Cement Brick Making Machine for Sale

The brick making machine is specially designed for the production of various types of bricks. It is loved by customers from all over the world because of its simple structure, easy operation and high cost performance. As a senior brick machine manufacturer and supplier, we have a wide range of brick machine models.

In general, the block making machine for sale can be divided into the clay brick machine and the cement brick machine. There are different configurations under each type of brick machine, please read on for more information.

Type 1: Cement Brick Making Machine for Sale

The cement brick making machine is the hot-selling model in the market, and many customers come back to ask about the cement block machine. Our brick machine has diverse models and is easy to learn, and the price is suitable, is a good choice for investment for brick production.

In addition, our machines are often exported on a large scale because of their excellent performance, so if you are interested in brick machines, please contact us!

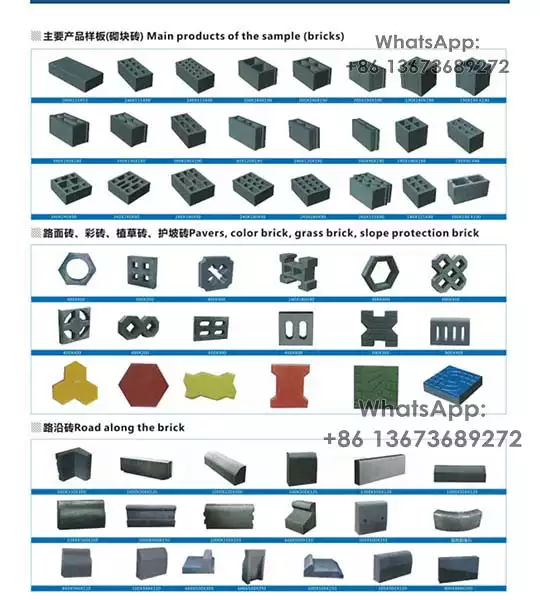

Various Sample Bricks and Bricks Moulds

The shapes of bricks that can be produced as well as the types of bricks that can be produced as mentioned in the picture above can be produced by our brick making machine.

Paver blocks, color blocks, grass bricks, slope protection blocks, cubes, blocks used along the road, etc. can be produced by Taizy block making machine.

Detailed Parameters of Cement Brick Machine for Sale

We have 10 models of cement brick machines for sale, each with different capacity and configuration details, the specific parameters can be found below.

| Model | Machine picture | Molding cycle | Equipped with power | Capacity | Plate size | Overall size | Weight | Operator required |

| DF2-45 |  | 45s | 1.1kw | Standard brick 240*53 *115mm 3600PCS Hollow bricks 390*190 *190mm 600PCS | / | 900*700*1150mm | 200kg | 1-2 |

| DF3-45 |  | 45s | 1.1kw | Standard brick 240*53 *115mm 8000PCS Hollow bricks 390*190 *190mm 1000PCS | / | 1100*1050*1300mm | 300kg | 1-2 |

| DF4-45 |  | 45s | 3.7kw | Standard brick 240*53 *115mm 12000PCS Hollow bricks 390*190 *190mm 1800PCS | / | 1250*1350*1550mm | 750kg | 2-3 |

| DF-diesel engine |  | 45s | 8hp | Standard brick 240*53 *115mm 3600PCS Hollow bricks 390*190 *190mm 600PCS | / | 1900*1000*1550mm | 250kg | 1-2 |

| DF4-35A without hopper |  | 35s | 4.8kw | Standard brick 240*53 *115mm 15000PCS Hollow bricks 390*190 *190mm 2400PCS | 850*550*30mm | 1250*1350*1550mm | 750kg | 2-3 |

| DF4-35A with hopper |  | 35s | 4.8kw | Standard brick 240*53 *115mm 20000PCS Hollow bricks 390*190 *190mm 3200PCS | 850*550*30mm | 1200*1280*1950mm | 780kg | 2-3 |

| DF4-35B without hopper |  | 35s | 6.3kw | Standard brick 240*53 *115mm 15000PCS Hollow bricks 390*190 *190mm 2400PCS | 850*550*30mm | 1250*1350*1550mm | 800kg | 2-3 |

| DF4-35B with hopper |  | 35s | 6.3kw | Standard brick 240*53 *115mm 20000PCS Hollow bricks 390*190 *190mm 3200PCS | 850*550*30mm | 1200*1280*1950mm | 830kg | 2-3 |

| DF4-40A without hopper |  | 35s | 7.5kw | Standard brick 240*53 *115mm 20000PCS Hollow bricks 390*190 *190mm 3200PCS | 850*550*30mm | 1500*1300*1800mm | 1100kg | 2-3 |

| DF4-40A automatic brick machine |  | 35s | 7.5kw | Standard brick 240*53 *115mm 24000PCS Hollow bricks 390*190 *190mm 3600PCS | 850*550*30mm | 1600*1300*2300mm | 1150kg | 2-3 |

Type 2: Clay Brick Making Machine – Free Buring Block Machine

This brick machine is a clay brick machine, i.e., a no-burn brick machine, which mainly uses clay for the production of bricks that can be made. This brick machine can be used together with other machines to produce clay bricks fully automatically.

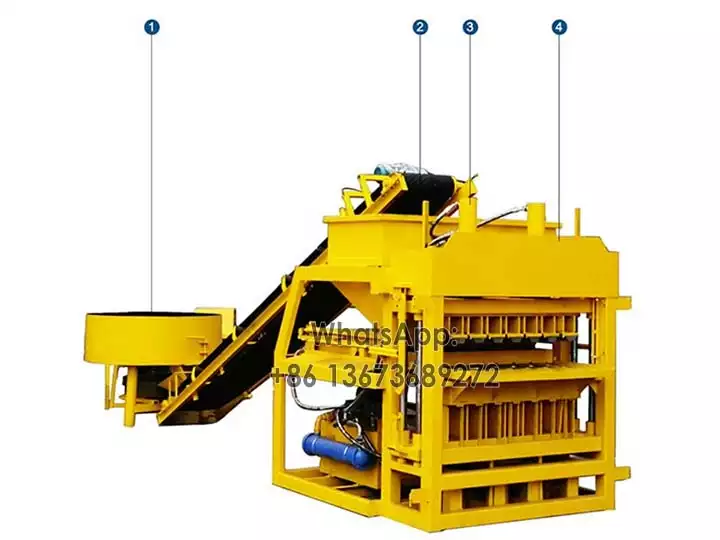

Structure of Fully Automatic Interlocking Brick Machine

This match helps buyers produce the clay block very conveniently and efficiently, which is very practical in the brick production industry.

If you’re interested, welcome to contact us!

| No. | Machine part name |

| 1 | Mixer |

| 2 | Belt conveyor |

| 3 | Hydraulic oil cylinder |

| 4 | Main block machine |

Clay Blocks Shapes & Machine Productivity

| Types | Brick picture | Size | Molding cycle | Qty/Mould | Qty/hour | Qty/8hr |

| Clay brick |  | 300*150*100mm | 10s | 7pcs | 2520pcs | 20160pcs |

What is the Flyash Brick Making Machine Price?

When you decide to buy a brick machine, you will definitely consider the price of the brick machine. And the price of brick machine is influenced by various aspects. For example, the manual cement brick making machine price is different from the price of a fully automatic clay brick machine. The price of the motor model of the brick machine and the diesel model of the block machine will also be different. In addition, the type of bricks that the customer wants to make should be considered. Because different types of molds are used, the price is also different.

So, when you want to buy a machine, you can tell our sales manager the shape of the bricks you want to produce and your budget, etc. Our sales manager can recommend the right solution for you according to your needs.

Package & Delivery of Taizy Brick Making Machine

After customers buy the brick machine from us, we will pack the machine after production. Because normally, it is shipped by sea to the customer’s destination, and various problems may be encountered at sea. The purpose of packing the fly ash brick making machine in wooden boxes is to better protect the block machine during the sea journey and to avoid any damage to the machine before it reaches its destination. The picture above is the packing of the brick machine.