treatment: After drying or air-drying, add 4-6% vegetable oil to adjust the moisture to about 8%.

Fishing feed

| cornflour | rice flour | flour | sub-flour | soybean meal | vegetable oil | water | binder |

| 20% | 5% | 20% | 50% | 5% | 10% | 18-25% | 2% |