Animal Feed Pellet Machine for Cattle, Chicken Livestock

Animal feed pellet machine specially produces animal feed for cattle, goats, and poultry, like chicken, and duck. This pellet mill machine has a simple structure, stable performance, and easy operation. Besides, the raw materials of the animal feed pellet mill are grass and grains, like corns, soybeans, rice husks, and others.

What’s more, our feed pellet mill has been exported to many countries and regions, and received popularity from our customers. Due to the small feed pellet machine, popular countries are as Philippines, Nigeria, Pakistan, Malaysia, Nepal, Australia, Ghana, etc. Looking forward to your inquiries!

Technical Specifications of Feed Pellet Machine

The animal feed making machine price differs based on the different configurations. We classify the machine model according to the mould plant diameter. Along with the bigger mould plate, the capacity increases.

Besides, the more capacity, we recommend the electric motor or diesel engine. You can contact us for more details. We’ll get back to you very soon.

| Model | Capacity | Power | Mould Plate Diameter | Size | Weight |

| KL-120 | 120kg/h | 3kW | 120mm | 750*320*610mm | 100kg |

| KL-150 | 150kg/h | 3kW | 150mm | 750*350*650mm | 190kg |

| KL-210 | 400kg/h | 7.5kW | 210mm | 1000*450*960mm | 230kg |

| KBL-260 | 800kg/h | 15kW | 260mm | 1460*460*1150mm | 360kg |

| KBL-300 | 1000-1200kg/h | 22kW | 300mm | 1360*570*1150mm | 450kg |

Reasonable Structure of Feed Pelleting Machine

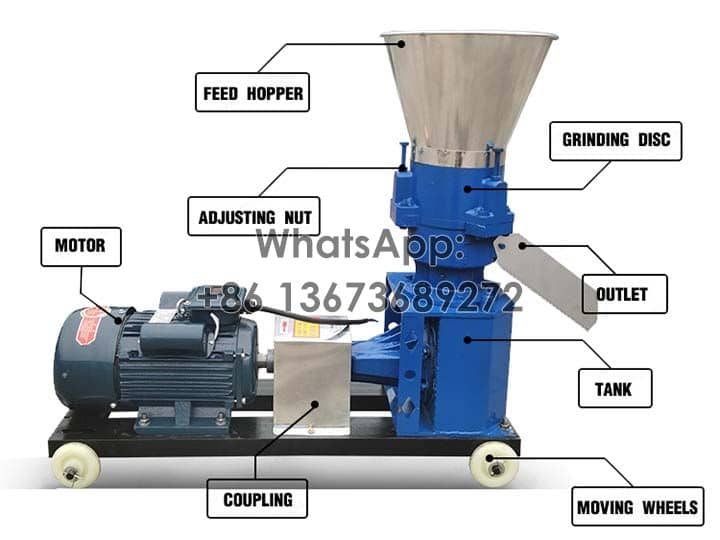

As a professional animal feed pellet machine manufacturer and supplier, technicians design the feed pellet machine catering to the market. It consists of the feed hopper, working chamber, power system, and gearbox.

In the working chamber, the roller and the mould plate are the consumable parts.

Working Principle of Animal Feed Pellet Machine

The working chamber is the spirit of the animal feed granulator. It has press roller, mould plate, and cutter. The milling feed rate and pellets length can be adjusted.

Firstly, put the raw materials into the feed bin. They will fall down onto s set of rotating rollers over the mould plate.

Then, materials will be squeezed between the surface of the mould plate and the rotating rollers. Pellets will come out of the die, and be cut into specified lengths by a sharp knife.

Features of Animal Feed Pellet Machine for Sale

- Three power sources. Electric motor, diesel engine, and gasoline engine are available. This flat die pellet mill can be used everywhere in the world, especially popular for areas with a shortage supply of electricity.

- Simple to use and clean. Only 1 or 2 workers are enough.

- Spare parts are easy to change, less cost for roller and dies.

- Compact structure and lightweight, convenient to move and suitable for small pellet production.

- Uniform pellet composition and neat shape. The particle diameter can be divided into: φ2, φ2.5, φ3, φ3.5, φ4, φ5, φ6, φ7, φ8 and so on.

Applications of Animal Feed Pelleting Machine

This feed pellet making machine can use corns, rice husk, cotton stalk, cottonseed skins, wheat bran, and all kinds of grain powder etc. After processing by this animal feed pellet machine, it can be breeding cattle, goat, pigs, chicken, duck, etc.

For example, refer to the cattle feed pellet formula, then you can clearly know how to mix the raw materials. And then using this machine to produce the required pellets.

Working Principle of Animal Feed Pellet Machine

The working chamber is the spirit of the animal feed granulator. It has press roller, mould plate, and cutter. The milling feed rate and pellets length can be adjusted.

Firstly, put the raw materials into the feed bin. They will fall down onto s set of rotating rollers over the mould plate.

Then, materials will be squeezed between the surface of the mould plate and the rotating rollers. Pellets will come out of the die, and be cut into specified lengths by a sharp knife.

Advantages of Pellets Processed by Feed Pellet Mill

During processing, the temperature is about 70°C, thus the protein freezes. The nutritional value increases and for animals, it’s easy to absorb. For pellets made by the animal feed pellet machine, its inner is ripening, outer is rigid enough. Owing to these characteristics, it’s suitable for long-term storage.

Feed Pellet Plant for Mass Animal Feed Production

We supply complete sets of flat die pellet mills for animal feed pellet production, providing complete solutions for different output levels of 500kg, 1000kg and 2000kg.

From raw material crushing, mixing to pellet pressing and cooling packaging, it realizes high-efficiency automated production and meets the needs of all kinds of farm scale.

Service Offered to Livestock Animal Feed Pellet Mill

As a well-known animal feed pellet machine manufacturer, we provide you with a full range of livestock and animal feed pellet production services, mainly including the following:

- Equipment supply: We provide flat die pellet mills of various specifications and capacities(120-1200kg/h), including complete sets of feed production equipment at different output levels, such as 500kg, 1000kg and 2000kg.

- Quality assurance: All products have passed strict quality testing to ensure that the feed pellet mill has superior performance, durability and reliability, to help customers improve economic efficiency.

- Customized solutions: Tailor-made animal feed pellet machine or production line design solutions according to your specific needs and farming scale to ensure an efficient and stable livestock feed pellet production process.

- Technical support: Equipped with a professional technical team, we provide equipment installation and commissioning, operation training, maintenance and other full technical support services.

- Raw material formula guidance: We cooperate with industry experts, research and develop feed formulas that meet the nutritional needs of animals for you, and give professional advice on the selection of raw materials.

- After-sales service: Taizy has established a perfect after-sales service system to ensure a quick response to your needs, and solve all kinds of problems in the process of equipment operation promptly.

Related Machines

One more thing to mention, we have the machine for fish feed, called fish feed pellet machine. Also, we provide the feed pellet production line, including the chaff cutter, crusher, mixer, animal feed pellet machine. When you’re going to purchase the machine, please contact us. We’ll recommend the most suitable one to you based on your actual demands.

Inquiry about Animal Feed Pellet Machine!

Want to do all kinds of animal feed production? We have a wide range of flat die pellet mill types to meet your needs. Contact us, we will design the best solution for you and provide the best quotation.